Editors’ Picks

Found in Robotics News & Content, with a score of 3.89

…following considerations for mobile robots: The role of open-source software in developing and using mobile robots How to improve ease of use for workers on the factory or warehouse floor The types of data that managers need for efficiency and throughput The need to coordinate processes, robots, and people Robotics as a service (RaaS) and mobile robot fleets The need for interoperability among systems from multiple vendors and current standards efforts Listen in today!

Found in Robotics News & Content, with a score of 0.62

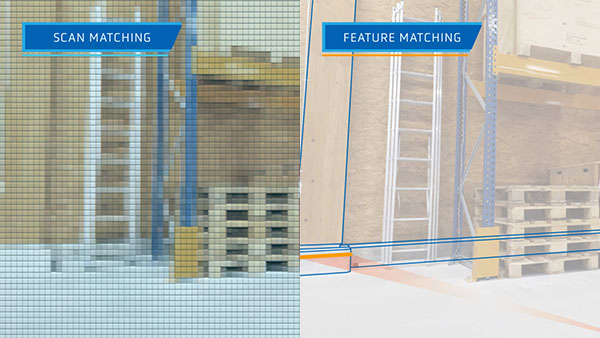

…interact with them. Which natural navigation technology should you choose? Each business has its own unique challenges. But for ease of use, accuracy and the robustness in operation, we believe ANT® navigation is the clear choice for any vehicle type. Related Resource Comparing Autonomous Navigation Technologies If you are looking to develop a new automated guided vehicle or mobile robot (or even upgrade an existing model), choosing the right autonomous navigation technology will be key to its success. Watch our recent webinar to take a deeper dive into more navigation technologies (including line following and tag following) View Now.

Found in Robotics News & Content, with a score of 1.37

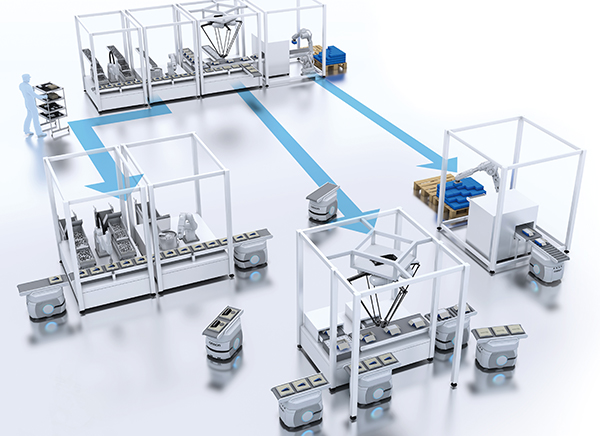

Next week at the MODEX 2022 supply chain trade show, Universal Robots ApS will have several live demonstrations highlighting how its customers are using its collaborative robots. Odense, Denmark-based Universal Robots (UR) is the market leader in the cobot space, with a 44% to 47% market share. Cobots go to work depalletizing At Universal Robots' booth B2805, visitors will learn how automation company Mujin is using Universal Robots' UR10e for mixed case depalletizing. “Collaborative robots have completely changed the way industry utilizes robotics,” says Josh Cloer, director of sales at Mujin. “UR brings flexibility, ease-of-use and ready-to-deploy tools making it…

Found in Robotics White Papers & Archives, with a score of 6.17

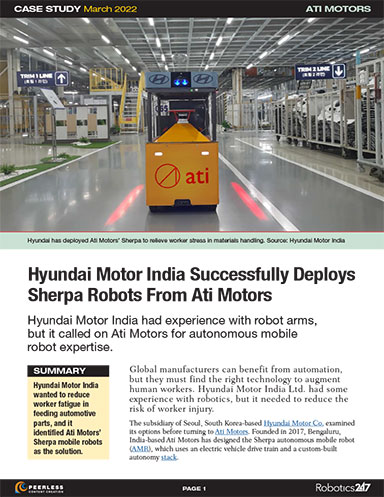

…number of options before choosing Ati Motors. Ati Motors' Sherpa autonomous mobile robots (AMRs) stood out because of their ease of use and the Bengaluru, India-based company's strong customer support through a robotics-as-a-service (RaaS) model. The AMRs have an electric drive train and a custom-built autonomy stack. Unlike automated guided vehicles (AGVs), Ati said its AMRs require less infrastructure and allow for more sophisticated fleet management. Not only did Hyundai Motor India's deployment of its first Sherpas reduce dependence on manual operations, but it also led the company to consider adding more robots for different manufacturing processes. Learn more in…

Found in Robotics News & Content, with a score of 1.91

…platform for its expansion. The company said Smart+ offers great remote/offsite access features such as versatile mission planning, point-and-click ease of use, elevator integration, immersive observability, vision AI, backend connectivity tools, and more. It said it has partnered with Singapore Technologies, ROS Industrial, Mobile Industrial Robots, Singapore Land Authority, Infinium Robotics, among others. Incorporated in 1992, Patec Group supplies the automotive and aerospace industries. It is headquartered in Singapore and employs more than 10,000 people. The company has two research centers, five production sites, and six service centers around the world.

Found in Robotics News & Content, with a score of 1.84

…added that it has designed the cobot's interface for ease of use, and its plug-and-play concept makes it accessible to SMEs. The robot is suitable for industrial applications including assembly, quality assurance, palletizing, and pick-and-place tasks, said Kassow. Its seventh axis, or “wrist joint,” and safety-compliant design allow for human-robot collaboration, the company said. Users can move the relatively lightweight KR1018 to perform tasks in different areas of a facility. The seventh axis gives the KR1018 a small footprint of 160 x 160 mm (6.2 x 6.2 in.), maneuverability, and an increased range of motion, said the company. It can…

Found in Robotics News & Content, with a score of 1.35

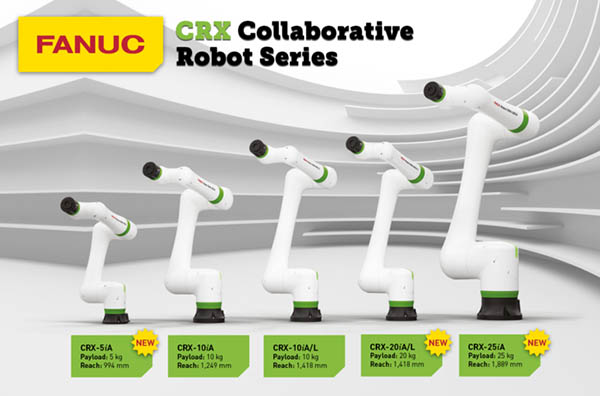

…Argentina, Brazil, Canada, and Mexico. CRX cobots designed for ease of use FANUC claimed that its collaborative robots are safe, easy to use, reliable, and suitable for a wide range of applications, including inspection, machine loading and unloading, packing, palletizing, vision-guided pick and place, sanding, and welding. The CRX robots can detect external forces in the workspace, stopping safely when making contact with a person or object. This technology allows the cobots to work safely alongside people without the need for expensive guarding. FANUC said its new CRX-5iA, CRX-20iA/L and CRX-25iA collaborative robots can handle payloads of 5, 20, and…

Found in Robotics News & Content, with a score of 0.56

…are constantly innovating to improve their robots’ performance and ease of use, allowing more robots to move efficiently and safely through complex traffic situations. Five rapidly changing technologies are worth watching as they drive advancements and deployments of AMRs. 1. AI goes beyond the buzz to make AMRs smarter, safer “Artificial intelligence” remains a confusing buzzword, inconsistently defined across industries and applications. But for AMRs, the technology means smarter robots that can teach themselves how to perform tasks that were previously difficult or impossible without expensive and time-intensive coding. AI requires a significant amount of computational power, which is becoming…

Found in Robotics News & Content, with a score of 0.82

…abstraction using AI and machine learning. There is also a push by many robotics and software vendors to improve ease of use. With this bottleneck removed, more companies are adopting robots for flexible manufacturing. Nobody wants technology for its own sake, but the latest generation of industrial, collaborative, and mobile robots offers greater efficiency, productivity, and access to a wider client base, as well as continued competitiveness. About the author Bryan Christiansen is the founder and CEO of Limble CMMS. Limble provides computerized maintenance management system (CMMS) software intended to help manufacturing managers organize, automate, and streamline their maintenance operations.

Found in Robotics News & Content, with a score of 1.61

…one. Quality: Raymond said its Automatic WMS can eliminate human error for faster, more accurate, and streamlined order processing. Ease of use: Advanced controls provide precise positioning and load-handling functions, along with dynamic hoist braking, to help minimize brake wear and increase operator confidence. Operator comfort: With top- and bottom-mounted guide rails, full-height mast, and an ergonomically designed compartment, the Transtacker offers stability for operator comfort and productivity. The company said that it and its entire network of more than 100 authorized Solutions and Support Centers throughout North America will sell, support, and service the new Automated TRT vehicles.

Found in Robotics News & Content, with a score of 1.01

…potential in a wide array of industrial settings. The ease of use and the fast learning cycle make it one of the most scalable platforms in the industry.” Tallinn, Estonia-based Metaplanet said it invests in early-stage companies working on potentially disruptive technologies. It added that it helps startups with knowledge and network across sectors. Munich, Germany-based Vsquared Ventures said it backs companies with the potential to become global leaders in future markets created by technological breakthroughs. Its portfolio includes companies such as Isar Aerospace, IQM Quantum Computing, Morpheus Space, and Zama.ai. Ahren Innovation Capital said it invests in startups at…

Found in Robotics News & Content, with a score of 0.62

…in tasks that call for less lift capacity.” Such limitations are valid concerns, but cobots still offer value and ease of use. “It’s important to note that the challenges involved in deploying cobots are orders of magnitude smaller than the challenges involved with traditional industrial automation,” said Campbell.