Editors’ Picks

As reported by The Verge, Kitty Hawk is the “flying car” company that’s financially backed by Google founder Larry Page, and today it has published the first video of its prototype aircraft (see video above). The company describes the Kitty Hawk Flyer as an “all-electric aircraft” that is designed to operate over water and doesn’t require a pilot’s license to fly. Kitty Hawk promises people will be able to learn to fly the Flyer “in minutes.” A consumer version will be available by the end of this year, the company says. The video is part commercial and part test footage,…

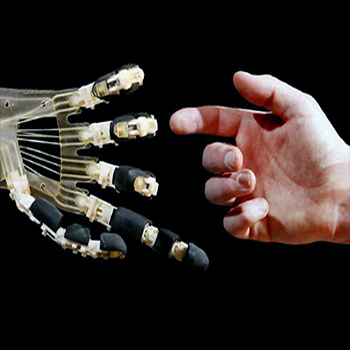

The human hand is a wondrous device. The complexity of its design is such that even the most advanced grippers pale in comparison. It does have its shortcomings, mainly in strength, stamina, and durability. But the range of tasks it can accomplish is staggering. What makes the hand even greater is its connection to the eyes. Your arm and hand are not programmed to take one static path to grab something. Hand eye coordination enables an infinite number of moves. Consider the difference between these five tasks: Pick that up from that place. Pick any of these objects from those…

Amazon was awarded a patent yesterday for an on-demand manufacturing system designed to quickly produce clothing - and other products - only after a customer order is placed. The computerized system would include textile printers, cutters and an assembly line, as well as cameras designed to snap images of garments that would provide feedback on alterations needed in subsequent items. In order to increase efficiency, the goods would be manufactured in batches based on factors such as the customer shipping address, the patent says. Once various textile products are printed, cut and assembled according to the orders, they can be…

Recent developments in robotics, artificial intelligence, and machine learning have put us on the cusp of a new automation age. Robots and computers can not only perform a range of routine physical work activities better and more cheaply than humans. But they are also increasingly capable of accomplishing activities that include cognitive capabilities once considered too difficult to automate successfully, such as making tacit judgments, sensing emotion, or even driving. Automation will change the daily work activities of everyone, from miners and landscapers to commercial bankers, fashion designers, welders, and CEOs. But how quickly will these automation technologies become a…

Clockspeed. If you’re not familiar with the term, it was coined by Charles Fine, an MIT professor, to define rapidly evolving industries – those with a fast clock speed that he likened to fruit flies that are born, mature and expire in a very short time. He argued that “in business today, all advantage is temporary. In order to survive-let alone thrive-companies must be able to anticipate and adapt to change, or face rapid, brutal extinction.“ Based on my week at Promat in Chicago, I’d argue that the clockspeed of our industry has been accelerating in an unprecedented fashion over…

Automation and robotics is already changing the US workplace, and by 2027, we could be looking at dramatically different numbers each month when the Bureau of Labor Statistics releases its non-farm payroll data. Forrester predicts 10 million jobs will be lost as a direct result of the robotic revolution. While the shift will come with a new wave of hiring (it estimates 15 million), automation and robotics will eliminate 25 million. Put another way: one new job will be created for every 15 lost. So how might the NFP jobs report look years from now? Take the number of retail…

Locus Robotics

DHL Supply Chain, an Americas' leader in contract logistics and part of Deutsche Post DHL Group, announced that it will begin a pilot test using a collaborative, autonomous robotics solution within the life sciences sector at a facility in Tennessee in the next two months. The robots, called LocusBots from Locus Robotics, are being tested as a picker companion for piece picking order fulfillment in the warehouse. LocusBots work collaboratively and safely alongside warehouse staff, helping to quickly locate and transport pick items, so pickers don't have to push carts or carry bins. “We believe it's critical to identify and…

Automation has become one of the major ongoing stories regarding the future of the American economy. What began with the rise of robots - and loss of jobs - across manufacturing industries is now a full blown threat to traditional jobs across all industries, salary bands, and education requirements. The effects are wide-reaching, no job may be safe. On the surface, trucking seems to fit perfectly into this national narrative. Autonomous vehicles are one of the hottest developments in technology across the country, and an automated truck already delivered 50,000 cans of beer within Colorado last fall. Meanwhile, truckers hold…

RightHand Robotics (Booth S1891) is demonstrating RightPick, a combined hardware and software solution that handles the key task of picking individual items or “piece-picking.” With RightPick, businesses can reduce the cost and improve the reliability of e-commerce order fulfillment for pharmaceuticals, electronics, grocery, apparel and countless other industries. As e-commerce continues to grow, the trend is away from bulk or pallet-load handling toward single SKUs and piecemeal items. Unlike traditional factory robots, RightPick handles thousands of different items using a machine learning backend coupled with a sensorized robot hand that works in concert with all industry-leading robotic arms. “The supply…

The new Dispen-SI-matic A-Frame dispenses inventory into variable-sized shipping containers common to omni-channel, said Ed Romaine, VP of sales and marketing for SI Systems (Booth S5418), in a press conference on Tuesday. “The benefits of robotic order picking are here today with this machine,” he said. “It can pick up to 2,200 orders per hour—that’s orders, not lines—directly into various size shippers while eliminating all picking labor.” The A-Frame has channels on each side that hold one stock-keeping unit (SKU) apiece and dispense up to five items per second. Orders, separated by as little as 1-inch of space, are processed…

A pocket sorter integrated with vision-system guided robotic picking and a streamlined conveyor system were showcased by Kevin Reader, director of business development and marketing at Knapp Logistics Automation (Booth S1223), in a Monday press conference. “The vision system has been recently updated,” he explained. “It evaluates the stock keeping units (SKUs) in the totes as they travel along the conveyor, directing the robotic gripper to properly pick up the required SKU. Additionally, the robotic component is faster.” The pocket sorter and robotic picking system are among several Knapp technologies targeting the challenges faced by e-commerce, multi-channel and omni-channel retailers,…