Editors’ Picks

Found in Robotics News & Content, with a score of 71.61

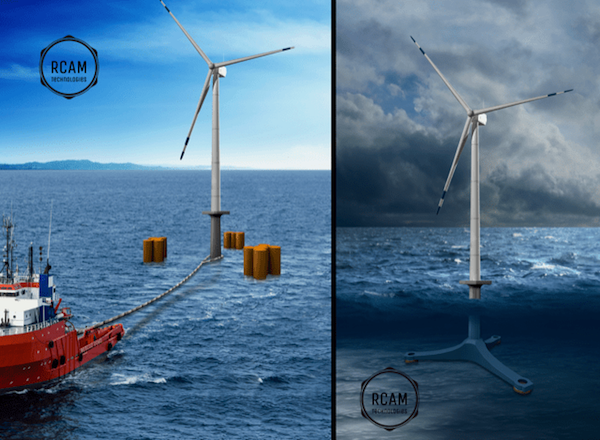

…collaborating to develop wind energy components using 3D printed concrete. Accucode is a leading technology integrator and IT service provider and RCAM Technologies specializes in mega-scale concrete construction methods. This announcement comes after RCAM Technologies secured $250,000 from the Colorado Office of Economic Development and International Trade's (COEDIT) Advanced Industries Accelerator Grant Program. The grant was awarded to RCAM Technologies for developing a 3D concrete printed wind turbine foundation that will reduce offshore deployment costs by up to $4M per foundation and $400M per wind plant. RCAM will use the funding to expand its 3D concrete printing capabilities at two…

Found in Robotics News & Content, with a score of 33.12

…replacing and eliminating more expensive and inferior building materials, causing the printed structures to be stronger and safer. Utsing concrete will reduce the cost by at least 30%, as well as making the structure more fire resistant than traditional methods. This home will have the strength to last into the next century. SQ4D Inc. Is a 3D printer manufacturer from Patchogue, NY, that produces consumer and business grade 3D printers and 3D printing services, as well as development of industrial-grade 3D home and building printers. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 27.24

…to create automated plants using industrial robots and 3D printing to build everything from aircraft wings to construction site installations. ETH Zurich researchers Andrea Perissinotto, Oliver Harley, and Matthias Leschok applied their expertise in robotics, engineering, and fabrication to found SAEKI in 2021. During their studies and industry collaborations, the trio said they identified the need to scale up additive manufacturing (AM) processes for large-scale applications such as bespoke concrete formwork. “Currently, to develop a lightweight carbon-fiber element or to build a topologically optimized concrete floor slab, buyers would have to wait months and spend vast sums of money to…

Found in Robotics News & Content, with a score of 23.92

…manage the entire manufacturing process using our metal 3D printing technology consisting of a Meltio head integrated in a robotic arm and in a safe environment, in order to just produce parts,” said Alejandro Nieto, Meltio Engine product manager, in a release. Linares, Spain-based Meltio said it has developed high-performance, affordable, and easy-to-use metal 3D printing systems using wire laser metal deposition (w-LMD) technology. The company said its portfolio includes the Meltio M450 metal 3D printer and Meltio Engine Integration, a 3D printing module that can turn almost any CNC machine, robotic arm, or gantry system into a hybrid manufacturing…

Found in Robotics News & Content, with a score of 23.21

…Diamond Age said its robotics-as-a-service (RaaS) offering combines 3D printing, mechatronics, and robotics to address the labor shortage and reduce construction cycle times from nine months to 30 days. “Affordable housing is impacting people on a global scale,” said Jack Oslan, co-founder and CEO of Diamond Age. “As the average age for first-time homebuyers has moved from mid-20s to mid-30s, there's an increased demand for more rental property—forcing the entire hierarchy of renters into a more competitive market for 'quality' housing.” “Helping the next generation of homebuyers get into their first house faster helps the entire ecosystem of housing,” he…

Found in Robotics News & Content, with a score of 22.96

…CRP Technology’s Rapid Prototyping Department has used the 3D printing technology called HSS (High Speed Sintering) and the Windform P1 isotropic material. “Following the intensification of the emergency due to the lack of fundamental devices for the care of patients affected by COVID-19,” says Franco Cevolini, vice president and technical director, CRP Technology, “we want to give a concrete sign of our support. We 3D printed emergency valves for ventilations and several 'Charlotte valves.'” “Charlotte valves” are link components for emergency ventilator masks, realized by Isinnova on Dr. Renato Favero's idea and project, adjusting a snorkeling mask already available on…

Found in Robotics News & Content, with a score of 18.72

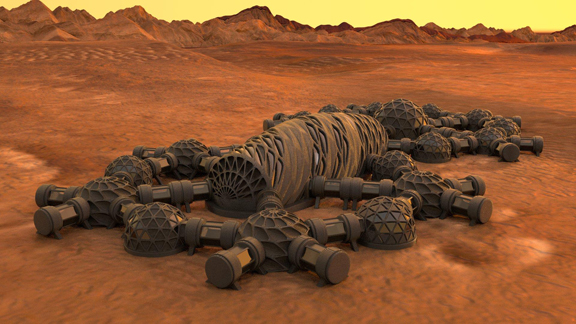

…PR, writes, “NASA’s Swamp Works lab is experimenting with 3D-printing habitable structures using a process called robotic extrusion, and a composite material made up of loose sediment (soil, dust, broken rock, etc.) and recycled plastic. The sediment, known as regolith, can be widely found on Earth, other planets, the moon, and even asteroids ... Based on NASA specifications, Autodesk’s Advanced Consulting team designed the barrier using tools such as Fusion 360 and PowerMill to comply with structural as well as robotic extrusion requirements while achieving significant weight reduction. Autodesk also developed the software to control the industrial robot arm ...”…

Found in Robotics News & Content, with a score of 15.19

…solicit direct feedback from AM power users to solve concrete problems without long feedback cycles. The participants included representatives from the AM value chain, including Voestalpine, Eckhart, EOS and Tenco. Alignment on Data-Driven Automation Features 3YOURMIND's Agile Manufacturing Execution System is now available. Image courtesy of 3YOURMIND. All participants connected around the vision of data-driven production floor automation, according to the company. The Agile MES Early Access Program offered core features out-of-the-box; based on previous customer requests. Those included smart part prioritization, schedule overview of production resources and the ability to create custom AM workflows that match the specific processes…

Found in Robotics News & Content, with a score of 13.03

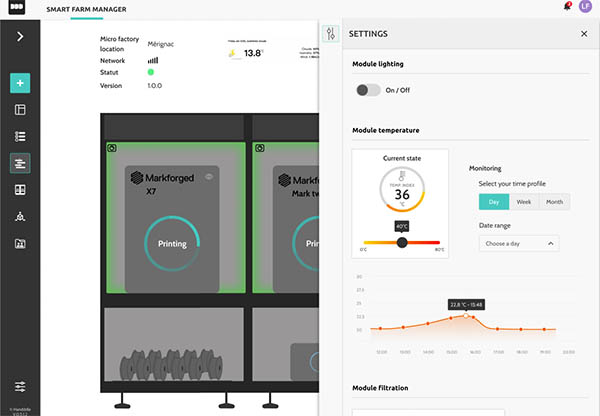

…kanban inventory system. “Markforged is known for its 3D printing reliability and repeatability, enabling production of industrial parts at scale,” said Julie van der Hoop, product manager at Markforged. “However, some industries or critical parts require clear reporting on constant production parameters, event history, and production data for certification before they can be put to end use.” “This integration is intended to make it seamless to import, slice, print, and monitor, with all of your production data in one place,” she added. Integration to improve AM production consistency Handddle and Markforged said their integration is designed to provide ex-situ process…