Editors’ Picks

Found in Robotics News & Content, with a score of 7.43

…— 100 times faster than human efforts and other inventory-collection technologies. In addition, the system can serve as a digital replica of a physical warehouse to benefit not only management, but also performance optimization, said the company. It said its software can simulate, optimize, and forecast future scenarios, freeing warehouse personnel to engage in more complex tasks. Dexory looks to DB Schenker for global growth “The potential and evident success of Dexory’s technology within the global logistics landscape in a short space of time is impressive,” said Paulina Banszerus, head of venture capital at Schenker Ventures. “Dexory has engineered a…

Found in Robotics News & Content, with a score of 9.28

…are needed, without the cost or hassle of physical inventory management. “Digital Source unlocks a new way of managing supply chains,” said Shai Terem, CEO of Markforged, in a release. “Every day a manufacturing line is down due to broken or worn parts can cost millions of dollars in lost productivity.” “Availability of spare parts is critical to manufacturers’ success — but keeping an extensive physical inventory ties up capital in parts that may go untouched for years,” he noted. “Digital Source not only can simplify logistics, but [it] can also build resiliency into the supply chain and increase profitability…

Found in Robotics White Papers & Archives, with a score of 9.13

…higher speed and accuracy. The gains are also prominent in improving efficiency in overall warehouse operations, including order fulfillment, inventory management, and many administrative tasks. Download this doc to learn more.

Found in Robotics News & Content, with a score of 3.62

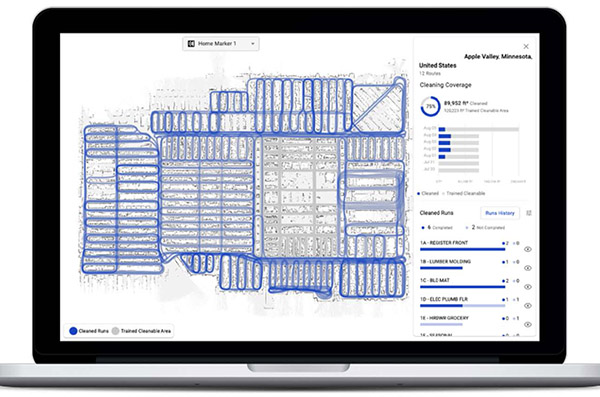

…world. Brain Corp said OEM partners use its cloud-connected platform to build scalable, self-driving robots to clean floors, move inventory, and sense environmental data, automating workflows for end customers. Want to learn more about fleet management? This article was featured in the June 2024 Robotics 24/7 Special Focus Issue titled “Orchestrating mobile robot fleets for success.”

Found in Robotics News & Content, with a score of 4.80

…human errors, the company explained. YOLO to help with inventory management ResGreen last week also announced its “You Only Look Once” or YOLO algorithm for identifying low-stock or vacant storage areas. “YOLO’s renowned real-time, single-pass, object-recognition framework lays the foundation for predictive analytics, dynamic resource allocation, and continuous operational improvement – putting us at the forefront of intelligent manufacturing and warehouse management,” said Patel. The system offers sub-milisecond detection, shares data for inventory oversight, and can track the stocking of multiple objects concurrently, said the company. Users can also configure its sensitivity or granularity level and get predictive models for…

Found in Robotics News & Content, with a score of 8.90

…automated piece-picking systems to address challenges including high SKU inventories, complex packaging, and fragile items. The company said its systems support goods-to-robot (G2R) use cases. It claimed that its Hypercare support covers everything from concept exploration to onsite installation. “Our AI-driven SightWorks vision software and associated technologies provide the foundation for all of our warehouse solutions,” said Derik Pridmore, CEO of OSARO. “[They are] available to strategic partners, including FANUC’s ASI network of robot integrators, to build the custom applications and control technologies required to identify, pick, and place any object.” “By collaborating on engineering and business development, FANUC and…

Found in Robotics News & Content, with a score of 4.64

…control software to help companies respond to high SKU inventories, complex packaging, and fragile items. The San Francisco-based company offers Hypercare support, from concept exploration to installation on site. It added that its systems support goods-to-robot (G2R) use cases on the warehouse floor. Cognex solves reading challenges Founded in 1981, Cognex claimed that it is a leading global provider of machine vision hardware and software to manufacturers and distributors. The Natick, Mass.-based company said its products can automate the location, identification, inspection, and measurement of discrete items such as mobile phones, electric vehicle batteries, and e-commerce packages. Cognex said it…

Found in Robotics News & Content, with a score of 3.75

…has to replenish more than 100 stores and an inventory of more than 500 SKUs to manage. ForwardX said its vision-based AMRs can handle payloads ranging from 661 to 1,336 lb. (299.8 to 605.9 kg), automating both each and case picking in one warehouse. The Beijing-based company added that it provides tailored retail systems combining RFID scanners, scales, and other accessories to meet a variety of business demands. POLA ORBIS achieves results with automation In response to POLA ORBIS's need to modernize its picking process, ForwardX Robotics customized its mobile robots by adding precision scales for weighing items. The AMRs…

Found in Robotics News & Content, with a score of 2.29

…per day.” This year, Locus is building up its inventory to ship thousands of robots to help clients in North America and Europe handle the peak holiday shopping season, he said. “We designed our solution from the beginning to be scalable,” said Faulk. “Existing users can uncrate a robot, power it up, and begin using it in five minutes. When they're done with the robot, they can put it back into the carton and ship it back.” Customers grow AMR fleets Of its AMR-assisted picks, about 80% come from existing Locus Robotics customers, and 20% from new ones added over…

Found in Robotics News & Content, with a score of 2.96

…service, quality, and quick turnaround as they manage the inventory, distribution, and transportation of medical supplies.” BayCare said its unified distribution model has enabled it to maximize purchasing efficiencies and manage supply pipelines, including during the COVID-19 pandemic. Before the adoption of robotics at the distribution center, the order-picking process involved team members pushing carts weighing nearly 300 lb. up and down each aisle, guided by voice technology through headsets. While software already helped make picking routes efficient, the heavy carts limited speed and made the picking process physically taxing for team members, explained Celiberti. BISC benefits from collaborative mobile…

Found in Robotics News & Content, with a score of 1.96

…Inc.’s retail supply chain. The first part was about inventory productivity. In this one, we look at how the New York-based retailer is incorporating sustainability into its practices and goals. Back in May, I sat in on a roundtable discussion on sustainability at the American Supply Chain Summit. Keelin Evans, Macy’s vice president of sustainability, led a lively conversation among the executives. The speakers made it clear that workforce and environmental sustainability has become integral to supply chain management. For her part, Evans’ message was that sustainability is one of the pillars of Macy’s supply chain modernization, as the department…

Found in Robotics News & Content, with a score of 8.81

…we look at the department store leader’s focus on inventory productivity. Can a 165-year-old department store chain evolve to meet today’s retail shopper and compete with fast fashion, off-price, and pure e-tailers? And, if so, what is the role of supply chain in that transformation? Those are questions that Macy’s Inc., which had annual net sales of more than $24 billion in fiscal year 2022, began to answer before COVID-19. That’s when it launched the reinvention of the supply chain that largely supports the Macy’s brands. One metric for the company is the “inventory productivity,” according to Dennis Mullahy, chief…