Editors’ Picks

Found in Robotics News & Content, with a score of 2.89

…doing things smartly in their own manufacturing. Students can gain career, industry-defining skills What types of roles can Purdue students get with smart factory experience? Kumar: They'll find roles in three different types of companies. First are companies like Addverb that produce these technologies. Second, there are large companies like EPC [engineering, procurement, and construction] firms. Their don't only design one segment of a warehouse or a factory; they design entire projects. How do these technologies fit, and how do they interact? Third are the actual users of robots and automation: the automakers, consumer durables and appliance makers, FMCG, food,…

Found in Robotics News & Content, with a score of 4.09

…University. “The development of key infrastructure in the area of robotics will provide an important opportunity for students to gain practical experience in an evolving technology field that has massive potential in Advanced High-Volume Manufacturing,” he said. Editor's note: The article and headline have been updated with additonal information from Maynooth University.

Found in Robotics News & Content, with a score of 4.23

…authorization would provide it the foundation it needs to gain approval for other procedures in the future. The De Novo classification request process provides companies “a marketing pathway” to submit new medical devices through the FDA process. Through the process, the vendor must demonstrate the device provides “reasonable assurance of safety and effectiveness for the intended use,” according to the FDA's website. Virtual Incision CEO and President John Murphy told Robotics 24/7 that if the company clears the De Novo process, it will be able to go through a much shorter review process through the 510k approval pathway for future…

Found in Robotics News & Content, with a score of 3.33

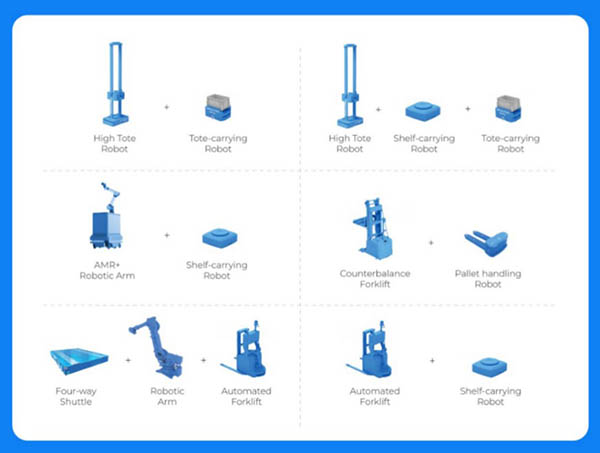

…robot fleet orchestration combination for your business and manage it through a single control system,” Wang added. “Expected productivity gains are available within days, alongside the flexibility to scale at your pace. Automation doesn’t need to be complicated!”

Found in Robotics News & Content, with a score of 1.42

…solutions Here’s a deeper look at each trend: Cobots gain muscle, keep simplicity A traditional strength of cobot arms is that they are relatively simple to deploy. The vendors in the cobot space often provide graphical, easy to use software for devising applications like end-of-line palletizing. They don’t require a costly enhancement of a facility’s electrical infrastructure, because many can run on standard 120-volt outlets, or 220-volt power. Moreover, cobots don’t need to be walled off by a fixed cage system, because they have safety sensing built in. The downsides of cobots have been payload and speed versus their larger…

Found in Robotics News & Content, with a score of 2.59

…ABB partnered with the company to take advantage of its vSLAM on its lineup of AMRs. “With vision, we gain higher-context information about the environment,” Cesari said. “This allows the system to run more robustly, especially when you look at the 3D space, not only for localization, but also for finding obstacles.”

Found in Robotics News & Content, with a score of 3.24

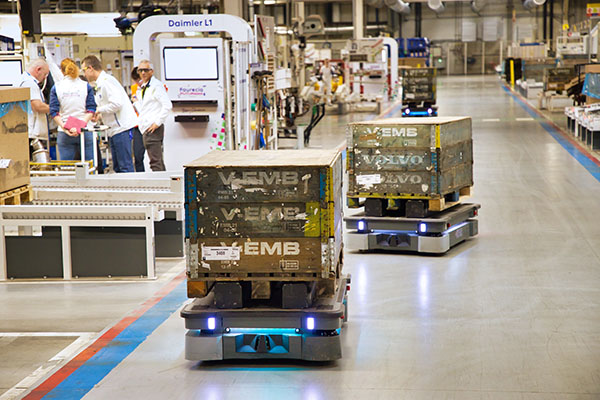

…a cloud-based software tool that enables fleet owners to manage and optimize the operations of its robots. They can gain actionable insights to improve the robots’ deployment, it said. “As robot fleets grow, so does the demand for software tools to optimize performance and manage full fleets,” Hathout said. “If we want AMRs to be as common as forklifts and pallet lifters, it is essential that we lower the barriers for implementation, reprogramming, and maintenance. We have already made substantial progress in this direction, and I firmly believe we have only glimpsed the true potential of automated logistic solutions.”

Found in Robotics News & Content, with a score of 1.71

…Industrial Internet with a path to significant operational efficiency gains,” said Tai-Yu Chou, chief technology officer at Foxconn Industrial Internet. “The combination of NVIDIA Metropolis for Factories and Isaac Sim for robotics is helping us realize industrial automation goals faster than ever imagined.” Innodisk is deploying NVIDIA Metropolis to automate inspection processes, saving cost and improving production efficiency. Techman Robot turns to Isaac Sim Quanta, a major manufacturer of laptops and other electronic hardware, is using AI robots from its Techman Robot subsidiary to inspect the quality of manufactured products. Taiwan-based Techman is simulating, testing, and optimizing its collaborative robots…

Found in Robotics News & Content, with a score of 5.46

…to cut the production cost by approximately 50% and gain a significant price advantage over its competitors. The company has been gearing up to expand its presence in North America for quite some time, and said it recently obtained all the necessary certifications to begin selling in U.S. and Canada. Rainbow Robotics has been awarded the US NRTL and CSA (Canadian Standards Association) certifications by the global certification body TÜV SÜD. (CSA Z434:2014, UL 1740:2018/R:2020-11, NFPA79:2021) In addition to looking to bring on new customers, Rainbow Robotics said it is hoping to attract potential employees at the show. Rainbow Robotics…

Found in Robotics News & Content, with a score of 2.33

Collaborative robot arms can gain more axes of motion, making them useful for new applications. Festo Corp. yesterday announced that it will show its UR+-certified multi-axis system at Automate 2023 next week in Detroit. The company said it adds up to four axes beyond the six axes of Universal Robots' cobots. Islandia, N.Y.-based Festo said its multi-axis system features the Festo Motion Control Package (FMCP-UR), which is a complete motion-control panel for up to four axes. The FMCP is fully integrated with the UR cobot control panel and human-machine interface (HMI), and it includes an enhanced safety I/O handshake and…

Found in Robotics News & Content, with a score of 3.76

…support call with Vention, the customer success team will gain full awareness of the machine, from the hardware and firmware versions and the real-time I/O state to the program running on Vention’s MachineMotion controller. This ensures that user guidance will be efficient and timely, said the company. Vention claimed that its customer success team provides above 96% in terms of responses within the promised time. With more than 16,000 equipment pieces already deployed, the company asserted that it consistently achieves a net promoter score above 75. Vention cited the following features and technical advancements in Pendant V3 that will allow…

Found in Robotics News & Content, with a score of 4.86

…helping them to drive significant operational efficiency and productivity gains, and deliver a faster time to value.” Wilmington, Mass.-based Locus Robotics said its AMRs collaborate with human workers to dramatically improve product movement and order-fulfillment productivity. The company said its hardware and software can also reduce operational costs and improve workplace ergonomics. Locus said that more than 100 of the world's top brands, retailers, third-party logistics providers (3PLs), and specialty warehouses have deployed its award-winning systems at over 250 sites. It recently announced that DHL Supply Chain will deploy 5,000 Origin robots across multiple sites. At Automate 2023 in Detroit…