Editors’ Picks

Found in Robotics News & Content, with a score of 69.09

See how Stratasys helps Don Schumacher Racing eliminate the time-consuming, trial-and-error process involved with machining out new components. With Stratasys 3D printing, they're able to produce parts in the exact form, fit and function of the parts that end up on the race cars, all before the next competition.

Found in Robotics News & Content, with a score of 65.37

Take a closer look at how Stratasys Additive Manufacturing is helping a company entrenched in Powersports vehicles drive innovation forward. Polaris is most commonly known for developing snowmobiles and off-road vehicles. With all the hands-on assembly work that the company does in the plant, they've begun to use 3D printing to change the way that they make tooling. Much of what the company does works around different styles of tooling. Polaris says the biggest benefit of partnering with Stratasys and their technology is the ability to iterate on new tooling designs.

Found in Robotics Companies & Businesses, with a score of 64.61

Stratasys Ltd. (Nasdaq:SSYS), headquartered in Minneapolis, Minnesota and Rehovot, Israel, is a leading global provider of 3D printing and additive manufacturing solutions. The company’s patented FDM®, PolyJet™, and WDM™ 3D Printing technologies produce prototypes and manufactured goods directly from 3D CAD files or other 3D content. Systems include 3D printers for idea development, prototyping and direct digital manufacturing. Stratasys subsidiaries include MakerBot and Solidscape, and the company operates a digital-manufacturing service comprising RedEye, Harvest Technologies and Solid Concepts. Stratasys has more than 2,500 employees, holds over 600 granted or pending additive manufacturing patents globally, and has received more than 25…

Found in Robotics News & Content, with a score of 57.35

Stratasys Ltd. has entered into an agreement with Xaar plc to purchase shares of Xaar 3D Ltd. that will increase Stratasys’ stake in Xaar 3D from 15% to 45%, with Xaar plc, through its fully owned subsidiary, Xaar 3D Holdings, having the remaining 55%. In addition, the agreement includes an option for Stratasys to acquire the remaining shares of Xaar 3D. The transaction is subject to Xaar plc shareholder approval. The strategic investment by Stratasys is intended to enable Xaar 3D to accelerate the development of its additive manufacturing solutions based on high-speed sintering (HSS) technology. These solutions are designed…

Found in Robotics News & Content, with a score of 53.06

Stratasys introduced a new work order management software solution for shops that provide centralized 3D printing services. GrabCAD Shop is designed to streamline work order management processes by improving the way engineers, designers and shop operators collaborate on 3D printing orders, the company says. According to Stratasys’ analysis, approximately 15% of work hours in a typical 3D print shop are wasted tracking down work order requirements and manually communicating status updates to engineers, designers and operators. GrabCAD Shop streamlines this process. Requiring no IT implementation support, the cloud-based software organizes print work requests, CAD files, and project specs all in…

Found in Robotics News & Content, with a score of 52.20

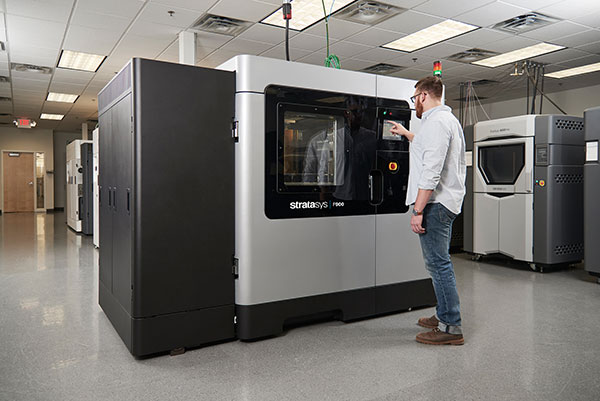

Stratasys has established an authorized materials partner program designed to expand the range of high-performance polymers available to manufacturers leveraging Stratasys’ fused deposition modeling (FDM) process in 3D printing applications. As an initial step, Solvay has been selected to help launch the program and deliver new polymers for the Stratasys F900 3D printer. Under the authorized materials partner program, Solvay will access tools and Stratasys expertise to develop materials aligned with the company’s quality and performance benchmarks. The partners will share an authorized partner materials roadmap to guide Solvay’s selection and development of materials for Stratasys FDM printers. “Stratasys is…

Found in Robotics News & Content, with a score of 50.23

Stratasys Ltd. introduced an acrylonitrile butadiene styrene-based carbon fiber material for its line of F123 Series 3D printers, the first composite material for the platform. Carbon fiber materials have proven popular on Stratasys’ industrial-scale FDM (fused deposition modeling) 3D printers for various end-use applications such as jigs, fixtures and tooling, company says. With FDM ABS-CF10, Stratasys now makes carbon fiber more accessible to the engineering and manufacturing community with high-performance F170, F270 and F370 3D printers. The material properties of FDM ABS-CF10, featuring 10% chopped carbon fiber, an alternative to metal parts. The material is said to be stronger and…

Found in Robotics News & Content, with a score of 49.68

Stratasys Direct Manufacturing is expanding its additive metals offering with the addition of VELO3D’s Sapphire 3D print system and Flow software. The Sapphire laser fusion metal additive manufacturing system allows for printing of complex part geometries with in-situ metrology, closed-loop control, and low-to-no support structures. The solution’s built-in tools include support generation, simulated print predictions, per-surface process application, slice composer and process review. This functionality allows for 3D printed production of complex metal components with more quality control, the company reports. “The Sapphire system from VELO3D is an important part of advancing our capabilities to include using additive metals in…

Found in Robotics News & Content, with a score of 49.65

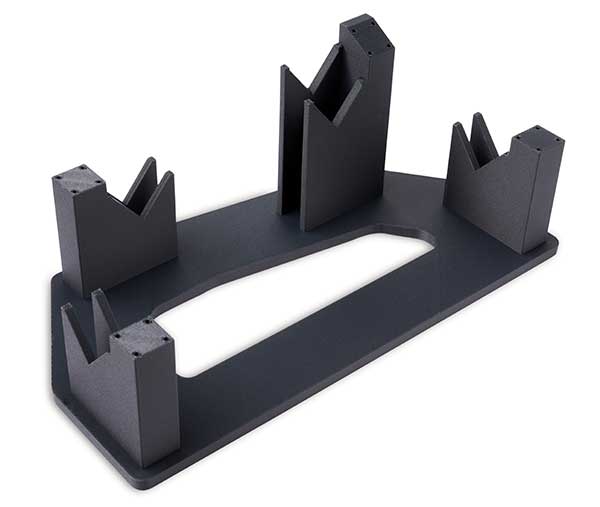

Stratasys is making additive manufacturing even easier thanks to a new collaboration with nTopology, innovator of next-generation design and engineering software. The two companies are providing a series of accessible, customizable design for additive manufacturing workflows for their users, starting with the FDM Assembly Fixture Generator. Stratasys FDM printers have become powerful, supporting advanced materials like Nylon 12 Carbon Fiber and reaching accuracy and reliability required for use on commercial airplanes and even the International Space Station. But designing with existing engineering software tools still creates long lead times, slowing additive manufacturing's march to pervasive adoption. The new Stratasys |…

Found in Robotics News & Content, with a score of 49.26

Stratasys Ltd. announces a new multi-year technical partnership agreement with Team Penske to continue to incorporate use of 3D printing on all Team Penske NASCAR, INDYCAR and IMSA SportsCar teams. “Stratasys has consistently contributed to our ability to reach new solutions for improving our race performance ahead of the competition,” says Team Penske President Tim Cindric. “Our 3D printing strategy has always been to produce high-quality parts for our racing operations in the shortest amount of time, and the ever-evolving additive technology from Stratasys gives us confidence in our approach.” Team Penske and Stratasys have worked together through five championships…

Found in Robotics News & Content, with a score of 48.92

Aurora Flight Sciences has been developing unmanned aerial vehicles (UAVs) for more than three decades. Aurora teamed with Stratasys to develop a notably complex 3D printed jet-powered UAV. Aurora Flight Sciences in Manassas, VA, has been developing unmanned aerial vehicles (UAVs) for both the civil and military markets for many years. However, with advancing customer needs and requirements, its research and development center is using Stratasys 3D printing technology more frequently for production parts and tooling to help bring new innovations to unmanned flight. Recently, engineers at Aurora and Stratasys embarked on an ambitious project: to build a jet-powered, thrust…

Found in Robotics News & Content, with a score of 45.67

Stratasys Ltd. is reducing its global workforce as part of a strategic plan to accelerate growth with a leaner operating model. This resizing, advanced sooner due to the impact of COVID-19, will affect approximately 10% of employees, and is designed to reduce operating expenses as part of a cost realignment program to focus on profitable growth. The company expects the vast majority of the reduction to take place in the second quarter and to complete the reduction during the third quarter of this year. “This reduction in force is a difficult but essential step in our ongoing strategic process, designed…