Editors’ Picks

Found in Robotics News & Content, with a score of 14.90

…the facility on air shipment pallets or as parcel deliveries from FedEx or UPS. Deliveries are received by purchase order and reconciled for quantity and quality (not shown). Once a delivery has been inspected it is entered into the warehouse management system (WMS), and labeled with a license plate bar code label that represents the quantity and SKU. Product ready for storage is then put onto a rack and staged for putaway. Putaway: Putaway is directed by the WMS. In the area enabled by mobile robotics (1), a tote with items ready for storage is scanned onto one of the…

Found in Robotics News & Content, with a score of 7.28

…of optimization in manufacturing, logistics, warehousing and last mile delivery that could become a reality in less than half a decade despite high set-up costs deterring early adoption in logistics. Changing consumer behavior and the desire for personalization are behind two other top trends Batch Size One and On-demand Delivery: Set to have a big impact on logistics, on-demand delivery will enable consumers to have their purchases delivered where and when they need them by using flexible courier services. Batch Size One explores what could happen as consumer demand for highly personalized products goes head to head with mass production…

Found in Robotics News & Content, with a score of 3.03

…continuous pressure from customers to keep costs low and delivery turnaround fast. So what are we to make of all this attention on robots at Modex? Are we at the crest of the usual hype cycle, focusing on robots because they are fun to talk and write about, but not likely to see much use anytime soon? I believe serious uptake for robots will happen rapidly in DCs, mainly because of the increasing labor pinch. As one keynote panelist, Todd Farwell, global resource deployment champion with Caterpillar, put it, simply adding more human labor to mounting operational pressures won’t cut…

Found in Robotics News & Content, with a score of 5.69

…began to ask how it could speed up the delivery of a new pair of glasses to its customers, says Joe Maris, the senior vice president of lab operations for VSP Optics Group. The answer was a $37 million investment in an 80,000-square-foot, state-of-the art production lab in Folsom, Calif., that doubles the footprint of the original location and is designed to improve the speed to market. The lab has 401 employees and processes nearly 6,000 pairs of eyewear each day with plans to expand to 8,000 pairs of eyewear daily in the coming years. According to Maris, it features…

Found in Robotics News & Content, with a score of 4.24

…will know the machine inside and out prior to delivery.” Training courses include: Robotic training cell 1. Introduction to Schneider robotics 2. General FANUC robotics 3. Unit load creation using Pallet Pro and/or Schneider pallet generation software 4. Robot troubleshooting Programmable logic controllers (PLCs) training 1. Introduction to PLCs 2. Introduction to Schneider PLC logic 3. Troubleshooting PLCs 4. Product select addition to PLC 5. HMI fundamentals Servo motor training 1. Introduction to servos 2. Servo troubleshooting Schneider employees will also use the training facility. With the lab and its miniature robotic palletizing cell, service and maintenance training will occur…

Found in Robotics News & Content, with a score of 2.58

…technology like drones or autonomous automobiles that enhance the delivery of products. Although certain robots are continuously being developed only for the food industry, such as in-store robotics that replenish shelves and robotic dispensers that prepare food, the primary focus for all food and beverage facilities, regardless of the products they distribute, is to automate the storage and retrieval of goods. “Today, the ways in which products are delivered depends on how they will be consumed,” says Cory Hypes, executive vice president of Power Automation Systems. “As consumers continue to desire a more diverse product line, distributors will have to…

Found in Robotics News & Content, with a score of 4.00

…material outside the logistics center, which meant coordinating the delivery of those materials to the logistics center with parts and materials stored on site. Other work areas were also challenged. Receiving, for instance, worked with an out-dated WMS. It wasn’t uncommon to receive new merchandise into the system only to get an order for that same material 10 minutes later because someone in the assembly area was waiting on it. To shore that up, Grob enhanced the standard functionality in SAP’s WMS to support crossdocking, sorting routines for picking orders and the display of pictures of the materials that had…

Found in Robotics News & Content, with a score of 6.14

…a cart in the cart staging area (2) for delivery to one of the assembly lines in the adjacent manufacturing area (3). Similarly, some items may be packaged and staged in the shipping area (4) for delivery to customers in need of spare parts. 2. Pallet-handling AS/RS: Product that is palletized on a Euro pallet receives a license plate bar code label and is delivered to the induction area (6) for the pallet-handling AS/RS (5). The remaining product can be palletized on a Euro pallet that is labeled for induction into the AS/RS (5). 3. Manual reserve storage: Items that…

Found in Robotics News & Content, with a score of 2.53

…the ability to provide plug and play systems and pre-delivery testing of systems prior to installation at the customer’s site all reduces the implementation cost of automation.” “When considering the “total cost of ownership” or the life of the product they’re building and selling manufacturers should also consider that automating their systems domestically may be less expensive than incurring the high costs of poor quality and the rising costs of shipping products to and from off shore facilities,” said Mike Koziel vice president of sales for Eagle Technologies, a Michigan based automation systems provider. “We believe that in the long…

Found in Robotics News & Content, with a score of 4.00

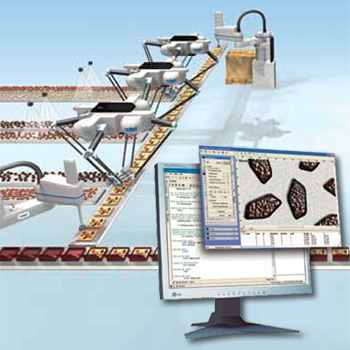

…that each layer represents a different stop on a delivery route or to match store aisles, robotic palletizing systems are flexible, fast and accurate,” says Brian Keiger, general industry sales manager for Grenzebach Corp. “Further, robotic palletizers easily adapt and expand to match changing consumer demands.” Building custom, mixed pallet loads requires a delicate balance between a customer’s depalletizing needs and the stacking force limitations of each case. Previous options include building the load by hand, using a traditional system limited to handling one or two cases at a time, or employing multiple robotic units. Advances in the robotic palletizing…