Editors’ Picks

Found in Robotics News & Content, with a score of 2.90

John Hill knows a thing or two about technology innovation. In a career that spans 50 years, Hill was at the forefront of the development of industrial applications for bar code scanning and radio frequency identification and the first warehouse management software systems. There’s a reason he remembers that the first implementation of bar code scanning outside of point of sale in grocery and retail was in October 1971 at Buick’s Plant 10. “I carried the 50-pound scanner into Buick to give them the demonstration,” Hill recalls. Hill has not rested on his laurels. Still a director at St. Onge,…

Found in Robotics News & Content, with a score of 2.91

You didn’t have to walk far at Modex 2018 to see some type of material handling robot edging by. There were many small, cart-sized autonomous mobile robots (AMR) moving around tugging carts or rolling shelves, collaborative robotic arms that do piece picking, robots with tilt tray sorter attachments or roller conveyor sections on top of them, and bigger robots to move heavy loads. For all the eye-catching arms, grippers, and navigation sensors hanging off these robots, it can be easy to forget how software-driven they are. Robotics vendors may stress features like grippers, or specific material handling tasks their bots…

Found in Robotics News & Content, with a score of 3.66

Justifying the next-gen investment Early materials handling AGVs relied on ground wires, tape, magnets, and reflectors, but today’s robotic lift trucks operate without any added infrastructure and are unrestricted by fixed routes. This offers great strides forward in terms of flexibility, ease of use and productivity. For example, Yale® robotic lift trucks equipped with Driven by Balyo technology build a map of the facility and self-locate in real time, navigating infrastructure free and easily responding to unexpected obstructions. As the competitive landscape continues to intensify, materials handling operations cannot afford an investment that does not pay off, so translating these…

Found in Robotics News & Content, with a score of 6.16

Just one year after its debut, the stationary piece-picking robots from RightHand Robotics (Booth B4087) for warehousing and fulfillment centers continue to evolve to address the individual unit handling needs of e-commerce and omni-channel retailers. “They’re ideal for reliably picking a wide range of variable items at high throughput rates from a tote delivered by an AS/RS or a conveyor,” said Vince Martinellli, head of marketing and products. “To make this happen, we use our RightPick AI—artificial intelligence—software.” The software overcomes the challenge that most robots face: hand-eye coordination. “They have an intelligent gripper, a vision system and software that…

Found in Robotics News & Content, with a score of 7.49

Honeywell Intelligrated announces the launch of TechSight, a real-time augmented reality solution designed to reduce repair time and minimize operational disruption in the event of an unplanned outage. The solution leverages smart glasses and a video conferencing platform to instantly connect on-site technicians with remote Honeywell Intelligrated technical support experts, enabling live service instruction via two-way audio and visual communication. Available to Honeywell Intelligrated Lifecycle Support Services customers, TechSight allows on-site technicians to share their vision, gestures, and voice in real time. Connected, smart glasses enable technicians to receive visual aids like schematics and marked-up images to supplement verbal input,…

Found in Robotics News & Content, with a score of 11.06

Tompkins Robotics (Booth B727), a division of Tompkins International, and RightHand Robotics (Booth B4087), a leader in robotic piece-picking solutions, announced today a collaboration that will combine the world’s first portable, automated sortation system, t-Sort, with RightPick, robotic piece-picking systems, providing unmatched flexibility and throughput for e-commerce and omni-channel fulfillment. “The response from customers visiting our recently re-launched Emerging Technology Center to see these two systems working together has been extremely positive,” said Mike Futch, President of Tompkins Robotics. “Integrating RightHand’s best-in-class piece-picking technology with, Tompkins Robotics t-Sort provides a solution that can flexibly scale from a small operation in…

Found in Robotics News & Content, with a score of 6.87

At a press conference on Tuesday, Universal Logic (Booth C2463) discussed two of its Neocortex G2R (goods-to-robot) cells, which are on display. One of the G2R cells (large) is exhibiting machine trending in manufacturing, while the other G2R cell (medium) is demonstrating the order fulfillment of consumer goods. Each G2R cell will be operating with Universal Logic’s Neocortex 5.0, an AI modular platform software that the company has been developing over the last 10 years. By using sensor data and machine control, the AI software provides the G2R cells real-time reactive control so they can handle upward of 90,000 SKUs—at…

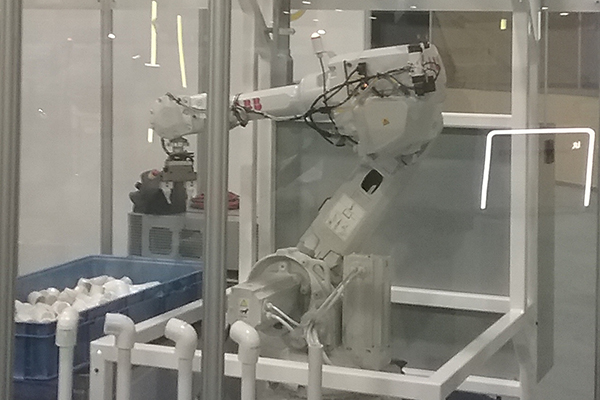

Found in Robotics News & Content, with a score of 10.03

NextShift Robotics (Booth C2363) is unveiling their new robotics system for use in eCommerce warehouses and cellular manufacturing. NextShift Robotics’ unique independent robot/independent worker approach helps e-commerce distribution centers expedite order picking and fulfillment. “NextShift Robotics makes e-commerce fulfillment dramatically more efficient and less costly,” said Mary Ellen Sparrow, co-founder and CEO of NextShift Robotics. “Our robots collaborate with workers, allowing them to pick merchandise quickly and efficiently. Workers stay in their dynamic zones while robots do the rest – loading and unloading heavy order-totes unassisted, and carrying them over long distances. We are able to get very high throughput…

Found in Robotics News & Content, with a score of 5.39

Jim Tompkins, CEO of Tompkins International (Booth B727), said that in spite of his entrepreneurial ventures into distribution and technology businesses, his supply chain consulting, implementation and integration is still going strong—and is busier than ever. “Under Tompkins International, we’ve added three interconnected companies with different purposes,” Tompkins explained. The first, MonarchFx, is an alliance of Tompkins with 3PLs, transportation and technology providers. The group has created a distributed logistics network of fulfillment centers to support retailers and brands shipping direct-to-consumer. “It gives these operations a way to deliver as quickly and as inexpensively as the very large online retailers,”…

Found in Robotics News & Content, with a score of 4.78

“There’s something happening here, What it is ain’t exactly clear”….Stephen Stills A few weeks ago I published Robotics at a tipping point. The piece focused on how 3PLs like DHL, GEODIS and Quiet Logistics are deploying mobile collaborative robots in their e-commerce fulfillment operations. One of the things that struck me is that while the implementations we’re seeing are small, it feels as if the market for mobile collaborative robotics is at a tipping point in materials handling, and it feels as if the adoption rate, poised to become in the next three to five years just another tool in…

Found in Robotics News & Content, with a score of 2.08

To hear John Santagate tell it, in the not-too-distant future we’ll see warehouse dock workers wearing robotic exoskeleton suits and lifting 200-pound boxes in Ironman-esque fashion with no other assistance. With very little exertion, and without the typical ergonomic problems associated with the continuous lifting and moving of heavy items, these futuristic “exosuits” will help ensure higher safety levels—and a speedier process overall—in an area of the warehouse where hefting heavy loads is the norm. This is just one example of how the convergence of humans and robots could play out in the warehouse and distribution center (DC) of the…

Found in Robotics News & Content, with a score of 8.10

Vecna Robotics, a leader in next-generation mobile robotics, and RightHand Robotics, a leader in robotic picking systems, have announced a collaboration to improve the performance of e-commerce order fulfillment. According to a release, the partnership will offer best-in-class solutions to simplify intralogistics and material handling challenges. “We’re excited to have this robust and cost-effective solution become available to all Vecna Robotics and RightHand Robotics customers through this collaboration,” said John Hayes, vice president of sales and marketing at Vecna Robotics. “RightHand has best-in-class piece-picking technology, while Vecna Robotics has best-in-class autonomous mobility,” he added. “Both companies have a shared vision…