Editors’ Picks

Found in Robotics News & Content, with a score of 7.00

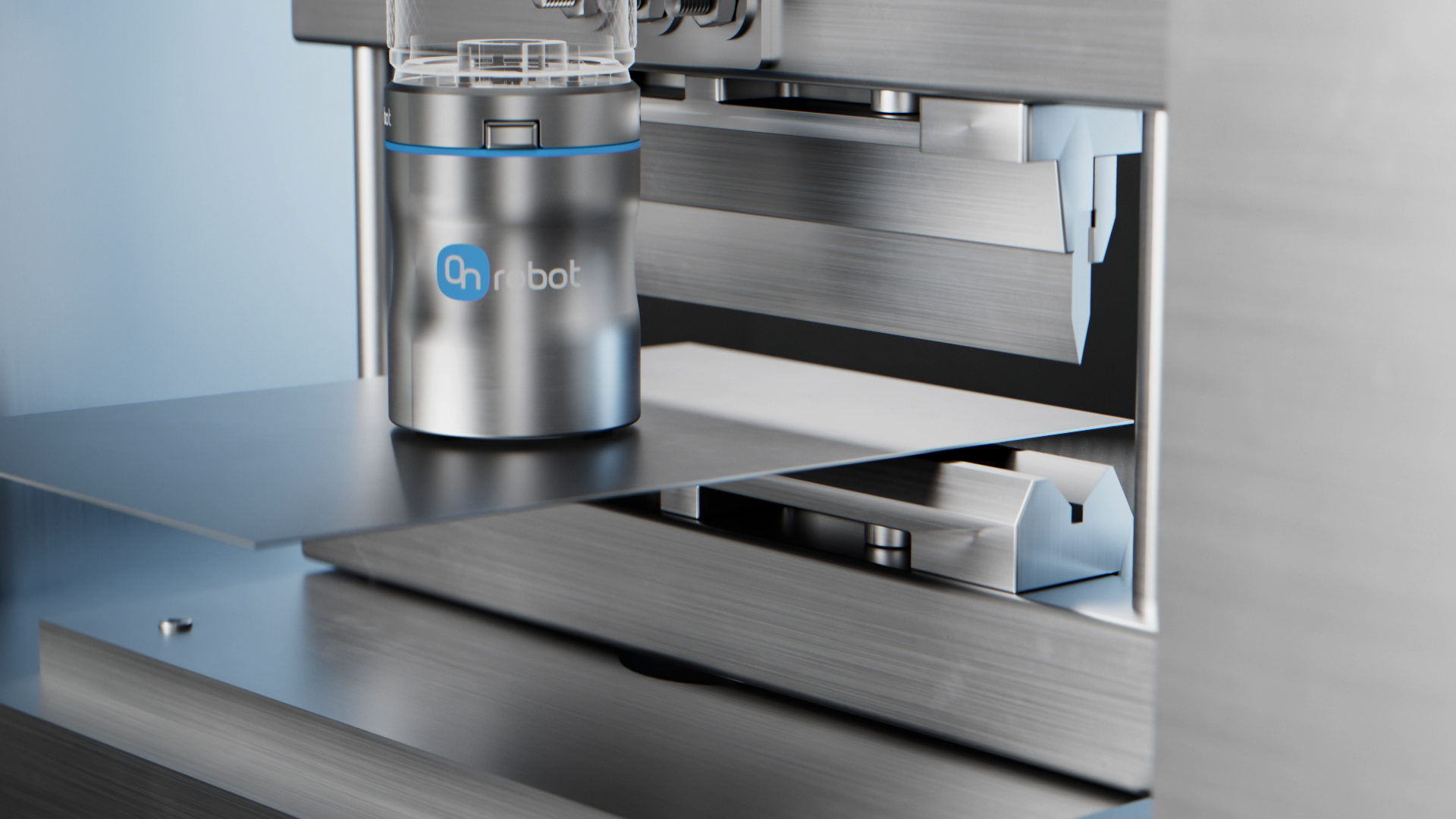

…same year. In 2019, the company acquired Blue Workforce's technology for its RAGNAR delta robot. OnRobot now has offices in 10 countries. Last year, the company launched a three-finger electrical gripper, the OnRobot Eyes vision system, and screwdriver and sanding tools. It also launched the 2FG7 cleanroom-ready parallel gripper. OnRobot builds MG10 magnetic gripper for smoother handling Today, OnRobot announced the MG10, a new electric magnetic gripper with programmable force features and built-in grip and part-detection features. The company said the MG10 is designed for materials handling, assembly, and machine-tending applications in manufacturing, automotive, and aerospace applications. “Standard magnetic grippers…

Found in Robotics News & Content, with a score of 8.88

…components grabbed the spotlight in the media, revealing the technology’s potential to swiftly respond to unforeseen disasters. But this isn’t necessarily a new use case of additive manufacturing (AM). Over the course of the technology’s adoption, 3D printing hardware and materials have gained traction in regions of earthquakes, conflict and a variety of natural disasters. A carry-on printer Eric James, executive director of Field Ready, occasionally flew with a 3D printer as part of his allowable carry-on luggage. Over the years, he had to figure out how to fit a 3D printer into a commercial jet’s overhead bin and how…

Found in Robotics News & Content, with a score of 21.06

3D Systems has been selected by Raytheon Technologies and the Combat Capabilities Development Command (DEVCOM) Army Research Laboratory (ARL) as part of a research project titled “Research for Virtual Design and Qualification Process for Additively Manufactured Parts Optimized for Multi-Laser Machines” awarded through the National Center for Manufacturing Sciences’ (NCMS) Advanced Manufacturing, Materials, and Processes (AMMP) program. Working in conjunction with Raytheon Technologies, the Penn State Applied Research Lab, Johns Hopkins University and Identify3D, the goal is to optimize a component relative to an Army modernization product to maximize cooling and improve overall system performance. Using additive manufacturing (AM) to…

Found in Robotics News & Content, with a score of 8.53

…consumer packaged goods (CPG), food & beverage, retail and manufacturing, with a focus on how shippers in various sectors and approach specific pain points, among other topics. The report observed that 92% of its respondents maintain that a yard management system (YMS) is something that can add value but only 25% are actually using a YMS. And the report explained that this gap in perceived value and real-world adoption of YMS is related to a few different factors, such as organizations prioritizing investments in transportation management systems (TMS) and warehouse management systems (WMS), as well as deficiencies in legacy YMS…

Found in Robotics News & Content, with a score of 17.69

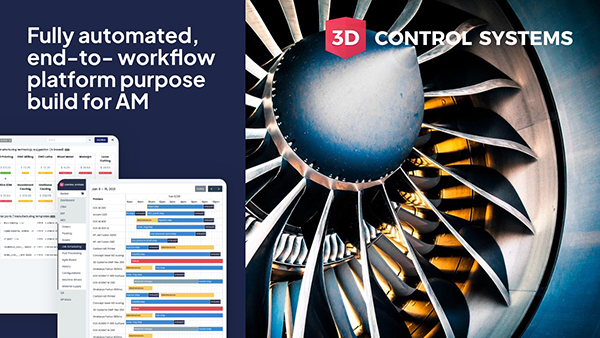

…Control Systems has just launched a new AM (additive manufacturing) workflow management software, dubbed ZAP, powered by AI and ML (machine learning). “The automated workflow platform integrates disparate 3D printer systems, frees users of risk for future technology integrations, and eliminates costs for system migration, deployment, and upgrades. This makes the new ZAP platform the ideal solution for advanced manufacturing factories that are looking to address requests that range from automating internal 3D printers to managing external production more efficiently,” according to the company's announcement. 3D Control Systems launches ZAP, an AI-powered 3D printing workflow manager. Image courtesy of 3D…

Found in Robotics News & Content, with a score of 14.36

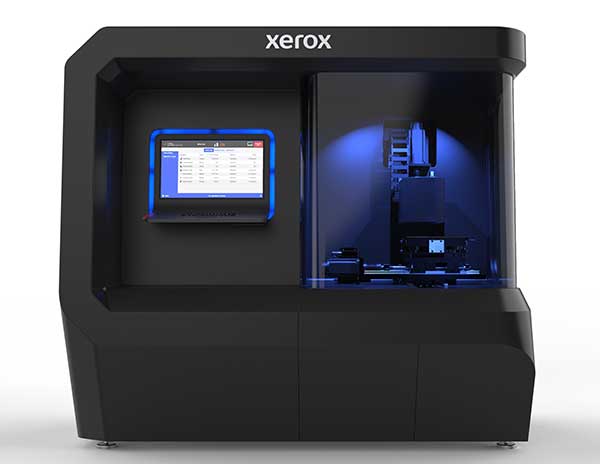

…(NPS) announces a strategic collaboration focused on advancing additive manufacturing research, specifically 3D printing, which has the potential to transform the way the military supplies its forward-deployed forces, organizations note. As part of a Collaborative Research and Development Agreement (CRADA), NPS was the first to receive an installation of the Xerox ElemX Liquid Metal Printer on the university campus in December. The Xerox solution will provide NPS faculty and students with hands-on exploration of new ways the technology can deliver on-demand 3D printing of metal parts and equipment. “The military supply chain is among the most complex in the world,…

Found in Robotics News & Content, with a score of 14.67

…industries accessible to thousands of unemployed workers and aspiring manufacturing professionals across the state, organizations report. “This is an application of VR technology that extends well beyond what many of us are familiar with from gaming or consumer apps. It's about harnessing the potential of immersive learning to train and certify employees on critical, in-demand skills at unprecedented scale,” says Tony Wojciechowski, chief human resource officer at HPT. “It's providing employers like us with a powerful new tool to train, recruit, and hire talent right here in Alabama.” The latest collaboration between AIDT and HPT, a partnership that dates back…

Found in Robotics News & Content, with a score of 16.41

…solutions to address social distancing in warehouses – including technology that traces each employee’s move – robotic systems are easier to implement and less invasive. “Keeping people in place and using a virus-resistant robot to move goods around respects people’s privacy and keeps them safe at the same time,” Mr. Klappich added. In addition to this short-term value, G2P systems also drive broader long-term improvements in efficiency and productivity. Advanced systems also offer additional benefits such as improved storage density. Gartner also predicts that through 2024, 50% of supply chain organizations will invest in applications that support artificial intelligence and…

Found in Robotics News & Content, with a score of 9.99

…to execute the packing process. Labels are printed and applied to the cartons, which are then pushed onto the takeaway conveyor (9). The cartons pass through a scan and weigh station. Cartons that are out of tolerance are diverted to an inspection station and then to an automatic print-and-apply station. Cartons that pass the weight and scan audit are conveyed to shipping and diverted to the right dock door based on the parcel carrier. System suppliers System design & integration, voice recognition, warehouse control system, and print & apply: The Numina Group Robotics: Waypoint Robotics Motor driven roller conveyor: TGW…

Found in Robotics News & Content, with a score of 18.61

…of the accelerated geometry kernel used to build additive manufacturing (AM) hardware and software solutions, announce a long-term licensing agreement with HP to help power their next-generation cloud and edge-based digital manufacturing solutions, the companies report. The collaboration is designed to bring performance, efficiency, automation, and extensibility to the company's growing portfolio of digital manufacturing products, the companies add. This agreement demonstrates HP's commitment to industry innovation in three key areas; quality, performance and automation. “From the very beginning, HP recognized the potential of Dyndrite's kernel technology. As the first member of the Dyndrite Development Council, we quickly identified areas…

Found in Robotics News & Content, with a score of 11.10

…printing gains increasing support a feasible alternative to traditional manufacturing, it also creates opportunity for a wave of new cybersecurity risks, from theft of design intellectual property (IP) to malicious destruction of parts and planned system failures. 3D printing has been in the spotlight as the market incorporates new and more sophisticated offerings sporting novel printing technologies and advanced materials choices. At the same time, this next-generation of high-powered printers has been retooled to fit the needs of mainstream design and manufacturing engineers, from a cost and accessibility standpoint. The result has been increased adoption of 3D printing for industrial-grade…

Found in Robotics News & Content, with a score of 5.82

Metal additive manufacturing (AM) stands poised to expand its footprint in the manufacturing sector, transitioning from a proven prototyping tool and small-lot fabrication process to mainstream part production. But there’s a catch. Today’s AM technology isn’t predictable and repeatable enough to be cost-effective for companies that want to use AM to mass-produce parts. Currently, engineers must go through an iterative process of trying different printing parameters before they can identify the combination that will enable them to build parts that meet the necessary quality standards. AM Process Simulation Software Buyer’s Checklist When choosing additive manufacturing (AM) process simulation software, cost…