Editors’ Picks

In a new “manufacturing outlook” report focusing on the automotive and industrial sectors, AlixPartners observes that many of the labor-cost advantages associated with near-shoring may be lost if companies fail to spend more on automation in the future. The consultancy notes that automation capabilities have improved dramatically, and implementation expenses have come down. As a consequence this kind of technology can help manufacturers augment—or entirely replace— functions previously performed entirely by humans. “To exploit those technologies, manufacturers will likely have to make capital-intensive investments,” says Foster Finley, a managing director at AlixPartners in New York. “But they should understand, too,…

When it absolutely, positively has to be there overnight, your FedEx package might someday be delivered by a robot. Rob Carter, FedEx’s chief information officer, says the shipping giant is considering small vehicles that could drive around neighborhoods and make deliveries without human drivers. Carter is responsible for setting the technology agenda across FedEx’s various operating companies, including its planes-and-trucks Express shipping service and office-and-home Ground delivery service, which operate in 220 countries. He recently told MIT Technology Review about some of FedEx’s emerging technology initiatives in artificial intelligence and robotics. The investments FedEx makes in these technologies could shape…

Editor’s Note: The following column by Jim Lawton, chief product and marketing officer, Rethink Robotics, is part of Modern’s Other Voices column. The series features ideas, opinions and insights from end-users, analysts, systems integrators and OEMs. Click here to learn about submitting a column for consideration. ——— Change is inevitable. In manufacturing and distribution, we’re at a pivotal point, where technology and process intersect to drive wholesale change in the way things get done. Broadly captured by the moniker “Industry 4.0”, this era will be built on information-driven operations that optimize efficiency, capacity and innovation. It won’t happen overnight. It…

Wasion Group is a manufacturer of smart metering, smart power distribution and energy management in China and international markets. The company produces 35 million units of various equipment annually, including many products in lower volumes. After deploying collaborative robots, (Rethink Robotics), the company has optimized production to meet changing market demands and expedite delivery. The new robot was first used on an assembly line for manufacturing single-phase energy meters. They are now used at multiple workstations including loading electric meter boxes, PCBA loading and assembling, power testing and code scanning, and carrier loading and assembly. The robot features compliant motion…

In a new “manufacturing outlook” report focusing on the automotive and industrial sectors, AlixPartners observes that many of the labor-cost advantages associated with near-shoring may be lost if companies fail to spend more on automation in the near future. The consultancy notes that automation capabilities have improved dramatically, and implementation expenses have come down. As a consequence this kind of technology can help manufacturers augment - or entirely replace - functions previously performed entirely by humans. “To exploit those technologies, manufacturers will likely have to make capital-intensive investments,” says Foster Finley, a managing director at AlixPartners in New York. “But…

As seen in recent headlines, major companies like Kellogg Co., UPS and Google are executing large sustainable and “green” goals not only to benefit the company’s bottom line, but to accommodate consumers. An online study by Nielsen found that three-out-of-four millennials are willing to pay extra for sustainable products. Companies that market their sustainability practices are more likely to build brand reputation and grow loyalty among younger consumers. Three popular ways to “go green” in the workplace are to reduce carbon emissions, purchase green products, and implement automation into your warehouse. Adding automation, like an automated storage and retrieval system…

With high consumer demands comes more product and increased sales, resulting in growth. Growth is great, but where do you put all of the new product being produced and how do you get it to your customers quickly? In a recent study conducted by Peerless Media, it was confirmed that most of the respondents are indeed experiencing growth in their companies. Respondents also made it clear that their two largest issues were with insufficient space and outdated storage, picking or materials handling equipment. Aaron Corcoran, account executive at Westfalia, and guest speaker Dave Williams, director of software and solution delivery…

The Association for Advancing Automation (A3), a leading global advocate for the benefits of automating, has announced a call for startup companies in robotics, machine vision and motion control to enter the Automate Launch Pad Competition. The competition is a chance for the industry’s most innovative young companies to vie for the spotlight at the Automate 2017 Exhibition and Conference—the industry’s largest gathering in North America, taking place in Chicago, Ill., April 3-6, 2017—as well as a $10,000 cash award. The Automate Launch Pad Startup Competition seeks out startup companies looking to generate awareness of their technology and find new…

The Association for Advancing Automation (A3), a leading global advocate for the benefits of automating, has announced it is forming a not-for-profit trade association specifically dedicated to supporting and promoting the rapidly growing Mexican automation industry. With the world’s 11th largest economy, Mexico is home to a vast array of industries including substantial automotive and aerospace manufacturing sectors. According to A3, in 2015 industry-wide sales of robots in Mexico almost tripled to 6,320 units, exceeding $243 million. A3 is embracing Mexico’s broad-based growth and potential by forming a new association, A3 Mexico, focused on this expanding market. A3 is the…

As the dream of autonomous cars edges closer to reality, automatic guided vehicles (AGVs) are advancing into the warehouse in a very real way. As the likes of Google and Apple pour resources into the development of driverless technology, the decreased price and improved performance of the vehicles are benefiting the makers of driverless industrial vehicles. Already, Amazon is poised to become one of the biggest users—and suppliers—of automatic guided vehicles in the warehousing and distribution space. But AGVs aren’t just for those with big budgets and massive operations. In fact, AGVs aren’t even always AGVs. The “guided” part of…

Often, the number of orders that need to be fulfilled per day dictates the degree of automation required. Regardless of your DC's specific requirements and throughput rates, the right sortation automation solution helps enable the process efficiencies needed to meet rising service level agreements. From receiving and put-away to picking and packing, sortation technology plays a role in nearly every aspect of DC operations. Sortation Automation In Intelligrated's next On The Move webinar, titled “Sort it out! Making smart sortation automation decisions,” Satyen Pathak, senior product manager, will discuss the full range of sortation automation solutions that are available for…

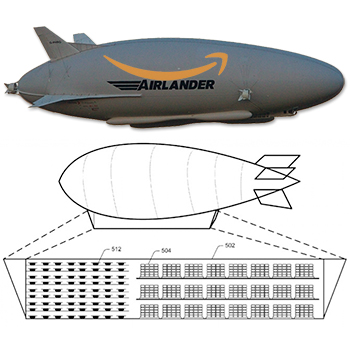

Amazon has been working on getting a drone delivery program off the ground for a while now, but some new patents show the company isn't out of wild ideas. As TechCrunch reports, Zoe Leavitt, an analyst for CB Insights, has discovered a recent Amazon patent for an “airborne fulfillment center utilizing unmanned aerial vehicles for item delivery” - i.e., a giant flying drone mothership zeppelin warehouse. The patent envisions the airborne fulfillment center (AFC) in the form of a giant airship, that would fly at high altitudes of around 45,000 feet in the air, and would then deploy individual drones…