Editors’ Picks

Found in Robotics News & Content, with a score of 7.15

…unique architects, geometries and capabilities.” The multi-material DragonFly Pro precision additive manufacturing system allows electronics designers and electrical engineers to 3D print conductive metal and dielectric polymer simultaneously, for in-house prototyping and small batch production. With the need for electronics, automotive, defense, consumer, and medical device manufacturers to provide a wide range of electronic components, the ability to prototype 3D printed circuit boards in just hours onsite enables rapid innovation and time-savings, regardless of a circuit’s complexity. Nano Dimension’s DragonFly Pro system provides unlimited possibilities for creating the densely packed electronic prototypes required for smart design iteration such as sensors,…

Found in Robotics News & Content, with a score of 2.31

…that learns from past condition monitoring. The goal is high-precision predictions of machine performance and efficiency that pinpoint specific maintenance needs in real time. “We’re enabling this through a proprietary Cloud platform called the Digital Vault. It is helping connect diverse building systems and creates insights for buildings and occupants,” says Sinha. Blockchain: IBM There are plenty of ways for the electronic parts supply chain to be compromised. One is the loss of visibility as parts move through the supply chain. This could lead to the replacement of genuine parts with counterfeits. And then there is the problem of disputes…

Found in Robotics News & Content, with a score of 8.84

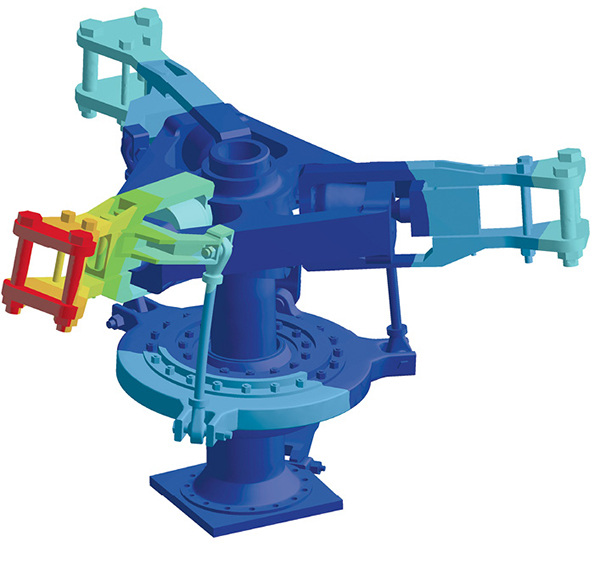

…RenAM 500Q metal additive manufacturing machines to Knust-Godwin, a precision machining company located in Katy, TX. The high-productivity machine, designed for serialized industrial manufacturing, helps Knust-Godwin to reduce lead times for its customers. Knust-Godwin has history of machining large, complex parts for oilfield instrumentation. The company first introduced additive manufacturing as a new technology to help improve the efficiency and productivity of tools in the oil and gas industry. The company chose to expand its additive manufacturing (AM) capacity to handle serial production, purchasing four RenAM 500Q machines. “Additive manufacturing started as a prototyping technology, but it is now moving…

Found in Robotics News & Content, with a score of 8.00

…efficient variable-geometry propulsion system. XB-1 has functional, performance, and precision requirements, so Boom turned to VELO3D to leverage its deep market expertise and customer support partnership. VELO3D’s Intelligent Fusion technology provides a level of control, design freedom, and quality assurance that is critical in challenging design environments such as supersonic aircraft performance. With VELO3D, Boom hopes to use metal additive manufacturing to accelerate aircraft development and improve system performance. “High-speed air travel relies on technology that is proven to be safe, reliable, and efficient, and by partnering with VELO3D we’re aligning ourselves with a leader in additive manufacturing that will…

Found in Robotics News & Content, with a score of 8.53

…2019 Hexagon, a company with roots in metrology and precision measurement technologies, recently hosted the annual user conference, HxGN Live (June 15-18, Las Vegas, Nevada). Over the last decade, the company has steadily expanded through growth and acquisitions into simulation, autonomous vehicles, location-based intelligence, and manufacturing, among others. One of the most popular demos on the show floor is the Birdly, a VR flight simulator. It lets you strap on to a set of artificial wings and fly through a virtual 3D city. The faster you flap your wings, the faster you fly. You can perform deep dives and sharp…

Found in Robotics News & Content, with a score of 5.01

…“For multi-rotor it makes sense, because you don’t need precision but we need to produce the prototypes fast,” Kayacan continues. “We’re very happy with it in that case. I design something, we put the CAD model into the 3D printer, go home, and when we come to eh office the next day the part is ready.” Simulation and Data In May, the research term published a paper, “An Intelligent Hybrid Artificial Neural Network-Based Approach for Control of Aerial Robots,” in the Journal of Intelligent & Robotic Systems. It outlines a proposed hybrid control approach that would use AI to enhance…

Found in Robotics News & Content, with a score of 3.11

…sourcing (i.e., conflict minerals tracking), contract labor management and precision logistics. He pointed to algorithms and a new data model as the engines that are making these trusted transactions happen, and noted that “most companies don’t know what algorithms they have and are not managing them as strategic assets.” Up next, George Bailey of the Digital Supply Chain Institute explained how today’s supply chains are operating under extreme margin pressure and being asked to do more with less. When it comes to technology adoption, he said that transformation is needed on a massive scale. “Most companies are not galloping,” Bailey…

Found in Robotics News & Content, with a score of 7.02

…connectors, right up to cargo aircraft, with metrology grade precision,” says Artyom Yukhin, president and CEO of Artec 3D. “In addition, all of our new software features lead to a more intuitive user experience for users in every industry, from quality inspection to CGI and 3D printing.” With Studio 14, users of Artec Ray can now perform fast, geometry-only Global Registration. Users also have the option of performing hybrid registration by using geometry and 2D targets. These features all equate to registering and processing scans easier and faster, according to the company. When exporting files to SolidWorks or other CAD/CAM…

Found in Robotics News & Content, with a score of 2.93

…used. Additionally, their fixed reliance on triangles limits the precision of the workflow model and the output quality.” “GPUs are fast but lack the infrastructure to do geometry,” says Shawn Hopwood, Dyndrite chief marketing officer. “There needs [to be] something on top of the kernel.” Thanks to NVIDIA’s Maxwell generation of GPU technology, Hopwood says Dyndrite can run a full geometry kernel on top of the GPU. “What we see [in 3D processing] is what happened in 2D when Adobe created PostScript,” adds Hopwood. “Computing has gotten to the level where we can operate and compute what goes to the…

Found in Robotics News & Content, with a score of 4.10

…collaborates with Nikon, a supplier of advanced opto-electronics and precision technologies, to improve insight into the 3D printing build process. These research activities, supported by Materialise software and the Materialise Control Platform, aim to provide users more control and increase productivity through analysis of the building process. Materialise and Essentium, a provider of 3D printing solutions for industrial additive manufacturing, entered into a strategic partnership in November 2018 to jointly advance and scale industrial 3D printing. In a first step towards that goal, the companies have announced the integration of Materialise’s Magics Essentials software with the Essentium High Speed Extrusion…

Found in Robotics News & Content, with a score of 10.23

…productivity. With SICK’s patented outdoor-safeHDDM™ technology, you can get high-precision measurement data for reliable use, even in challenging weather conditions. This data can be used for navigation and relative positioning tasks. Serva Transport Systems partnered with SICK to create autonomous transport robots for the factory of the future. EVE is an automated solution for production processes that uses the outdoorScan3 to go indoors and outdoors. Related White Papers Taking AGV Safety Outdoors with SICK’s New Safety Laser Scanner With a growing need for continuous improvement and automation, AGVs are being rapidly adopted in many industries. Whether used for pallet handling,…

Found in Robotics News & Content, with a score of 15.27

…Indo-MIM, a large supplier of metal injection molding (MIM) precision-engineered products with over 100 million metal parts produced annually for global original equipment manufacturers. Together, Desktop Metal and Indo-MIM will offer solutions to enable companies around the world to design and produce metal additively manufactured parts at scale and shorten time to market. Indo-MIM will draw upon its expertise in design, tooling, sintering, materials and its full range of finishing and assembly operations, to deliver precision metal 3D printed parts to companies spanning the automotive, aerospace, medical, industrial machinery industries and more. As a strategic partner, Indo-MIM will become a…