Editors’ Picks

Found in Robotics News & Content, with a score of 15.82

…Mobile Robots Piece Picking Gets Faster With Robotic Perception Machine Tending and Welding With Robots More information about the sessions can be found at the event site. Unlike other robotics event, the first Robot Applications Conference will focus on robotics applications rather than individual technologies or market verticals. Speakers interested in participating in Robotics 24/7’s event can submit applications here. Please note that we are looking to speak to end users, analysts, and systems integrators. An attendee registration form will be up soon. Companies can learn more about sponsorship opportunities by contacting Tom Cooney at [email protected]. About Peerless Media Founded…

Found in Robotics News & Content, with a score of 21.96

The vast scope of robotics innovation is enabling machines to not only relieve humans of tedious tasks but also perform at superhuman levels. From picking operations in warehouses to complex surgical procedures, robots are becoming more dexterous and autonomous. And with artificial intelligence, they can operate more consistently and with fewer errors over time. Vision technology is enabling a host of new robotics applications. Robots and drones might be able to spot anomalies or defects, but they need contextual judgment to know what to do next. Similarly, can robotic vision discern aesthetically pleasing scenes and then snap a photo? That's…

Found in Robotics News & Content, with a score of 11.36

…50% reduction in parts, and it is suitable for machine tending, materials handling, and welding in addition to palletizing,” Beck explained. “We also designed a wider tool flange for the corresponding end effectors.” Universal Robots reaches for new applications Povlsen noted that global labor and skills shortages, as well as an estimated 22 million jobs with automatable tasks present a “real opportunity” for cobots, with only 2% penetration of the potential market. The UR20 will complement the existing e-Series cobots, and simulation tools are coming, according to Universal Robots. Potential users of the UR20 with UR+ certified URCaps applications include…

Found in Robotics News & Content, with a score of 12.31

…awareness is enabled by a synergy between sensors and machine learning. By giving mobile and picking robots more human-like perception of their physical environments, developers are also increasing the level of precision that users can expect from them. This in turn has expanded the range of tasks and services that robots can perform autonomously. “Robotics is often defined as an intelligent connection between sensing and acting,” said Sean Johnson, chief technology officer at Locus Robotics. “The sensor data is fed to algorithms that allow robots to actively map their working environments, recognize known objects as well as unknown obstacles, predict…

Found in Robotics News & Content, with a score of 18.53

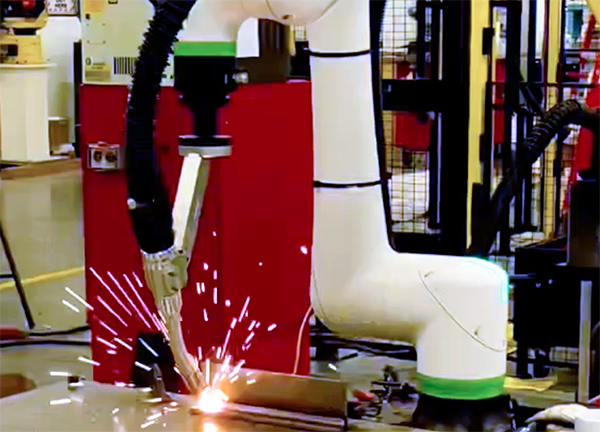

…tooling (EOAT) options, the CX1000 can be uncoupled from the weld cart and repurposed for different applications such as machine tending or sanding when not welding. The FastARC CX1000 cobot is equipped with a FANUC six-axis, 10-kg (22 lb.)-capacity cobot arm that Acieta said is maintenance-free for up to eight years. The system is compatible with Lincoln Electric and Miller Electric welders and is IP 67-rated with sealed components to work in industrial environments.

Found in Robotics News & Content, with a score of 18.80

…End users can configure multiple axes through Universal Robots' human-machine interface (HMI). They can simply set position, speed, and acceleration on the HMI or, with the URCap toolbar, move the axes in manual mode to configure motion. Festo said its multi-axis system features the Festo Motion Control Package (FMCP) for UR, which is a complete motion-control panel for up to four-axis motion. The FMCP is fully integrated with the UR cobot control panel and HMI and features a UR safety I/O and communications interface. Uses for more axes of motion In addition to a seventh axis used for linear transfer,…

Found in Robotics News & Content, with a score of 13.32

…U.S. partners, including assembly, specifically screwdriving, with Tool House; machine tending with Ellison; welding with MRO; and pick and place and palletizing with Tool House and RG. The company also showed 3D scanning for automotive inspection with Korean partner Hexagon Metrology. In a grinding and polishing demo, Doosan showed how a user could tilt a smartphone to control the angle of a robot. Designing a future with more robots Beyond its Automate exhibits, Doosan Robotics is working on more software-driven capabilities. It works with the Robot Operating System (ROS). The company said it is building on its suite with a…

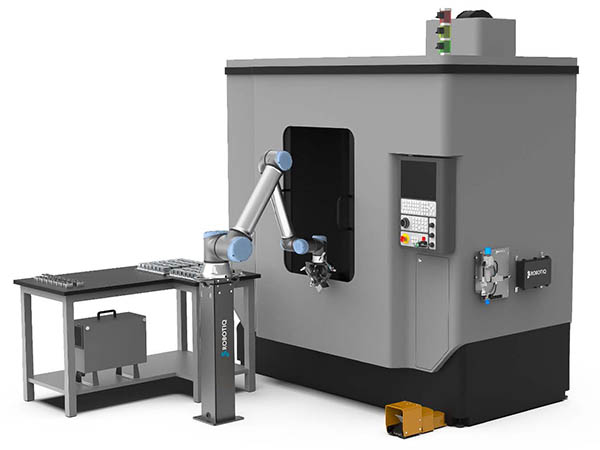

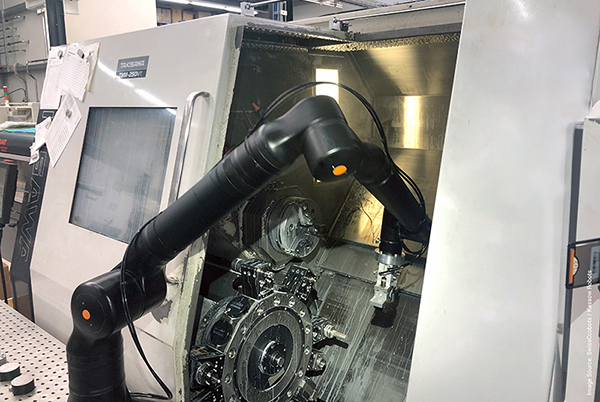

Found in Robotics News & Content, with a score of 66.79

…today said at Automate 2022 here that its new Machine Tending Application Solution will make collaborative robots more accessible than ever. The Lévis, Quebec-based company said its system can reduce implementation costs by up to 50% and takes less than two hours to go from unboxing to machining the first part—with no coding experience required. “When a machine shop owner struggles to find employees to do the work, their first instinct is to look for new CNC machines that can run unattended for longer and with shorter changeover times,” said Samuel Bouchard, CEO of Robotiq. “But those machines are costly,…

Found in Robotics News & Content, with a score of 23.61

DETROIT—Rapid Robotics Inc. said its Rapid Machine Operator is the first industrial robot that can get up and running in a matter of hours. Now, it’s also the first manufacturing robot that can move between jobs in less time than it takes to make a cup of coffee, said the company. Rapid Robotics said its Smart Setup feature enables anyone to move Rapid Machine Operators (RMOs) onto a new job in as little as 60 seconds using built-in computer vision. No programming or robotics expertise is required. “Smart Setup gives the Rapid Machine Operator human-like instincts about its surroundings and…

Found in Robotics News & Content, with a score of 24.35

…cell showing collision management ICONICS: supervisory control and data acquisition (SCADA) solutions including remote monitoring and incident management Absolute Machine Tools: automated machine tending, including ICONICS SCADA integration for remote monitoring Mitsubishi Electric Contact Image Censors (CIS): continuous scanning for quality control To learn more, visit Mitsubishi Electric Automation at Booth 1023 at Automate 2022, from June 6 to June 9. More than 20,000 attendees are expected to attend.

Found in Robotics News & Content, with a score of 22.59

…are perfect for limited-space retrofits and applications such as machine tending, pick-and-place tasks, quality inspection, and palletizing,” said Kassow. “No in-depth programming knowledge is required to operate the cobots, allowing small and medium-sized enterprises (SMEs) without robotics specialists to implement automation and programming cost-effectively and independently.” Founded in 2018, Kassow said it designs and manufactures lightweight industrial robots for “strong, fast, simple” tasks. The company claimed that its line of five seven-axis robots “offers a unique package of speed, power, and reach.” Bosch Rexroth became majority owner of Kassow Robots in April. Founder Kristian Kassow is now co-owner and continues…

Found in Robotics News & Content, with a score of 27.42

…robots are also useful for hard-to-staff tasks such as machine tending, dispensing, labeling, and screwdriving. “Our application diversity at this year’s Automate speaks volumes,” said Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots (UR). “Attendees visiting us and our partners at the show will have no issue finding a UR cobot automating the task they’re looking for.” Welding is a hot application for cobots Coming out of a record revenue quarter, Universal Robots said it is experiencing broad-based growth from many different segments including welding, an application area that grew 300% in 2021 in comparison…