Editors’ Picks

Found in Robotics News & Content, with a score of 6.75

…with indoor forming and now agricultural robotics.” While autonomous tractors are already being deployed around the world, different crops require smaller robots, she explained. “If you look at the $45 billion specialty crops market, the cost of production is 3x that of row crops,” said Reddy. “The way farms are designed is completely different than for grains harvested with combines.” “The other piece we saw in agricultural technology was a crowded space around fruit like apples and strawberries, but table grapes are a $1 billion industry in California, which has 99% of the U.S. market,” she noted. “We have a…

Found in Robotics News & Content, with a score of 6.68

…a log, moving dirt, or pulling something with a tractor.” How much customization is necessary? “It will vary by customer platform and needs,” replied Gordon. “The vehicle and the task will drive how many sensors they need and where they're placed. It's a collaboration between the Summit Core software, Behaviors for driving vehicles, and Services to integrate and manage autonomy.” “Sensor fusion is important, and navigation and waypoint actions are within Summit Core,” said Andrew Lycas, principal roboticist at Stratom. “We want to understand the vehicle state and objects in varied environments. It's then up to the users to determine…

Found in Robotics News & Content, with a score of 6.65

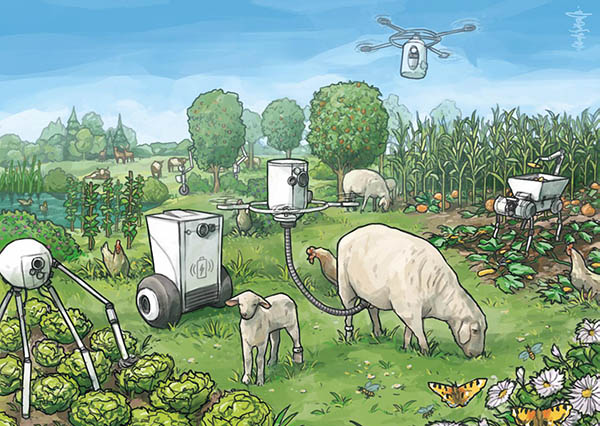

…crops. The other is a dystopia in which large, tractor-like robots subdue the landscape through heavy machinery and artificial chemicals. Daum described the utopian scenario as a mosaic of rich, green fields, streams, and wild flora and fauna, where fleets of small agricultural robots fueled by sustainable energy flit around the fields, their whirrs intermixed with insect chirps and birdsong. “It's like a Garden of Eden,” wrote Daum, a research fellow at the University of Hohenheim in Germany studying agricultural development strategies. “Small robots could help conserve biodiversity and combat climate change in ways that were not possible before.” He…

Found in Robotics News & Content, with a score of 6.58

…operator to remotely command the lift truck to travel tractor-first in an aisle between picks, it said. The operator can remain on the floor in optimum picking position, minimizing travel to and from the lift truck. Raymond High Capacity Orderpicker. With an industry-leading elevated height of 456 in., the new High Capacity Orderpicker allows order picking a full rack higher than other current models, said Raymond. This gives operators access to 11% more pick slots and reducing annual cost per pallet stored by 19% compared with competitive models, it added. Built for use in e-commerce applications, the lithium-ion battery technology…

Found in Robotics News & Content, with a score of 6.30

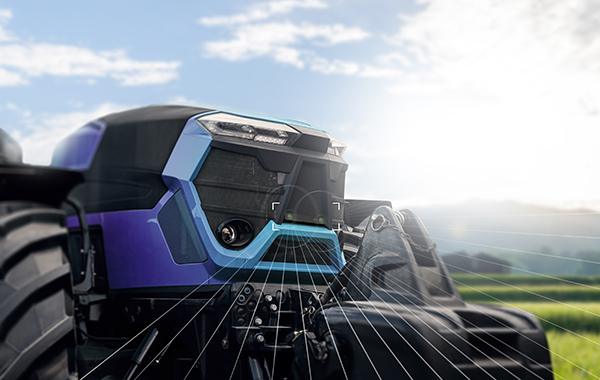

…detection during core process automation. For example, an autonomous tractor could use ZED-X for safe navigation, and ZED-X Mini for crop detection. Stereolabs also listed the following features: High-resolution RGB sensor with global shutter The ZED-X’s 1920x1200 global shutter RGB sensor produces imaging that accurately captures any action-filled environment, said Stereolabs. Moving scenes are rendered quickly up to 120 fps, it explained. The 3.0 µm pixel size guarantees image quality in both low-light and bright conditions, making the camera suitable for both indoor and outdoor applications. IMU designed for robots that experience high vibration The built-in inertial measurement unit (IMU)…

Found in Robotics News & Content, with a score of 6.30

…jacks, container handlers, automated guided vehicles (AGVs), and tow tractors. The unit also provides aerial work platforms, fleet management services, and advanced automation engineering and design. Toyota’s production system includes more than 230 locations across North America. The company said its dealers can help solve wide-ranging challenges in warehousing and distribution. Toyota said it has systems for applications including materials handling, energy, advanced logistics, and warehouse optimization. Toyota proposed that forklifts would be a perfect fit for such a learning studio and offered to donate the equipment and branding work necessary to bring the idea to life. Forklifts encompass all…

Found in Robotics News & Content, with a score of 6.07

…and Uber, which separately launched drone-powered deliveries and self-driving tractor trailers in recent months. UPS, FedEx’s main competitor, has also been publicly testing drone-powered parcel delivery since September 2016. Technavio analyst Bharath Kanniappan thinks that FedEx is falling behind its competitors in terms of implementing robots into its delivery system. However, he says, the company’s delay likely stems from a desire to ensure it can continue to deliver packages “with utmost care,” which he notes is the company’s “unique selling proposition,” given its reputation as an express shipper. Satish Jindel, who heads the transport and logistics consultancy SJ Consulting Group,…

Found in Robotics News & Content, with a score of 6.07

…vendor’s robots,” Christensen added. “For example, our Palion Tow Tractors are picking and placing at conveyors. Our AMRs can pull alongside the conveyor and transfer an item back and forth between the conveyor and the tow tractor.” “We also have AMRs currently integrating with roll-up doors in facilities so our robot can open the door as it enters a new space and then close it after it passes through,” he said. Berkshire Grey works to ensure reliability When it comes to pick-and-place applications, automation providers say system effectiveness comes as much from AI-based software as it does from the robot…

Found in Robotics News & Content, with a score of 5.73

…outdoors in an unpredictable environment, like autonomous mowers or tractors in the field, or where there’s a need to test potentially dangerous robots or vehicles during the development phase without putting their team members at risk.” “We also see situations where safe communications allow machines to operate faster—or even operate at all—when a human is in proximity, which drives machine ROI [return on investment] tremendously,” he said. Autonomy also raises a philosophical question, Reeves said. “Does society ever want smart machines to be out of the reach of a human operator, even if the machines are so smart that they…

Found in Robotics News & Content, with a score of 5.61

…the mechanization of agriculture in more developed countries. High-power tractors, combine harvesters, and other equipment are in widespread usage. Recent innovations that could level the playing field and effectively feed the world's more than 8 billion people include agriculture robots and artificial intelligence as part of Industry 4.0. These robots are primarily employed in activities that are repetitive in nature, thereby reducing the burden of manual labor on farmers. Agricultural industry leaders and automation innovators such as John Deere are developing robots that can not only replace backbreaking labor but also reduce waste and add insights for farmers. Here are…

Found in Robotics News & Content, with a score of 5.54

…LaFevers, Hyster. Source: LinkedIn For example, a robotic tow tractor can be used in a variety of time-intensive cart and product hauling duties, such as sequencing of parts, moving parts where they need to be when they need to be there to keep finely-tuned production lines moving. They can also be deployed for trash runs, collecting waste throughout the shop floor. Likewise, a robotic counterbalanced stacker can be used to automate common pickup and drop-off horizontal transport jobs, like picking up loads from elevated pallet conveyors on stretch wrapper and palletizing lines and then transporting them to outbound staging. Yale…

Found in Robotics News & Content, with a score of 5.49

…five things going on in the equipment behind the tractor, which is where most of the activity happens.” “Farmers are the ultimate multitaskers and micromanagers,” he added. The reality is that the typical farmer is managing lots of tasks. The load is significant, and windows of time are very compressed. They're spending 18 to 20 hours in a cab managing not only a dozen tasks at once, but also 70 million plants in a field.” “People do not realize that the number of people to do that work is going down all the time. There has been a 10% reduction…