Editors’ Picks

Found in Robotics News & Content, with a score of 12.77

…the assembly and installation of long-travel motion systems including gantry and linear robots. The company said its new design, which includes a lower static toothed belt, also strengthens ServoBelt’s ability to non-destructively withstand high-force events, such as carriage crashes. Design changes to simplify integration In earlier designs, the belt adhered to its aluminum carrier using 3M’s VHB adhesive tape. While strong, the VHB complicated the assembly and installation process, requiring integrators to accurately apply the adhesive tape on site at the actuator’s end-use location. This process also made it difficult to splice sections of ServoBelt together - which Bell-Everman said…

Found in Robotics News & Content, with a score of 11.95

…RobotStudio AR software speed up deployment Unlike conventional two-dimensional gantry systems traditionally used in electronics manufacturing, GoFa cobots can offer full six-dimensional motion across their entire workspace upon delivery, without requiring additional calibration work. ABB said this design can provide the flexibility and mobility to handle a broader range of tasks. GoFa’s compact and portable design allows it to be easily integrated into existing production lines without the need for expensive customization. ABB said its GoFa robot arms with the Ultra Accuracy feature can be introduced into production with minimal installation and deployment time, as the calibration is done in…

Found in Robotics News & Content, with a score of 11.70

…vertical and horizontal machining, turning and milling, bridge and gantry, and machining accessories. Their manufacturing services help different industries with repair and manufacturing processes such as engineering and automation, factory maintenance, legacy overhaul and third-party spare parts. Specifically in the United States, JMT serves the automotive, defense, die and mold, and medical sectors. “The creation of a global partnership of Jupiter Machine Tool, Meltio and UnionMT, located on three continents is extraordinary and exciting,” said Ray Whitehead, CEO of Jupiter Machine Tool. “Our tri-cultural synergy blended with diverse global technology results in the design and manufacture of 3 and 5-axis…

Found in Robotics News & Content, with a score of 13.21

…Unmatched speed with exceptional reach: Unlike traditional industrial robots, gantry, SCARA or delta robots, the HKM1800 achieves an impressive pick rate of over 2000 articles per hour, making it the fastest robot currently available on the market, according to Cognibotics. The HKM1800 also covers a workspace of 10m. Versatile range: With the capability to handle items weighing up to 7.5kg in various sizes thanks to a smart tool changing system, the HKM1800 offers versatility and adaptability for a wide range of applications. Innovative technology: Featuring a novelty arm system configuration based on proven industrial components, including Active Motion Stabilization, the…

Found in Robotics News & Content, with a score of 15.19

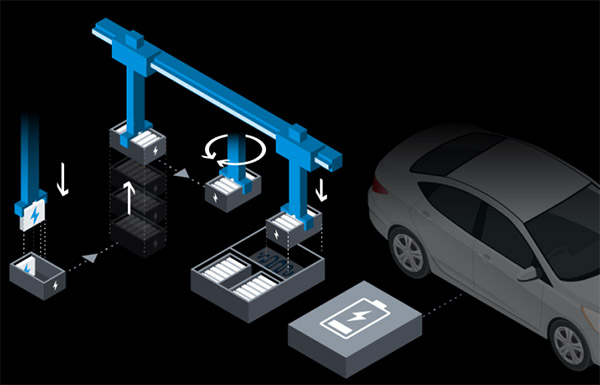

…modules based on present needs, with the ability to scale as business grows. The company’s end-to-end automation systems combine gantry robots, intelligent software, automated storage and retrieval systems (AS/RS), automated guided vehicles AGVs, conveyors, shuttles, and palletizers. Cimcorp offers end users continuous maintenance services, including spare parts, training, and 24/7 support, to help its customers secure a lifecycle of 20 years or more for their automation technology.

Found in Robotics News & Content, with a score of 11.56

…maintenance. Optimized truck loading results in less traffic and consequently reduces environmental impact.” Cimcorp’s end-to-end intralogistics systems incorporate modular gantry pickers, AGVs, and palletizers, according to its website. The company said its grocery retail distribution systems provide fast and efficient deliveries of fresh produce without picking errors or delays, even in times of increasing labor challenges. Cimcorp said its order picking system will take care of repetitive lifting of heavy objects, leading to a safer work environment for REWE’s employees.

Found in Robotics News & Content, with a score of 40.11

Pick-and-place robots come in many different forms, from gantries and deltas to robotic arms and cobots. Each has a specific niche within the broader scope of all pick-and-place applications. Read this blog to learn about each, how they work, and their strengths and weaknesses.

Found in Robotics News & Content, with a score of 13.32

…to containerize inventory into totes. It combines mobile robots, gantry systems, robotic arms, and a new ergonomic employee workstation. “From our latest robotic arms like Sparrow and Cardinal, to our first autonomous mobile robot, Proteus, we’re excited to see the impact our technology is having in Amazon’s operations,” wrote Scott Dresser, vice president of Amazon Robotics, in a blog post. “By reimagining how we store and manage inventory at our sites, Sequoia will help us delight customers with greater speed and increased accuracy for delivery estimates, while also improving employee safety at our facilities.” Sequoia designed to accelerate fulfillment The…

Found in Robotics News & Content, with a score of 8.40

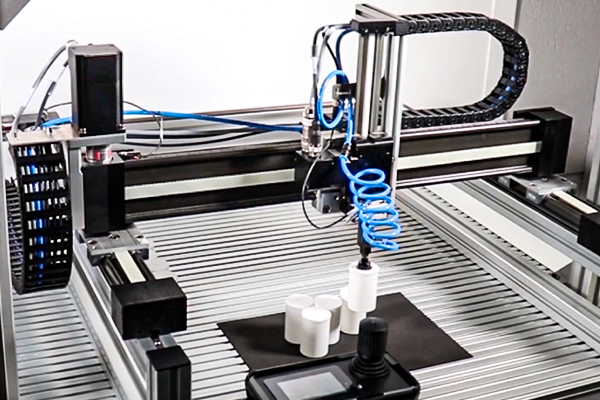

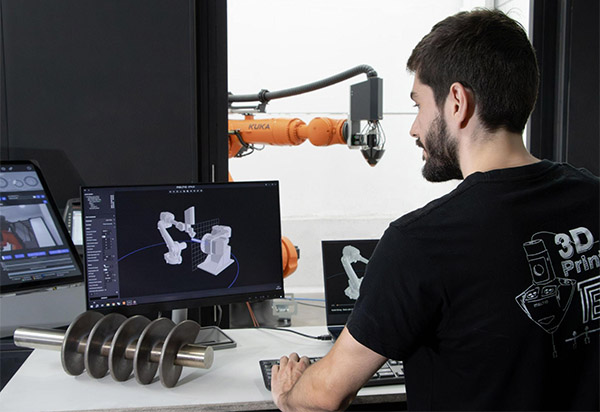

…can turn almost any CNC machine, robotic arm, or gantry system into a hybrid manufacturing center. Meltio Robot Cell comes pre-integrated The Meltio Robot Cell allows standard metal 3D printing starting from a build plate in a factory, as well as for part repair or feature addition, said the company, whose formal name is Directed Metal 3D SL. By standardizing the integration of the 3D printer, robot, and software, Meltio said it can provide competitive lead times. Meltio Robot Cell capabilities Meltio listed the following technical specifications: Easy to install, with all parts included Turnkey solution Best-in-class components Safe, tested,…

Found in Robotics News & Content, with a score of 7.83

…it said “turns almost any CNC, robotic arm, or gantry system into a powerful hybrid manufacturing center.” Both systems use the company's patented LMD-based process to make parts of both wire and powder simultaneously with the same printhead. Meltio Space is designed to “bridge the gap between additive manufacturing users and robotics,” according to the company. The new software integrates a six-axis robot manipulator and two-axis workpiece positioners to transcend traditional three-axis systems and open new possibilities for metal 3D printing, said Meltio. The company claimed that it will increase the reliability and accuracy of additive manufacturing for metal parts.…

Found in Robotics News & Content, with a score of 10.19

…Plus, modular systems can further reduce costs through a gantry design and high-density floor-based storage. In this setup, products are stored in plastic crates, stacked directly on the warehouse floor. Gantry robots can access any SKU, at any time, from overhead, eliminating the need for expensive racking or shelving systems. Myth 4: Automated systems are difficult to learn and maintain With any automation project, it’s true that warehouse managers and staff need to prepare for change. This includes learning how to operate, maintain, and supervise their automation system. The good news is that upskilling efforts don’t need to be a…

Found in Robotics News & Content, with a score of 6.14

…interface, noted the company. “The FMCP-UR can control turntables, gantry systems, conveyors, transfer tables, and any combination of linear and rotary servo axes up to the 10th axis—all under the UR+ partner umbrella,” said Festo. It said it plans to display full 10-axis motion at Automate, which runs from May 22 to 25. The Festo UR multi-axis system controls up to four axes: UR cobot with optional E30 smart magnetic gripper, teach pendant, and the seventh axis. Scan QR code for virtual reality image. Source: Festo FMCP-UR can be tailored to the application The FMCP-UR has specific features to interface…