Editors’ Picks

Found in Robotics News & Content, with a score of 1.44

…and ABB says the robots are known for their ease of use, safety and precision. It incorporates a range of features that allow it to be used safely, directly alongside human workers and without the need to design and build bulky barriers or fencing. GoFa can continuously share workspace with people, giving it maximum flexibility and efficiency. By equipping MassRobotics with its advanced cobots, ABB intends to facilitate the creation of new and impactful offerings that address real-world challenges across various industries. This initiative also aligns with ABB’s broader strategy to support technological advancement and foster collaborations that drive sustainable…

Found in Robotics News & Content, with a score of 1.23

…tools to their students. Our accessible price point and ease of use will enable more educators to offer the valuable hands-on experiences so critical to success in today’s manufacturing environments.” At a base price of $5,000, educators can now afford to provide a low student-to-equipment ratio so each student can spend more time directly working with the robots. This interactive learning approach not only increases knowledge retention in areas such as mechatronics and programming but also provides a comprehensive view of robotic systems. This prepares students of all levels for real-world application environments while sparking their interest in the field.…

Found in Robotics News & Content, with a score of 0.97

When Universal Robots (UR) recently surveyed 1,200 manufacturers across North America and Europe about their use of technology and future investment plans, over 50% of the respondents indicated they are now using AI and machine learning in their production processes. At IMTS 2024, UR showed a machine-tending application with new AI-based perception capabilities running on NVIDIA Jetson and Isaac acceleration libraries integrated into UR’s new PolyScope X platform. This combination enables dynamic path planning, ensuring the robot takes the most effective, collision-free paths in and out of the machine without requiring extensive user configuration. UR plans to make this technology…

Found in Robotics White Papers & Archives, with a score of 3.00

…Once that is complete, the AMRs are designed for ease of use by your operational team. No more training is needed than for any other new technology addition, and you do not need a team of robotics engineers on staff. 3. AMRs are too expensive When you look at an AMR it’s easy to jump to the conclusion that they are too expensive for the average warehouse. They seem like a futuristic technology decades in the making, and an investment that only top-tier warehouses can afford. In reality, many AMR solutions are affordable for any size warehouse. Many of the…

Found in Robotics News & Content, with a score of 0.91

…processes has allowed Greenzie to focus more on innovation and less on solving technical issues. The tool's extensibility and ease of use have fostered a proactive approach to product improvement and customer service, which Foxglove said ultimately enhances Greenzie's market position in autonomous outdoor lawn care equipment. “Thanks to Foxglove we're no longer spending time fighting with tooling - we're developing revenue-generating product and helping our customers, which is why we exist,” Quinn said. Want to learn more about data management in robots? This article was featured in the September 2024 Robotics 24/7 Special Focus Issue titled “Robots as mobile…

Found in Robotics News & Content, with a score of 0.58

…applications in manufacturing as well. I think because of ease of use and a specific lack of people to do certain tasks, you're going to see continued growth in manufacturing. On the collaborative front, one of our conversations at Automate went into how cobots right now are in the “Wild West” because there isn’t an industry standard for what makes a “collaborative” robot. What are your thoughts on the definition of collaborative robots and how cobots are involved in the robotics industry? Burnstein: I suppose we can call it more of collaborative applications. There's no such thing as a collaborative…

Found in Robotics News & Content, with a score of 0.83

Comau started offering industrial automation solutions over 50 years ago for many of the world’s biggest car manufacturers. As automation technology has changed over the years, so has its reach. Today, Comau is applying its field-proven experience and process expertise to meet the rising demand for automation in diversified industries such as warehousing and logistics, food and beverages, pharmaceuticals, renewable energy and other sectors looking to increase quality and efficiency with tailored automation solutions. The global technology company has returned to Automate 2024 in Chicago to showcase its portfolio of sustainable, advanced automation robotic offerings that drive the “Power of…

Found in Robotics News & Content, with a score of 1.65

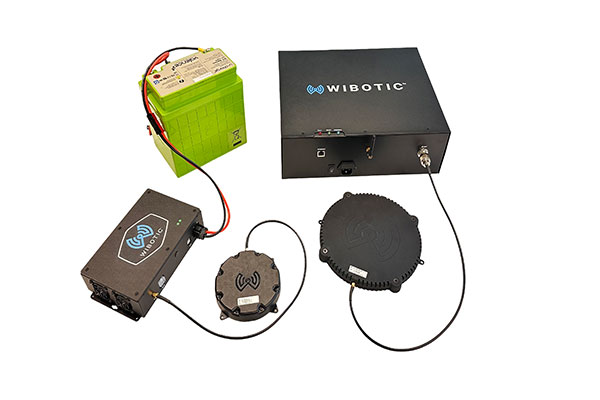

…request we get from our customers, and we’ve been working to develop a new product that provides the same ease of use and reliability as our field-proven lower power systems.” said Ben Waters, CEO of WiBotic. “The new system is interoperable with all existing WiBotic hardware and is fully programmable using our software, APIs and the Commander platform for larger fleets.” Automate Show attendees can experience a demonstration of the 1kW system at Booth #4087 near the ARM Demo Area. WiBotic is accepting advance orders for its 1kW system, with delivery scheduled for this summer.

Found in Robotics News & Content, with a score of 1.53

…Longmont, CO. Source: Scythe Robotics Production line designed for ease of use, minimized waste In the design of the production line, Scythe implemented a unidirectional movement system that empowers the manufacturing team to monitor progress visually, minimize waste, and operate at peak efficiency. The design ensures that each M.52 unit meets quality standards and delivery schedules. “Ensuring a quality product that is delivered in a timely manner hinges on our ability to proactively optimize workflows throughout the manufacturing process,” said Kip Atkinson, senior manufacturing engineer at Scythe. “Through the adoption of lean manufacturing principles, we swiftly pinpoint and rectify any…

Found in Robotics News & Content, with a score of 1.60

…warehouse drawings modified in real-time will demonstrate the software’s ease of use for logistics professionals. Armor PowerFlex Drives: Get access to updated Armor PowerFlex distributed control solutions that simplify design, integration and maintenance through on-machine motor control. Attendees will discover how these scalable solutions prioritize safety and durability in material handling environments. Interactive Virtual Warehouse: Explore videos and demos of the latest warehouse and logistics solutions - like independent cart technology, digital facility design, unified robotic control and more. Attendees can connect with industry experts to discuss how these solutions can optimize their unique warehousing configuration. OTTO Motors with Rockwell…

Found in Robotics News & Content, with a score of 1.92

…technologies, their transition can ensure lower charging costs, greater ease of use, and expanded access to charging facilities for landscape companies. The next generation of Scythe’s M.52, slated for production in late 2024, will integrate NACS components as they are made available for non-Tesla, Inc. manufacturers. “By incorporating NACS into the next generation of our machine, M.52 will potentially be the first non-Tesla vehicle to implement this new standard,” said Roger Dodrill, staff systems engineer at Scythe. “By providing the gold standard in charging capabilities, we aim to eliminate barriers to the adoption of electric equipment and enhance the overall…

Found in Robotics News & Content, with a score of 1.94

ABB Robotics and METTLER TOLEDO, a global supplier of precision instruments and services, have signed a Memorandum of Understanding (MOU) to offer a solution to integrate ABB robots with LabX, METTLER TOLEDO’s laboratory instrument management software. The combined solution will enable greater levels of efficient and high-quality automated laboratory workflows across a range of industries, making research, testing and quality control more flexible, while accelerating time-to-market and addressing critical labor shortages. Partnership focuses on expediting tasks, limiting human errors With the collaboration, METTLER TOLEDO’s LabX software will integrate into ABB’s OmniCore robot controllers, enabling LabX to orchestrate robotic lab workflows.…