Editors’ Picks

Found in Robotics News & Content, with a score of 1.37

…like AutoStore bots move totes to optimize access to inventory, although perhaps not as often. What’s more, the software and technology operating the farm was designed in house and custom built for Bowery Farming, including the ASRS and conveyor system. To make that happen, the company invested heavily in talent: Frankert, for instance, previously worked at SoftBank Robotics, where he focused on technologies for micro-fulfillment centers in the 7,500 to 10,000 square foot range. Pallets of plants are moved by conveyor into the main grow area. Source: Jeff Fusco/Getty Images for Peerless Media. Optimizing automation According to Frankert, who joined…

Found in Robotics News & Content, with a score of 1.37

…Mitchell noted that automation has evolved from workflows and inventory to trying to augment an operation's most skilled workers. Although ChatGPT is getting a lot of hype, generative AI could be used to design more efficient hardware, Liu added. Improving connections between the office and the field for quality control is another worthy goal, said Leung. “After 20 years, we're still looking for computers that can read 2D floor plans,” she said. “We're still looking for robots that can serve big pain points, and we want to see more startups partner with industry and groups like MassRobotics. Get feedback on…

Found in Robotics News & Content, with a score of 1.35

…danger height.” “These functions protect your people, other trucks, inventory and other equipment like racking” Hess added. “They can help improve safety, and also productivity, because it gives the operators a high degree of confidence.” Another advancement, Hess pointed out, is Yale’s “Operator Sensing System” on the floor of some of its newer models, which uses lasers to detect the presence of the operator. These optical sensors do away with the traditional “dead-man” pedals on the floor, allowing the operator freedom of movement. Automation helps DCs face order deluge The cumulative effect of such features is that operators are fresher,…

Found in Robotics News & Content, with a score of 1.35

…you need to know the materials you have in inventory, how long will it take you to order the materials or the tools you need to make it; and also, what [does] the current production pipeline in your factory look like.” Being an independent operator, Plethora has access to such insider data and can respond to quotes more accurately, Mitchell notes. Technically, nothing prevents Plethora from joining a buyer-supplier matchmaking site or a vendor-run network. But Mitchell says the company so far hasn’t felt the need. “We feel going to Plethora directly is a better experience than going to Plethora…

Found in Robotics News & Content, with a score of 1.34

…(RMS) capable of managing the robots, certain elements of inventory, and the people working around the robots. Whether fed by a WMS or a simple spreadsheet, the system can facilitate picking, consolidation and delivery of single- or multi-line orders, especially if the AGV is equipped with a manipulator that lets it pick independently of a human. “For example, consider an e-commerce operation with hundreds of thousands of SKUs. A robot might only be able to pick 50% to 60%, but it can bring a tote of items to a person,” Elazary explains. “It’s a goods-to-person setup that uses existing shelving…

Found in Robotics News & Content, with a score of 1.32

…challenges, interest has risen in micro-fulfillment centers and bringing inventory closer to consumers. How can robots enable this? Dryer: Robots are integral. Using mobile robots integrated with lifts for case and tote storage and retrieval on traditional racking—this approach is very open-ended and flexible. It allows for scaling, and there's no single point of failure. It's ideal for customers that don’t want to make massive upfront investment but want to scale. There's also picking with configured ASRS and micro-fulfillment systems, combined with other automation for fulfillment out to the shipping operation. There are a lot of opportunities in that whole…

Found in Robotics News & Content, with a score of 1.31

…managing waves, or managing some of the movement of inventory and people.” Also down were a few indications on spending on mobile computing solutions. In this section of the survey, 54% are using or have plans for mobile technologies, which is down from 62% in 2017, though close to the 57% for this question in 2016 and 2015. However, when asked earlier in the survey about bar coding and automated data capture, 48% have plans for these functions in 2018, up by 3% from 2017. Under the mobile computing section, respondents indicate growing interest in some of the newer technologies.…

Found in Robotics News & Content, with a score of 1.26

…infrastructure. Mobile robotics/smart AGVs that can carry or pull inventory to workstations—or function as smart, driverless lift trucks—would alleviate the labor needs at the DC level, and allow for DC automation that’s quicker to install and reconfigure. “There has always been this tradeoff with traditional automation in that while it can lower operating costs over the long term, it tends to be costly to acquire and involves a long time to install, implement or change,” says Klappich. “Where we are at now is that smart AGVs/robotics are beginning to break that traditional tradeoffs between efficiency and agility, and that situation…

Found in Robotics News & Content, with a score of 1.26

…and how it will interact with other systems and inventory. “We’ve become experts in modeling robotic system deployments and building simulations to accurately model return on investment for our customers,” he says. The relatively rapid deployment timeframe of newer technology like AMRs acts to lower risk, agrees Sidell, but end user companies should take care to vet startups, assess the fit of the technology to functional gaps, and also craft aspects like service levels and support into agreements. But speed and flexibility of most of this startup technology goes a long way to reducing risk. As Sidell notes: “If I’ve…

Found in Robotics News & Content, with a score of 1.25

…code scanning to track activities and the location of inventory in the warehouse. Mobile assets, such as forklifts, automatic guided vehicles, robots, manual operators, or even a person walking through the facility are outfitted with sensors or wearable devices that communicate their location in real-time to within 10 centimeters across X, Y, and Z-axis. The system is sensitive enough to know whether an associate is standing up or laying down. With that level of accuracy, “the system knows the relationship of every tag in the facility,” said Bengt Tuner, Locanis’ president, and CEO. “You can create geofencing around people and…

Found in Robotics News & Content, with a score of 1.24

…relationships such as the aisles and the locations of inventory in shelves and racks. What it doesn’t know is distance, traffic congestion and the current status of people on the floor. “We can look at traffic and congestion for more efficient path planning when we get a wave of orders,” Nasser says. “This is a level of real-time data that isn’t visible to the WMS.” Nasser thinks of this data sharing as “closing the loop” between the robotic system and the WMS. In another example, Fetch robots are scanning RFID tags throughout the warehouse to create a visual map of…

Found in Robotics News & Content, with a score of 1.23

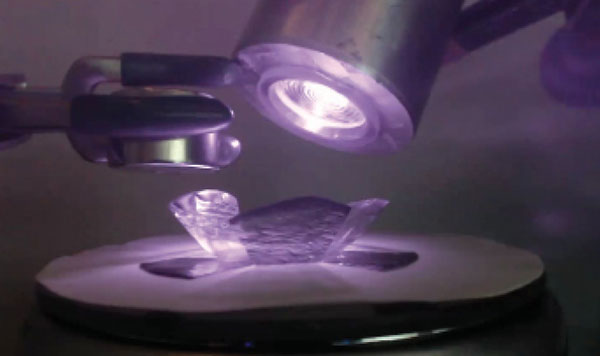

…can address these issues. The process of developing an inventory of materials that can bring soft robotics to their full potential, however, has its own challenges. One of the greatest of these is that developers have yet to fully analyze the materials being used. Developers must attain a better understanding of the materials in use before optimizing for soft robot construction. Another obstacle is the nonlinearity of soft materials. “Because soft materials do not behave linearly to applied forces, unlike hard materials, new design and testing tools need to be developed to analyze soft materials,” says Rothemund. “In addition, soft…