Editors’ Picks

Found in Robotics News & Content, with a score of 13.11

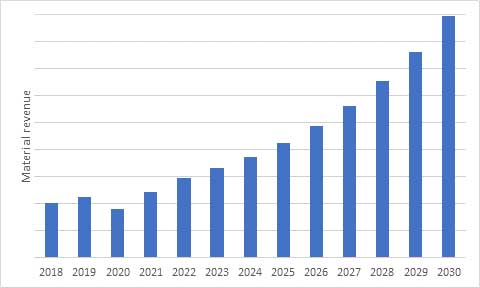

3D printing offers a means to improve current manufacturing limits across economic sectors such as transport, construction, and medical and dental industries allowing rapid prototyping and on-site production and repairs, according to IDTechEx. Progress in 3D printer development has led to faster, larger and more accurate printers, but these require more functional materials, IDTechEx adds. The company has released a new report, “3D Printed Materials Market 2020-2030: COVID Edition.” 3D printing use in the medical industry is restricted by the lack of biocompatible and biodegradable materials suitable for the 3D printing of medical devices with silicone-like mechanical properties. Korean researchers…

Found in Robotics News & Content, with a score of 16.78

…BEE cage is designed to challenge the limits of additive manufacturing, company says. The honeycomb endplate design reduces the risk of subsidence while allowing fusion. The honeycomb structure allows for bony ingrowth and demonstrates the reduced use of titanium minimizing risks of X-ray artefacts, while offering a very large graft space. This is another innovation from the team, who invented the first line of additively manufactured interbody devices. “This is an important step for NGMedical and allows us to start our active market presence in the USA. We are proud having received the FDA clearance based on the innovative design…

Found in Robotics News & Content, with a score of 19.87

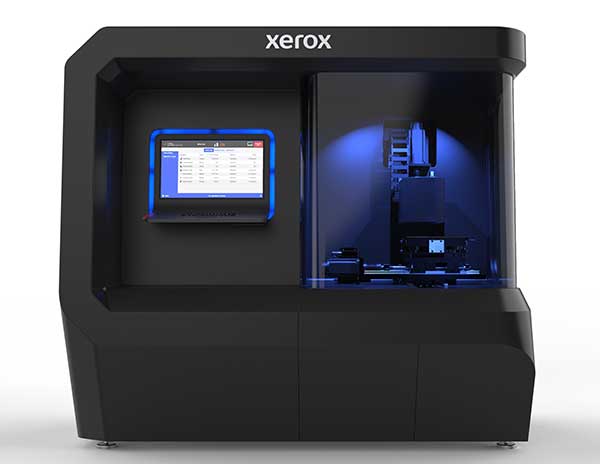

…School (NPS) announces a strategic collaboration focused on advancing additive manufacturing research, specifically 3D printing, which has the potential to transform the way the military supplies its forward-deployed forces, organizations note. As part of a Collaborative Research and Development Agreement (CRADA), NPS was the first to receive an installation of the Xerox ElemX Liquid Metal Printer on the university campus in December. The Xerox solution will provide NPS faculty and students with hands-on exploration of new ways the technology can deliver on-demand 3D printing of metal parts and equipment. “The military supply chain is among the most complex in the…

Found in Robotics News & Content, with a score of 16.35

…in low volumes for pre-production and end-use applications. “As additive manufacturing adoption advances worldwide, Desktop Metal continues to drive innovations that enable the technology to more effectively compete with conventional manufacturing processes,” says Ric Fulop, CEO and co-founder of Desktop Metal. “Our next-generation Studio System 2 takes the best features of the original Studio System+ and significantly improves upon them, delivering higher quality end-use metal parts through a more streamlined and accessible process, and within an even smaller footprint.” Enhancements include new print profiles and an all-new material system designed to deliver part quality, accuracy and surface finish while minimizing…

Found in Robotics News & Content, with a score of 39.39

…over the last year showed 3D printing's relevance in manufacturing, according to Essentium. The AM industry stepped in to make quantities of supplies at scale to keep assembly lines moving. 2021, adds to Essentium, will mark the year that additive at scale transforms manufacturing across sectors, including aerospace, automotive, electronics manufacturing services and biomedical. Specifically, 98% of manufacturing executives see value in improved materials, 37% are limited by the high cost of 3D printing materials, and 24% said 3D printing materials are unreliable. Gaining approvals for capital investments will remain a challenge throughout 2021; 20% of executives report that industrial-scale…

Found in Robotics News & Content, with a score of 15.81

…manufacturers at all levels to rethink product development, hybrid manufacturing and end-use production, company says. Additionally, the company launched Fuse Sift, a post-processing system for the Fuse 1, and Nylon 12 Powder, Formlabs’ first powder material for Fuse 1, to provide users with an end-to-end SLS workflow. The Fuse 1 and Fuse Sift improve on the advantages offered by SLS, while bringing it within reach for companies of all sizes and types through affordability and ease of use, company says. “The Form 1 redefined stereolithography (SLA) printing for the additive manufacturing industry 10 years ago, and now the Fuse 1…

Found in Robotics News & Content, with a score of 12.77

e-Xstream engineering, part of Hexagon’s Manufacturing Intelligence division, has introduced simulation and virtual manufacturing capabilities that enable users to analyze the production cost of polymer-based additive manufacturing parts against conventional processes, and continuously improve virtual engineering processes by validating the composite’s microstructure with computing tomography scans of manufactured parts. The latest Digimat software enables businesses to simulate the 3D printing process and calculate the total cost of producing each part including the material use, employee time, energy and required post-processing steps. Using this new tool, an engineer can take a holistic view of part production and finishing processes to determine…

Found in Robotics News & Content, with a score of 18.36

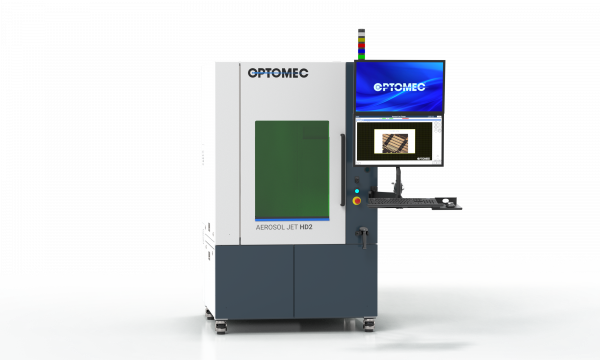

…various materials including common polymers, IC materials, FR4, glass, ceramic and metals. The HD2 was designed for high volume manufacturing and includes production-friendly software that guides operators through a simplified start-up process, ensuring QA compliance. The machine is also available with an in-line conveying option for automated part loading. It can process substrates or part trays up to 300-mm wide and is available with a rotate table for four-axis processing.

Found in Robotics News & Content, with a score of 12.61

…quality prints at high volumes, making it an ideal additive manufacturing partner for the dental industry,” says Keystone Dental President Ira Rosenau. Nexa3D’s NXE 400 3D printer features LSPc technology that combines build volume, print uniformity, advanced process algorithms, modular design for onsite automation and intelligent optimization, the company says. Offering a 16-liter build volume and productivity gains, the NXE 400 printer yields part-throughput gains while offering low cost of ownership in its class on the market, the company says. Nexa3D enters the dental market with all of Keystone’s KeyPrint resins, including KeySplint Soft, a material that delivers a combination…

Found in Robotics News & Content, with a score of 30.87

…the EnvisionTEC team to bring significant growth to the additive market,” says Ric Fulop, founder and chief executive officer of Desktop Metal. “EnvisionTEC is a true pioneer and responsible for many of the leading technologies widely used today to produce end-use photopolymer parts through additive manufacturing. Together, Desktop Metal and EnvisionTEC have an opportunity to shape the future of Additive Manufacturing 2.0 and transform how parts are made around the world.” EnvisionTEC D4K Pro 3D printer. Image courtesy of EnvisionTEC. “I am excited and honored to partner with Ric and the Desktop Metal team to deliver end-use parts in both…

Found in Robotics News & Content, with a score of 37.19

…has introduced Onyx ESD, a new composite material for additive manufacturing of electronics. The company, a builder of additive manufacturing equipment, says the new material is a high-performance static-dissipative version of its popular Onyx, a micro carbon fiber-filled nylon. Markforged says electronics manufacturers have not been able to innovate with additive manufacturing due to the lack of static-dissipation materials. Electronics manufacturers must use materials that meet electrostatic discharge (ESD) safety requirements, to avoid damaging a product or critical component during production. Though there are other ESD-safe materials in the market, Markforged’s is reportedly the only to offer the highest strength…

Found in Robotics News & Content, with a score of 31.14

…the last 5 years, Infocus has focused on the additive manufacturing (AM) market and has successfully developed metal AM markets in aerospace & defense, universities and R&D, oil & gas/energy, medical and automotive industries. The addition of SPEE3D technology now means they can offer clients expertise in cold spray additive manufacturing (CSAM). Infocus will provide the technical sales and after-sales service including installation, training and day-to-day support of SPEE3D machines. Infocus is led by Welodimer Neustadter Jr. As a technology enthusiast with extensive experience and training in Metal AM, Welodimer’s goal is to supporting AM businesses in Brazil. “SPEE3D’s metal…