Editors’ Picks

Found in Robotics News & Content, with a score of 5.96

…networking and educational opportunities. Source: CAM Mash-Up includes student activities This year's Massachusetts Manufacturing Mash-Up activities included an “on-deck” STEM Challenge. It brought together 300 students from Innovation Pathways, a workforce development program that connects students with career opportunities in high-demand industries. There was also a “speed networking” session for diverse community college students participating in the state’s MassBridge training program. They spoke with company representatives and saw exhibits of additive manufacturing, robotics, and photonics projects that promise to reshape multiple industries, from healthcare and defense to transportation.

Found in Robotics News & Content, with a score of 5.80

…Pathways high schools, community colleges, and universities were also invited to attend. They also participated in a series of STEM (science, technology, engineering, and mathematics) challenges. Massachusetts state Rep Jeff Roy, D-Franklin, and state Sen. Eric Lesser, D-Longmeadow, chairs of the state’s manufacturing caucus, also hosted the state’s annual manufacturing awards ceremony. (See the sidebar to check out the winners.) The local state legislators chose the winners in their respective districts.

Found in Robotics News & Content, with a score of 5.69

…between the different parts of the crop like leaves, stem, and the fruit. Harvest Croo Robotics LLC’s Berry 5 is one the most popular harvesting robots in the market. By using advanced video and image-processing techniques, this robot is capable of safely picking and packing strawberries. The biggest advantage of Berry5 is the speed with which it can complete the task. The Tampa, Fla.-based company's testing has shown that the robot can pluck strawberries from a bush in approximately 8 seconds. Other developers of harvesting robots include Abundant Robotics, Cambridge University, Organifarms, Pickitwise, Tortuga Agricultural Technologies, and Traptic (acquired by…

Found in Robotics News & Content, with a score of 5.35

…methods are generally accepted, and the actions taken to stem the tide are passed down from one staff member to the next. Each temporary shutdown takes an undetermined amount of time, but for our purposes we will estimate 15 minutes each time. That is a downtime cost of $15,000, and if it were to happen once per week, it would be a cost of $780,000/year. It is estimated that robots are deployed for an average of 5 years. Over that 5-year span, the cost of one instance of downtime per week is $3,900,000. Now, to be fair, this number gets…

Found in Robotics News & Content, with a score of 5.07

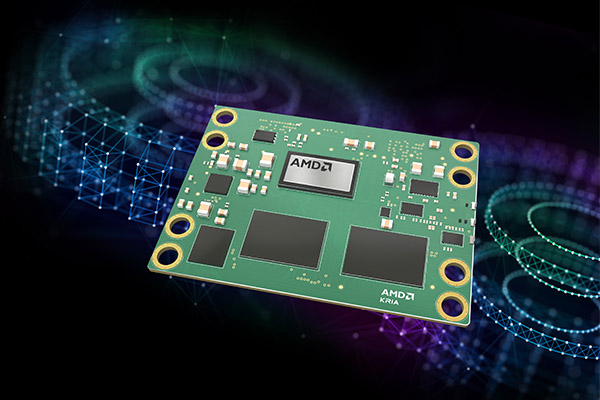

…and build really cool things for both commercial and STEM [science, technology, engineering, and mathematics] educational customers.” AMD said the KD240 supports Matlab Simulink, Ubuntu, and ROS 2. Source: Advanced Micro Devices Scalable SOMs offer accessibility Kria SOMs allow developers to skip the substantial design efforts around the selected silicon device and instead focus on providing differentiated, value-added features, said AMD. Connector compatibility enables easy migration between the K24 and K26 SOM without changing boards, said AMD. This allows system architects to balance power, performance, size, and cost for energy-efficient systems, it said. “The K24 complements the K26,” said Khona.…

Found in Robotics News & Content, with a score of 4.58

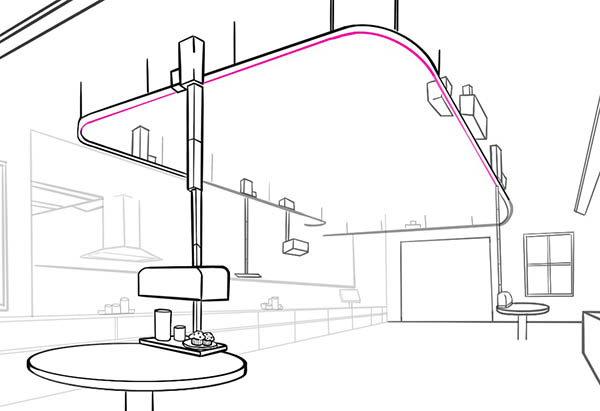

…midsize food-service businesses? Al-Beik: Across the board, the challenges stem from logistics highly dependent on human labor. Even at capacity, the output is limited — human workers can't compete with 80 digital orders coming through in a single hour. As a result, customers have less of a burden when making an order, but they take it on when they wait to pick up their orders. Today, with the labor shortage alone, the logistics are overwhelmed, and the customer experience inevitably plummets. Therefore, the biggest challenge is upgrading logistics to support a much more streamlined input and output retail system while…

Found in Robotics News & Content, with a score of 3.97

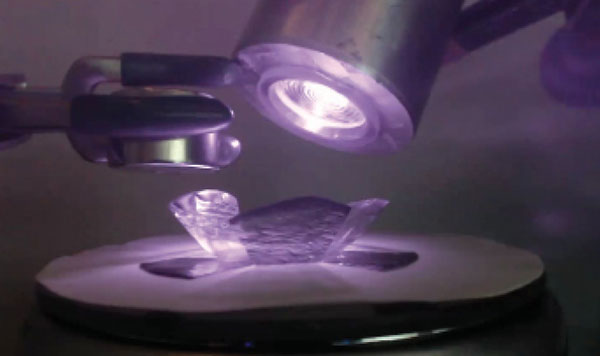

…One of the biggest obstacles currently encountered by engineers stems from the fact that the material science supporting soft robotics is still in the early stages of its development. As a result, a number of sticking points continue to hinder soft robotics evolution. For example, the current collection of materials used by soft robot developers offers only limited functionality. Although elastomers and fluids have proven to be a good match for the mechanical properties of biological materials, they typically do not have adequate electrical, thermal or electromagnetic properties to replace the functions of motors and electronics. This shortcoming, however, has…

Found in Robotics News & Content, with a score of 3.81

…efficiency: analog processing. The catalyst for these development efforts stems from the fact that the leading processor contenders—namely GPUs, FPGAs and ASICs—require a digital data format. The catch here is that sensor output naturally comes in analog form. This means that digital systems require data to go through an analog-to-digital conversion process, which can increase the system’s latency, power consumption and cost. To address this problem—and to facilitate inclusion of AI in smart sensors—companies like Syntiant and AIStorm have chosen to provide analog data chips. In general, analog processors solve problems by representing variables and constants with voltage. The systems…

Found in Robotics News & Content, with a score of 3.72

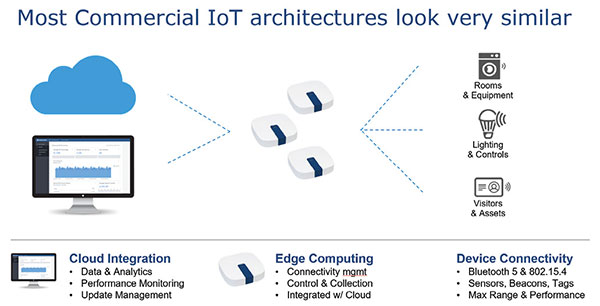

…with a number of connectivity challenges. These challenges often stem from features of the operating environment. For example, in smart buildings, connected retail and smart warehouses, designers must deal with the presence of walls, floors, inventory and human occupants, which can degrade wireless signal propagation. Other challenges arise as a result of harsh radio frequency (RF) environments in which the commercial IoT system must compete with extraneous RF signals and noise over a broad frequency range. This heightens the importance of RF coexistence. Consideration of these connectivity challenges and many other issues should begin early in the development process, especially…

Found in Robotics News & Content, with a score of 2.97

…typical sources of customer value delivered by a warehouse stem from transaction-linked capabilities that enable successful deliveries and returns, such as ease, flexibility, velocity, visibility and reliability. Customer value can also be derived from product-linked features such as availability, personalization and quality. Needless to say, each business is unique and requires a clear definition of customer value that is specific to their product offerings, selling models, customer segments, markets and channels. Figure 4 illustrates the typical levers that a warehouse operation can pull to create customer value. These customer values should drive the definition of use cases and expected outcomes…