Editors’ Picks

Found in Robotics White Papers & Archives, with a score of 1.63

…drones, adoption of autonomous systems is steadily increasing. The COVID-19 pandemic and subsequent supply chain challenges and exacerbated labor shortages are driving interest. All of these technologies depend on complex hardware and machine learning to maneuver through dynamic environments, handle a wider variety of items, and interact with humans. Developers can now take advantage of more efficient sensors and novel materials for soft robots to solve real-world problems. In addition, robots are specializing, becoming more dexterous and nimbler or more rugged as needed. Overcome constraints with SBCs But constraints remain, such as compute power, energy efficiency, and total system expense.…

Found in Robotics News & Content, with a score of 1.62

…ago, but our expansion plans were affected by the COVID-19 pandemic,” said Mathan Muthupillai, CEO of Techmetics Robotics. “But we were not sitting idle. We focused on new product developments and advanced the mobile platform development schedule.” “In addition to mobile platforms, we developed a UV disinfection robot and the high-security delivery robot or SDR,” he told Robotics 24/7. “We also enhanced all our existing solutions, like Butler and Concierge for contactless delivery.” All about the base The company said it uses safety-compliant SICK sensors and safety controllers. The TRV line also comes with a braking system on the drives…

Found in Robotics News & Content, with a score of 1.61

…of mobile robots is in part because of the COVID-19 pandemic, labor shortages, and the acceleration of online ordering, said Ash Sharma, managing director at Interact Analysis and author of the report. Because more companies are choosing to automate, “this has caused sales in mobile robots to spiral, with nearly 70% more vehicles shipped than the year before and a 36% increase in revenues, which rose to nearly $3 billion,” he wrote. “It is reguarly claimed that robots will steal jobs from people,” Sharma added. “But in a post-COVID world, we are seeing the opposite: Robots are filling gaps left…

Found in Robotics News & Content, with a score of 1.59

…is still a large untapped industry worth, according to Quicktron. Growth in this sector has also accelerated as the COVID-19 pandemic has fueled the need to reduce reliance on manual labor in logistics In today’s announcement regarding the C+ funding, Quicktron didn’t state the dollar amount of the funding round.

Found in Robotics News & Content, with a score of 1.59

…millions of face shields available in the fight against COVID-19. Fictiv has invested in the upfront tooling costs to make the shields available as quickly and easily as possible to healthcare agencies, service providers, distributors and even non-healthcare OEMs that are pivoting to support the healthcare industry during this crisis. The pricing will be matched to cost, and additionally, any longer-term profits beyond initial tooling and unit manufacturing costs will be donated to the COVID-19 Solidarity Response Fund for WHO. The shield is based on open-source face shield designs, similar to the visor recommended by the National Institutes of Health…

Found in Robotics News & Content, with a score of 1.58

Hospitals are in need of mechanical ventilators to treat COVID-19 patients. In response to this shortage, Materialise has developed the Materialise NIP Connector, a device to convert standard equipment available in most hospitals, into a mask to facilitate breathing for patients by creating positive pressure in the lungs. These assembled masks allow clinicians to reduce the time patients need access to mechanical ventilators, which helps to reduce the strain on ventilator supplies. Materialise is now fast-tracking the regulatory registrations that are crucial to ensure the safety of patients and caregivers. The company expects to have the device broadly available for…

Found in Robotics News & Content, with a score of 1.57

…we are out of the woods. The toll the COVID-19 pandemic is taking on our supply chains will only continue to inflict pain on our global supply chain and contribute to the current logjam well into 2023. As more variants spread, major ports will be forced to shut down and contribute to the ever-growing delays. The third-busiest port in the world, China’s Ningbo-Zhoushan, was forced to shut down in August upon the discovery of a single COVID-19 case. China’s “zero tolerance” approach to the pandemic has continued to exacerbate already stretched supply networks. This closure quickly led to record breaking…

Found in Robotics News & Content, with a score of 1.54

…designed to be used effectively and immediately during the COVID-19 pandemic, said AIS. “Despite the unprecedented challenges of the COVID-19 pandemic, B.C.’s tech community has continued to find solutions and turn obstacles into opportunities,” said Riaz Meghji, TIA’s co-host and author of Every Conversation Counts. “The past year has shown that when faced with an obstacle, B.C.’s tech sector rises to the challenge and comes out stronger.” “The future of our province’s tech industry relies on our ability to be fluid and adaptable to changing conditions and to use our capabilities to quickly pivot into developing the required solutions for…

Found in Robotics News & Content, with a score of 1.51

…as a future trend in the industry. Since the COVID-19 pandemic, there has been a surge in online shopping across the world. E-commerce sales have witnessed a significant growth rate over recent years. According to the International Air Transport Association (IATA), in 2021, 2.14 billion people (i.e., 27.6% of the world’s population) shopped for products from online portals. The growing demand for online shopping is pushing companies to perform faster picking and placement operations, which is raising the demand for packaging robots, the report says. In the e-commerce industry, picking robots are used for order fulfillment as manually picking of…

Found in Robotics News & Content, with a score of 1.45

…order to meet huge spikes in demand due to COVID-19. The AMRs now provide the leading retailer with the ability to pick an additional 2,000 orders per hour and add a further 20,000 stock-keeping-units (SKUs) to its original 80,000. These capabilities played a major role in the e-commerce leader being able to grapple with its busiest-ever peak period on record last year. Previously the retailer had invested in traditional large-scale automation, which was serving Catch Group quite well until COVID-19 forced the entire country to shop online – driving a dramatic shift in consumer behaviour. Two of the most common…

Found in Robotics News & Content, with a score of 1.43

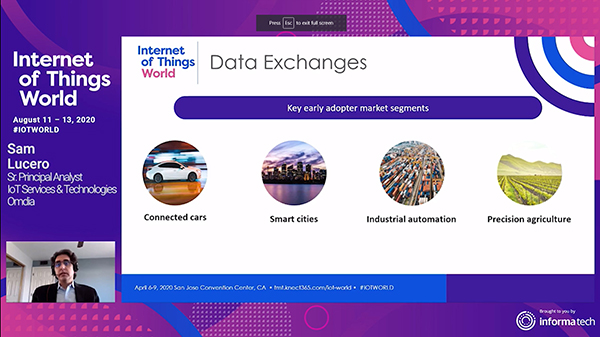

…online, kicking off this week. The looming threat of COVID-19 and its widespread impact are reflected in the show's content lineup. Sam Lucero, Sr. Principle Analyst, IoT Services & Technologies, Omdia, said the impact of COVID 19 on IoT is complex, but not all bad. He characterized the nature of the projects as “more of a delay than derailment.” On the bright side, “the virus situation demonstrates the value of connected solutions in new areas.” In the opening keynote on August 11, Zack Butler, Informa Tech, Portfolio Director, shared results from a result survey. “It's really encouraging to see that…

Found in Robotics News & Content, with a score of 1.43

…Fla., area who were unemployed or displaced during the COVID-19 pandemic. The “Connecting Talent to Careers Project” is intended to create a comprehensive national capability for talent identification and attraction for manufacturers nationwide. The ARM Institute is leading the project, which is receiving $2.997 million from the Labor Department’s National Dislocated Worker Grant and $650,000 in non-federal funds. “The COVID-19 pandemic hit manufacturers in an unexpected and unprecedented way in 2020 and 2021,” stated Lisa Masciantonio, chief workforce officer at the ARM Institute. “These disruptions revealed critical vulnerabilities in American supply chains, highlighted the benefits of innovative technologies that enhance…