Editors’ Picks

Found in Robotics News & Content, with a score of 46.33

Applied Automation Technologies (AAT) and DMG MORI have set up a partnership for on-machine measuring software. The companies will offer this software technology as a solution within the DMG MORI Qualified Products (DMQP) program. Having the ability to perform CMM (coordinate measurement machine) measurement and metrology tasks is an important part of ‘smart machining’ manufacturing processes. CappsNC provides capabilities to quickly develop measurement programs offline and run these programs directly on CNC machine tools in a similar way to a CMM. Measurement results are used to adjust machining process parameters such as calculating precise work offsets, dynamic tool compensations and…

Found in Robotics News & Content, with a score of 39.16

Applied Manufacturing Technologies, or AMT, today announced that it has opened a second factory near its headquarters in Orion, Mich. It said the new facility will “empower collaboration and industry innovations” for its industrial automation and robotics customers. “Thanks to a year of unprecedented growth, AMT has had the opportunity to invest in our future by nearly doubling our production area,” said Michael Jacobs, founder and CEO of Applied Manufacturing Technologies. “We have thoughtfully designed the new facility at 250 Kay Industrial Drive to complement the existing production capabilities at our headquarters, allowing us to better meet the needs of…

Found in Robotics News & Content, with a score of 38.17

Applied Manufacturing Technologies, an automation engineering company supporting manufacturers, robot companies, systems integrators, line builders, and automation users worldwide, today announced a strategic partnership with robotic tooling and software manufacturer Soft Robotics Inc. “We have seen a sharp uptick in requests to provide specialized material handling solutions for a variety of industries,” stated Rick Vanden Boom, vice president of sales at Applied Manufacturing Technologies (AMT). “We are excited to partner with Soft Robotics as a preferred system integrator to best take advantage of their unique gripping technologies and software.” Founded in 1989, Applied Manufacturing Technologies said it has more than…

Found in Robotics News & Content, with a score of 37.25

Automation systems integrator Applied Manufacturing Technologies this week announced it will unveil its new robotic decanting technology it developed in partnership with 3D machine vision automation company Liberty Reach at the Automate 2022 trade show next month. Using a FANUC CRX-10iA collaborative robot and Schmalz FXCB vacuum gripping system, the Orion, Mich.-based company’s robotic cell will show solution planning for de-layering and tote filling. It uses defined box and tote parameters to optimize the tote fill and solve the entire layer. The Schmalz FXCB gripping system integrates a vacuum generator, flow resistors, and digital pressure switch into a compact and…

Found in Robotics News & Content, with a score of 35.95

Applied Manufacturing Technologies, or AMT, last week announced the details of its planned presentations at Automate 2022 in Detroit and its collaboration with Liberty Reach Inc. “Applied Manufacturing Technologies will have an extensive presence at Automate 2022,” said Rick VandenBoom, vice president of sales at AMT. “Not only are we presenting two of-the-moment technical seminars at our booth, but we will also be showcasing groundbreaking robotic and AI technology for mixed-case palletizing/depalletizing/decanting of multiple cases using optimized best-fit finding algorithms.” AMT to present two sessions Terry Meister, controls manager at Applied Manufacturing Technologies, will present “Autonomous Mobile Robots—Integrator’s Insights on…

Found in Robotics News & Content, with a score of 29.48

Conveyco Technologies (Booth 1614) is showcasing its new Proof of Concept (POC) program for autonomous mobile robots (AMRs). The new program allows organizations to conceptualize, emulate and validate AMR system’s performance prior to financially committing to an entire system. “Organizations are seeing the results AMRs can deliver. However, they are overwhelmed by the sheer amount of options that are available and where this technology can be applied within their operations,” said Ray Cocozza, president. “The Conveyco AMR POC Program is designed to address this fear by providing a scalable approach to select the best technology and tune the concept before…

Found in Robotics News & Content, with a score of 28.86

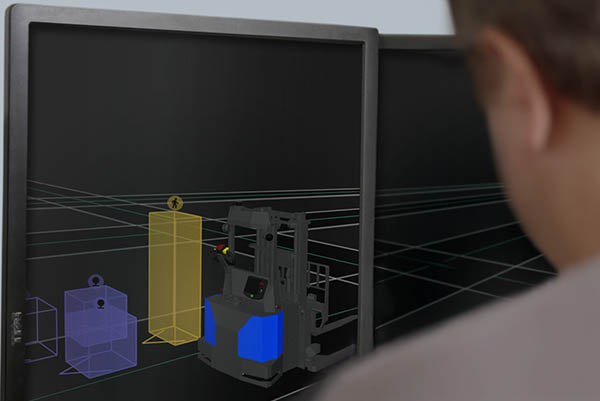

…Seegrid Corp. today announced that it has partnered with Applied Intuition Inc. to create 3D virtual warehouses, factories, and distribution centers to support the acceleration of material handling automation. “Consumer demand and a shrinking labor force are putting pressure on nearly every industry, and in turn, putting pressure on AMRs [autonomous mobile robots] to effectively and consistently interpret and respond to ever-changing situations,” said Jim Rock, CEO of Seegrid. “Our customers rely on Seegrid to deliver industry leading automation solutions that can safely ensure productivity—highly advanced simulation during ideation, test, and development speeds up our ability to deliver next-generation AMRs…

Found in Robotics News & Content, with a score of 27.57

…Inc.; Mark Lewandowski, Procter & Gamble; Bob Little, ATI Industrial Automation; John Lizzi, General Electric; Tyler McCoy, JR Automation Technologies LLC; Gary McMurray, Georgia Institute of Technology; Craig Salvalaggio, Applied Manufacturing Technologies; Walter Vahey, Teradyne; and Carol Woten, Genesis Systems - IPG Photonics Company. After many years of dedicated service, Catherine Morris, ATI Industrial Automation; Stu Shepherd, Universal Robots; and Mike Jacobs, Applied Manufacturing Technologies are departing the RIA Board. These three board members were recognized at the recent A3 Business Forum for their service to the industry and to the RIA and A3 associations.

Found in Robotics News & Content, with a score of 21.48

…Robots A/S has granted UR+ partner certification to its Applied Cobotics Cobot Feeder, an application kit that delivers and stages parts to be placed into a CNC machining process. “Machine tending is a critical process in manufacturing and one of the most popular applications for UR cobots,” said Joe Campbell, senior manager of applications development at collaborative robotics leader Universal Robots, in a press release. “By constantly feeding the cobot new parts to accurately pick and place, Applied Cobotics optimizes this process significantly,” he added. “We’re excited to include the Cobot Feeder in the UR+ product portfolio, benefitting our rapidly…

Found in Robotics News & Content, with a score of 21.06

3D Systems has been selected by Raytheon Technologies and the Combat Capabilities Development Command (DEVCOM) Army Research Laboratory (ARL) as part of a research project titled “Research for Virtual Design and Qualification Process for Additively Manufactured Parts Optimized for Multi-Laser Machines” awarded through the National Center for Manufacturing Sciences’ (NCMS) Advanced Manufacturing, Materials, and Processes (AMMP) program. Working in conjunction with Raytheon Technologies, the Penn State Applied Research Lab, Johns Hopkins University and Identify3D, the goal is to optimize a component relative to an Army modernization product to maximize cooling and improve overall system performance. Using additive manufacturing (AM) to…

Found in Robotics News & Content, with a score of 20.74

VELO3D Inc., which specializes in additive manufacturing for metal parts, today said that Vertex Manufacturing, a provider of CNC machining and manufacturing services from development through production, has chosen it to help meet growing demand for 3D-printed “impossible” metal parts. “At VELO3D, we help innovators like Vertex accelerate the future of manufacturing, not just for their customers, but to benefit all of humanity,” stated Benny Buller, founder and CEO of VELO3D. “This new partnership speaks to the real and transformational capabilities VELO3D is bringing to metal additive manufacturing.” Founded in 2014, VELO3D offers fully integrated, patented systems including the Flow…

Found in Robotics News & Content, with a score of 20.67

…defect detection solution to accelerate AI development for advanced manufacturing and warehouse robotics applications. iMerit's defect detection application enables AI development teams to build high-precision machine learning models for fully-automated production lines on the manufacturing floor. The solution can be fully customized to streamline defect detection on material surfaces in manufacturing environments, enabling companies to tailor it to their specific factory needs. The new purpose-built application is fully integrated with iMerit's Ango Hub, an end-to-end enterprise-grade technology platform that enables AI teams to quickly and efficiently build scalable data pipelines and provide the building blocks for custom solutions. “AI is…