Editors’ Picks

Found in Robotics News & Content, with a score of 55.02

…out of Harrison, Ohio, announces a distribution partnership with BASF 3D Printing Solutions (BASF 3DPS). CI’s high-temperature Small Area Additive Manufacturing (SAAM HT) machine will now offer BASF 3DPS’s ABS plastic, carbon fiber PET and recycled PET materials. Ultrafuse ABS is created from acrylonitrile, butadiene and styrene polymers. It has a strong, flexible and heat-resistant nature, according to the companies. It can be used for those looking to manufacture low-cost prototypes, or anyone who wants to create plastic products with ease. Ultrafuse PET CF15 from BASF 3DPS combines processability and low moisture uptake with strength and rigidity. With this PET…

Found in Robotics News & Content, with a score of 54.06

BASF New Business GmbH has formally agreed to acquire the online 3D printing service provider Sculpteo. The agreement was signed on November 14, 2019, and is expected to become effective in the next few weeks pending regulatory approval by the relevant authorities. The acquisition of the French 3D printing specialist based in Paris and San Francisco will enable BASF 3D Printing Solutions GmbH, a wholly-owned subsidiary of BASF New Business GmbH, to market and establish new industrial 3D printing materials more quickly. Sculpteo’s management team fully supports the acquisition and will remain in place to provide customers and partners with…

Found in Robotics News & Content, with a score of 36.66

HP announced new alliances with both BASF and Oechsler to expand the advancement of industrial 3D printing and digital manufacturing. The expanded alliance with BASF centers around HP’s newly announced polypropylene material for additive manufacturing. The HP 3D High Reusability PP enabled by BASF was developed and qualified for HP’s Jet Fusion 5200 Series 3D printing solution to enable companies to design and produce 3D printed parts faster, more cost-effectively, more sustainably, and at higher volumes, the company says.http://www.hp.com/go/3Dprinting. “The advancement of our long-standing partnership with HP truly demonstrates our shared vision to help transform industries, enable sustainable production, and…

Found in Robotics News & Content, with a score of 36.19

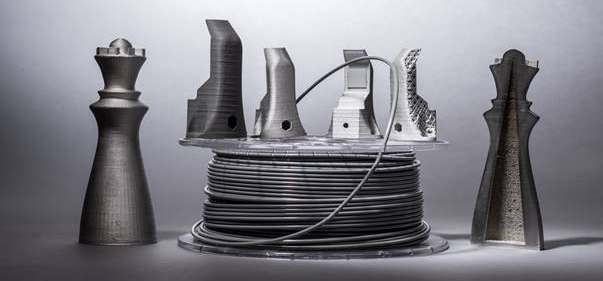

With Ultrafuse 316L, BASF 3D Printing Solutions launches a metal-polymer composite for fused filament fabrication (FFF). It enables the safe, simple, and cost-efficient production of fully metal parts for prototypes, metal tooling and functional metal parts in 3D printing, according to the company. After the subsequent industry-standard debinding and sintering, the final 3D printed part is 316L stainless steel. FFF refers to a 3D printing process in which parts are built up layer by layer from moldable material. Ultrafuse 316L, a metal filament with polymer content, uses the same process; first, a suitable 3D printer builds a part layer-by-layer, with…

Found in Robotics News & Content, with a score of 35.15

BASF 3D Printing Solutions (B3DPS) will be exhibiting at Formnext 2019 sector show for additive-based manufacturing, with an expanded product range and a new brand presence. Sector specialists are invited to meet B3DPS specialists in person from November 19 through 22 at Booth D21, Hall 12.1 at the Frankfurt Trade Fair. With the introduction of its new Forward AM corporate brand, B3DPS continues to pursue its goal of driving industrial scalability as the next phase of additive-based manufacturing, the company says. “Forward” stands for future-oriented, leading-edge materials and technology, while “AM” stands for “additive manufacturing”. The new arrow-symbol brand logo…

Found in Robotics News & Content, with a score of 33.23

MakerBot, a Stratasys company, reports that the BASF Ultrafuse 316L Stainless Steel material by Forward AM has been qualified for the MakerBot LABS Experimental Extruder for the MakerBot METHOD 3D printers. With an open materials platform and a portfolio of advanced engineering-grade materials, METHOD is an industrial desktop 3D printer with a heated chamber that can print polymer, composite and metal materials. Ultrafuse 316L Stainless Steel material combines strength, rigidity and durability needed for applications including functional prototypes and manufacturing tools. Available using the MakerBot LABS GEN 2 Experimental Extruder, this metal-polymer composite material provides METHOD users with an option…

Found in Robotics News & Content, with a score of 33.00

…debuted a certified thermoplastic polyurethane (TPU), ULTRASINT, developed by BASF, to expand final-parts applications for the new Jet Fusion 5200 Series systems. The new TPU is made for flexible and elastic parts and complements HP High Reusability PA-12, PA-12 Glass Beads and PA-11 materials, HP reports. Already, BASF and HP are working with Sculpteo, a provider of 3D design and production services, on new applications produced with BASF’s ULTRASINT TPU on HP Jet Fusion 3D printing systems. The new TPU material ULTRASINT was developed by BASF, to expand final-parts applications for the new Jet Fusion 5200 Series systems. It can…

Found in Robotics News & Content, with a score of 31.61

…printing system, the CBAM-2, and a new partnership with BASF on PA6-carbon fiber composites extend Impossible Objects’ composite based additive manufacturing process (CBAM) to a range of industrial applications. “It’s been exciting to see how our customers are putting our approach to work to create high-performance parts for everything from aircraft and cars to lightweight athletic gear,” says Impossible Objects founder and chairman Bob Swartz. “We’re continuing to bring machines, materials and expertise to the market to transform the entire manufacturing process, from prototyping through to high-volume production.” CBAM-2 Speeds Production of 3D Parts at Scale The new CBAM-2 3D…

Found in Robotics News & Content, with a score of 30.35

…solution for production 3D manufacturing. The printing system counts BASF, Materialise and Siemens as strategic partners, creating what HP calls “a new global community of proven large-scale 3D printed parts providers.” The printer is the latest refinement of HP’s work in Multi Jet Fusion (MJF) printing technology, which prints on a line-by-line basis. HP says the method is inspired by its long history of 2D wide format printing, but relies on a variety of innovations for 3D. HP says MJF allows for faster cooling and increased automation of post-processing compared to selective laser sintering (SLS). MJF allows almost 90% of…

Found in Robotics News & Content, with a score of 25.50

…The new HP 3D High Reusability PP, enabled by BASF, is a durable and chemically resistant material that has been qualified for HP’s production-grade 3D printing systems, and is ideal for customers in the automotive, consumer, industrial and medical sectors. HP also unveiled a new partnership with Oechsler, a global design and manufacturing player, to develop applications for both the new PP and HP’s broader materials portfolio, as well as new customer Cobra Golf for its Metal Jet 3D printing technology. Door defroster vent used in the ventilation system of automobiles. Printed with HP 3D HighReusability PP enabled by BASF.…

Found in Robotics News & Content, with a score of 17.53

…demand,” says Firat Hizal, head of Metal Systems Group, BASF 3D Printing Solutions. “We have already established a distribution network that collaborates closely with our debinding and sintering service partners in different regions, and can thus deliver an integrated end-to-end solution,” explains Hizal. Ultrafuse metal filaments are specifically developed to work on all common open-source FFF printers from beginner to industrial level, making it one of the easiest and most cost-effective technologies in metal Additive Manufacturing. FFF enables the production of hollow structures and lightweight designs. Additionally, users benefit from the traditional advantages of a non-oxidizing metal, such as corrosion…

Found in Robotics News & Content, with a score of 16.18

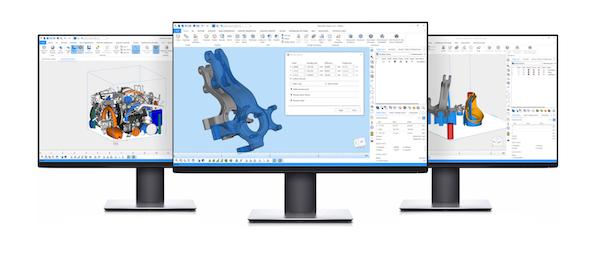

…starts, all the way back to design.” Materialise and BASF jointly conducted a lifecycle analysis of insole manufacturing, comparing traditional and contemporary additive manufacturing processes. The results showed AM lags behind traditional methods for sustainability. Image courtesy of Materialise. Materialise and BASF conducted a Lifecycle Analysis (LCA) recently to get a closer look at sustainability in additive manufacturing. They studied the production of one million pairs of midsoles, assessing the environmental impact in all stages of the product life. They compared the environmental impact of three 3D printing technologies with a conventional manufacturing technology: polyurethane casting. The LCA indicates that…