Editors’ Picks

Found in Robotics News & Content, with a score of 26.81

…plans to use the funding to launch the M1 additive manufacturing system, which includes a welding robot, software, and control systems to 3D-print metal parts. MX3D also said it will accelerate development of the MetalXL software and control system to turn existing welding robots into industrial-grade 3D metal printers. Since 2015, MX3D has been developing robotic 3D metal-printing technology. It claimed that its technology allows for more flexibility and optimization in design and can save on materials, lead time, and costs across industries including maritime, oil and gas, and construction. The company added that it was a pioneer in robotic…

Found in Robotics News & Content, with a score of 13.77

…acquisition companies (SPACs), a recent trand in venture capital. Additive manufacturing contributed to this total. After that was supply chain and logistics, with more than $1.7 billion in reported transactions. This is not surprising, given the surge in e-commerce during the pandemic and ongoing interest in robots for materials handling and delivery. Healthcare companies, mostly providers of surgical robotics, were involved in more than $250 million worth of deals, followed by agricultural robots, with more than $130 million in total transactions. Note that this slideshow of the top 10 robotics transactions is not a comprehensive listing of the dozens of…

Found in Robotics News & Content, with a score of 28.43

…network with the purchase of a Ti6Al4V Sapphire metal additive manufacturing system. Primus Aerospace is a a leading contract manufacturing partner to aerospace and defense OEMs and Tier 1 suppliers worldwide. Established in 1989, the Lakewood, Colo.-based company has grown into a vertically-integrated manufacturing operation. It also operates a sales and engineering office in Arizona and a distribution warehouse in the Netherlands. Primus' customers include Lockheed, Boeing, Northrop Grumman, General Dynamics, and Raytheon. VELO3D said its integrated, full stack offering of software, hardware, and process-control innovation allows engineers to accelerate product innovation, be more responsive to market needs, and reduce…

Found in Robotics News & Content, with a score of 25.59

…it is merging with JAWS Spitfire Acquisition Corp. The additive manufacturing company said it expects to be listed on the New York Stock Exchange under the ticker symbol “VLD” once the transaction is completed, which is expected to happen in the second half of 2021. Campbell, Calif.-based VELO3D said its proprietary technology for 3D printing of metals integrates software, hardware, and process-control innovations. Manufacturers can use VELO3D's Flow print-preparation software, Sapphire laser powder-bed additive manufacturing (AM) system, and Assure quality-assurance software to reduce costs, improve quality control in serial production, and be more responsive to market needs, claimed the company.…

Found in Robotics News & Content, with a score of 23.55

…recently selected its VELO3D Sapphire system. Chromalloy will use additive manufacturing for maintenance, repair, and operations (MRO) projects in the aviation and energy markets. Palm Beach Gardens, Fla.-based Chromalloy develops systems to reduce operating expenses and extend the life of gas turbine engines. The company, a subsidiary of Sequa Corp., is authorized by the U.S. Federal Aviation Administration, the European Union Aviation Safety Agency, and other national aviation authorities. It is also qualified under ISO (International Organization for Standardization) and National Aerospace and Defense Contractors Accreditation Program. Chromalloy to use AM to extend engine life Industries are increasingly adopting additive…

Found in Robotics News & Content, with a score of 24.10

…wield advanced technologies like generative design (GD) software and additive manufacturing (AM) to deliver TIGER (Transforming Intelligent Ground Excursion Robot), a concept vehicle announced earlier this month. As a follow-on to Elevate, its first UMV concept with moveable legs, the TIGER X-1 concept vehicle is based on a modular platform architecture that includes a sophisticated leg and wheel locomotion system, 360-degree directional controls, and a range of sensors for remote observation. The UMV can transform from four-wheel drive to four-leg walking and operate without a crew to perform different missions such as delivery in urban settings, transport of critical supplies…

Found in Robotics News & Content, with a score of 18.53

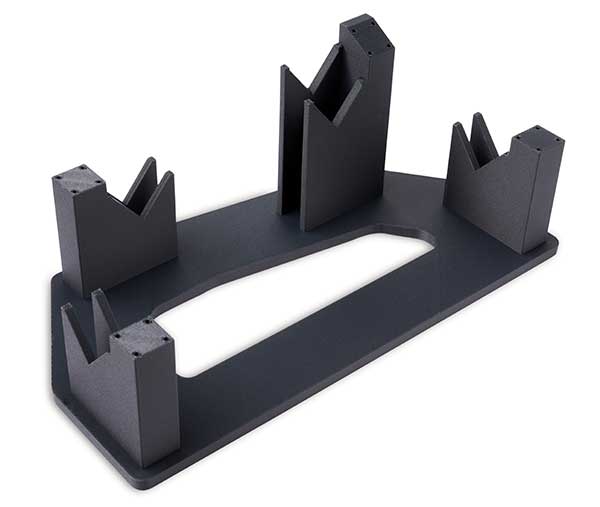

…makes carbon fiber more accessible to the engineering and manufacturing community with high-performance F170, F270 and F370 3D printers. The material properties of FDM ABS-CF10, featuring 10% chopped carbon fiber, an alternative to metal parts. The material is said to be stronger and stiffer than standard ABS, without the weight of metal, and can be printed with accuracy, Stratasys notes. QSR Support water-soluble material enables ability to 3D print intricate and complex parts without manual support removal. Stratasys’ internal analysis suggests the additive manufacturing market for polymer jigs and fixtures is expected to grow at a 14.2% annual rate between…

Found in Robotics News & Content, with a score of 9.53

…But this isn’t necessarily a new use case of additive manufacturing (AM). Over the course of the technology’s adoption, 3D printing hardware and materials have gained traction in regions of earthquakes, conflict and a variety of natural disasters. A carry-on printer Eric James, executive director of Field Ready, occasionally flew with a 3D printer as part of his allowable carry-on luggage. Over the years, he had to figure out how to fit a 3D printer into a commercial jet’s overhead bin and how to operate it in war-torn, disaster-hit regions where electricity and high-speed internet connection are not always guaranteed.…

Found in Robotics News & Content, with a score of 20.19

…for Multi-Laser Machines” awarded through the National Center for Manufacturing Sciences’ (NCMS) Advanced Manufacturing, Materials, and Processes (AMMP) program. Working in conjunction with Raytheon Technologies, the Penn State Applied Research Lab, Johns Hopkins University and Identify3D, the goal is to optimize a component relative to an Army modernization product to maximize cooling and improve overall system performance. Using additive manufacturing (AM) to address this need is a novel approach to the project that covers the entire part lifecycle including determining performance requirements, topologically optimizing the design, manufacturing the part with attention to process monitoring for quality control, component performance validation,…

Found in Robotics News & Content, with a score of 22.73

…from the Air Force Research Laboratory (AFRL), Materials and Manufacturing Directorate, Manufacturing and Industrial Base Technology Division, to advance qualification and certification of additive manufacturing materials, processes, and products throughout the supply chain. RIC Timeline and Details Launch: February 9, 2021 Eligibility: All participants (lead and subproposers) must be America Makes members. Informational Webinar: February 15, 2021 at 2 p.m. EST. Registration is required. Submission Deadline: Monday, March 1, 2021 before 5 p.m. EST Anticipated Award(s) Announcement: March 15, 2021 One award per topic is anticipated: Topic 1 $50K, Topic 2 $75K, and Topic 3 $60K “We have been encouraging…

Found in Robotics News & Content, with a score of 17.26

3D Control Systems has just launched a new AM (additive manufacturing) workflow management software, dubbed ZAP, powered by AI and ML (machine learning). “The automated workflow platform integrates disparate 3D printer systems, frees users of risk for future technology integrations, and eliminates costs for system migration, deployment, and upgrades. This makes the new ZAP platform the ideal solution for advanced manufacturing factories that are looking to address requests that range from automating internal 3D printers to managing external production more efficiently,” according to the company's announcement. 3D Control Systems launches ZAP, an AI-powered 3D printing workflow manager. Image courtesy of…

Found in Robotics News & Content, with a score of 25.58

Fathom Manufacturing announces the acquisition of Summit Tooling and Summit Plastics, a precision tooling and injection molding services provider specializing in small-to-medium prototype injection molds for the domestic market. This acquisition will expand Fathom's domestic injection molding capabilities, companies report. “Summit's focus on customers during the design, prototyping and low-volume production stages of a product's life cycle perfectly aligns with Fathom's unique customer value proposition. We're excited to work with the Summit team to explore opportunities to even better serve its customers through Fathom's comprehensive digital manufacturing platform while also providing Fathom's existing customer base with expanded domestic quick-turn precision…