Editors’ Picks

Found in Robotics News & Content, with a score of 45.17

…Electric’s low-cost robot series. Built in cabling for flexible EOAT options Built-in features help provide enhanced safety, streamlined implementation, and an overall reduction in downtime. The RV-12CRL includes internal cables and air hoses for end-of-arm tooling (EOAT), including 30 pins of signal cabling. Mitsubishi Electric has eliminated the need for encoder batteries that may cause tedious, expensive maintenance by adding MELSERVO-J5 servo motors, known for their battery-less encoder nature. Mitsubishi Electric said safety is a forethought, not an afterthought, with this robot launch through added safety via its CR800 controller to support safety monitoring functionality. The RV-12CRL series of robots…

Found in Robotics News & Content, with a score of 17.46

…gain that performance back.” Automated flexibility thanks to interchangeable EOAT Interchangeable end-of-arm tooling (EOAT) has provided Rethink’s new robot arms with operational flexibility that was lacking with its original robots. “Baxter and Sawyer had cameras embedded in the arms,” Harbert said. “There was an ease because it came with a camera. The challenge, of course, was that it wasn't always the right camera for what you wanted the robot to do. “The original Rethink had their own grippers that they designed and fabricated,” he added. “That's fine for some applications, but there were limitations in terms of the connectivity with…

Found in Robotics News & Content, with a score of 8.91

…as grippers, vision systems, rails, and other end-of-arm tooling (EOAT) and peripheral tools. At IMTS 2024, Rethink unveiled the robots and showcased integration for machine tending, palletizing, and bin picking. Riser mobile manipulation robot combines Reacher and Ryder Rethink said its Riser MMR can allow a single AMR to serve multiple stationary cobot applications. The robot combines a Ryder AMR with a Reacher cobot and an independent, detachable battery box. Rethink said the combined MMR can allow mobile manipulation to be performed at new levels of efficiency. Reacher and Ryder each have their own battery packs, requiring separate charging. Reacher…

Found in Robotics News & Content, with a score of 8.78

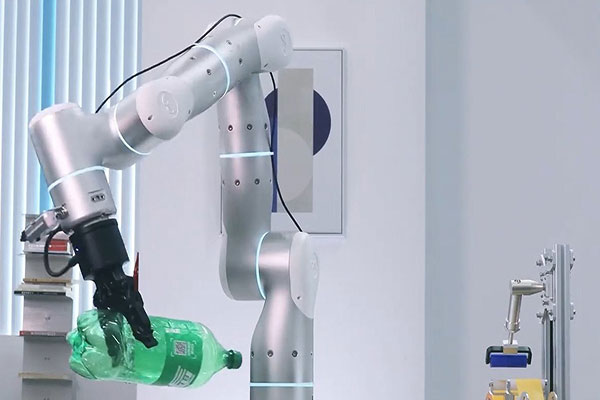

…Robotics The end result is end of arm tooling (EOAT) combined with a software platform that can identify and grasp objects to within a few millimeters. That capability creates the high level of precision required to work in a variety of environments, including a current Rapid customer that handles stuffed animals. “The grippers usually only have to handle 10 or less things,” Hummel said. “It basically means that we can really tune the gripper in a reasonable amount of time, like a week or two, to do that task very successfully.” Whether RapidID is grasping stuffed animals, cans, embalming fluid…

Found in Robotics News & Content, with a score of 9.36

…motors drive the swivel units that move end-of-arm tooling (EOAT) or components to specific positions. When selecting a suitable drive, an important factor for STIWA engineers was the availability of an accessory part. “At this point in the system, we require an extremely high level of precision and repeatability,” Mersnik said. “This is why it was an important argument for us that Faulhaber was able to deliver this motor with a matching multiturn absolute encoder. The signals from this encoder are necessary to achieve the high production quality and for quality assurance.” At least 60 million fault-free strokes guaranteed by…

Found in Robotics News & Content, with a score of 10.86

…tending OnRobot said a stronger end-effector, or end-of-arm tooling (EOAT) platform for industrial robots deployed in collaborative applications enables improved workpiece adaptability. The company’s new grippers offer an all-round plug and produce experience, including fingers with multiple configurations, flange adapters, cabling, and software that removes complexity of robot programming, said OnRobot. “As cobots grow more powerful, OnRobot customers are scaling up their collaborative applications,” says Enrico Iversen, OnRobot CEO. “Building on the success of our existing, industry-proven gripper range, the new 3FG25 and 2FG14 grippers deliver unrivaled gripping and payload power while also providing customizability for heavy-duty applications, including harsh…

Found in Robotics News & Content, with a score of 12.94

…to be integrated between robot arms and end-of-arm tooling (EOAT), maintaining the integrity of internal cable routing. Bota said many robotic arm manufacturers are moving towards internal routing to eliminate cable tangles and motion restrictions. Bota offers a uniform interface across all models to facilitate integration. Its design minimizes external connections and component count, significantly enhancing system reliability. “Our objective is to equip robots with the sense of touch, making them not only safer and more user-friendly, but also more collaborative,” said Klajd Lika, Bota CEO and co-founder. “PixONE is an advanced, OEM-ready sensing solution that enables robot developers and…

Found in Robotics News & Content, with a score of 9.44

…the need for pneumatic vacuum pumps and end-of-arm tool (EOAT) changes. Automated Cleaning Station doesn’t require proprietary equipment Flexiv said it has improved its Grav Enhanced gripper so that it can now be cleaned using its Grav Enhanced Automated Cleaning Station. The cleaning station allows Rizon to operate effectively in environments where exposure to particulates could diminish the gripper's lifting efficiency, including manipulating objects covered with surface contaminants like dirt and dust. Flexiv’s new Automated Cleaning Station uses standard adhesive tape and a silicone roller to clean the Grav Enhanced gripper’s super friction material. Source: Flexiv Robotics “By packaging the…

Found in Robotics News & Content, with a score of 5.42

…to 200-400 millimeters per second depending on end-of-arm tooling (EOAT) and size of product being handled. Further zones are commonly set at 400-1000 millimeters per second. On the end of its cobot arms, Yaskawa installed an indicator light that turns green when the robot is operating in collaborative mode - meaning humans can safely approach it - and turns off when the robot operates in industrial mode. Minimizing footprint while maximizing workflow One challenge manufacturing and logistics warehouses must consider is how to accommodate the footprint of robotic workcells. The goal is to limit how much floor space each robot…

Found in Robotics News & Content, with a score of 13.63

…but also eliminates the need for specialized end-of-arm tooling (EOAT) and force sensing during sanding tasks.” An EsVata staff member operates Flexiv’s Rizon 4 adaptive robot arm with an OnRobot sander attached to the universal mounting flange. Source: Flexiv Robotics By automating sanding, EsVata’s employees are now freed from monotonous, labor-intensive sanding tasks, which enables them to engage in more valuable roles within the company. Flexiv said this reallocation of human resources underscores EsVata’s commitment to enhancing employee satisfaction, and highlights its belief in enhancing the impact of human labor through collaborative robotics rather than replacing it. Customized interface, universal…

Found in Robotics News & Content, with a score of 13.99

…the intelligence to choose and select different end-of-arm tools (EOAT), and then ascertain the precise grasp pose to avoid interfering with adjacent cases. “Depal is a warehouse workflow characterized by heavy use of manual labor and high levels of workplace injuries,” said Motohiro Kawada, CEO of IHI. “Addressing this challenge aligns closely with our corporate mission of designing and building progressive engineering solutions for people and the planet… Our decision to move forward with OSARO is based on their ability to handle a wider variety of boxes at much faster recognition speeds than other vendors.” OSARO’s Sightworks machine-learning software maximizes…

Found in Robotics News & Content, with a score of 49.20

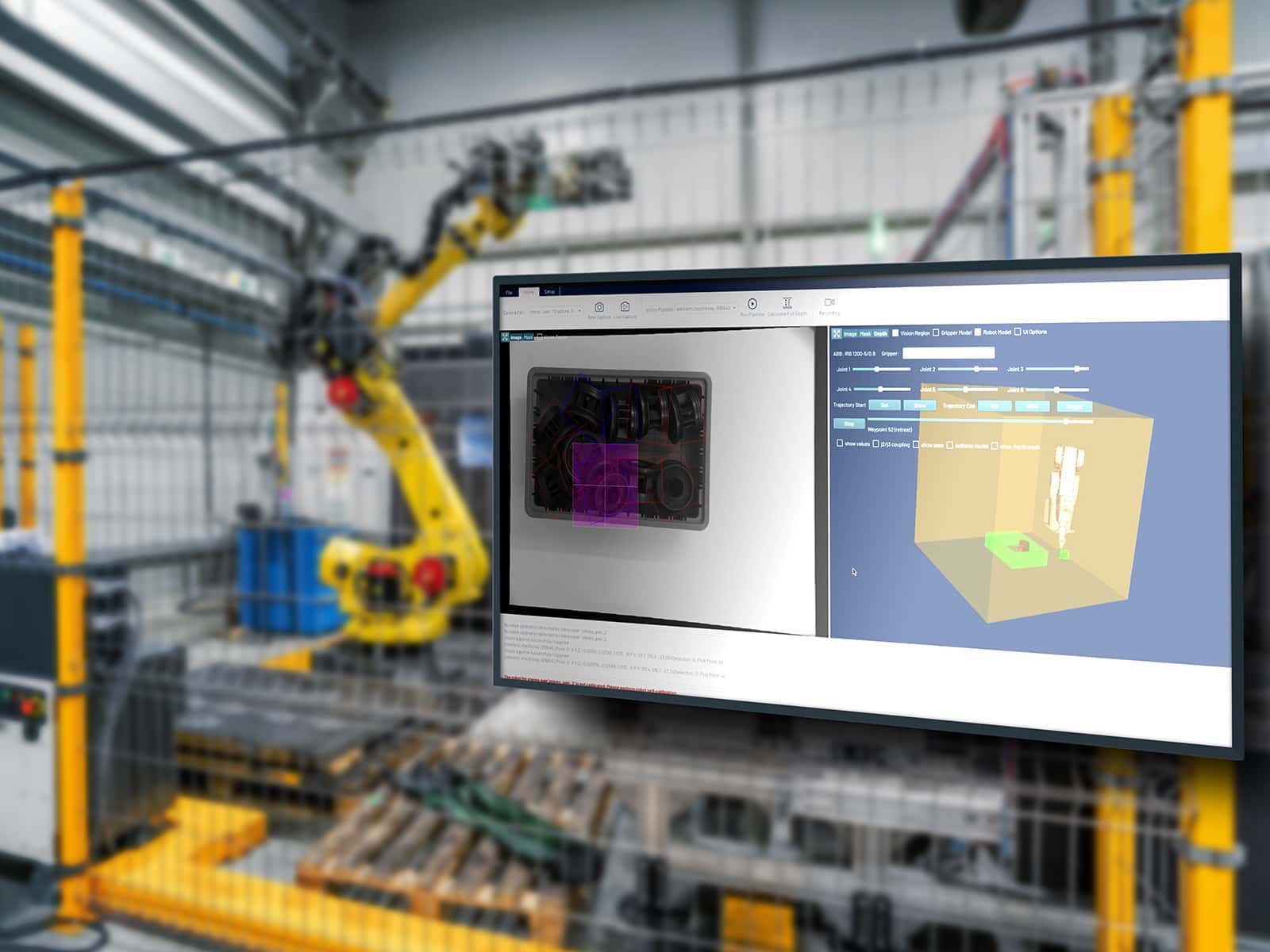

…to part orientation. Customers report that custom end-of-arm tooling (EOAT) can be a challenge to the performance of a vision-guided cell. In Vue, you can upload a CAD model of the EOAT and achieve excellent EOAT to object orientation. That matters a lot in assembly or material handling applications where a part must be precisely placed for the next step of manufacturing. Apera’s Tier 1 automotive customers report significant advantages with this feature, including the ability to pair robots together more reliably, which helps lower the risk of custom EOATs. Watch this video to learn more about how AI-powered vision…