Editors’ Picks

Found in Robotics News & Content, with a score of 6.19

Supply chain automation provider Berkshire Grey Inc. today announced that it recently secured new orders of $36 million. That amount included $25 million in repeat orders from an anchor customer and $11 million from new customers such as retailer Bealls Inc. The Bedford, Mass.-based company said its total orders to date have reached $184 million and its backlog has increased to $113 million, its highest level yet. The $25 million order represents yet another follow-on order for tens of systems to be installed in different locations, according to Berkshire Grey, which said it anticipates future orders for many more locations.…

Found in Robotics News & Content, with a score of 6.17

Autonomous Mobile Robots One of the technology trends addressing these issues in the market is autonomous mobile robots (AMRs). As the name suggests, these robots move autonomously through a warehouse or fulfillment center, navigating their way with a digital map, sensors, cameras, and safety mechanisms while continuously updating the map of their environment. Should an obstacle be in their way, they simply find a way around it – without help, and digitally notating the location of the obstruction. This makes them an incredibly flexible solution for the dynamic environment of a warehouse. How can AMRs help me solve my warehouse…

Found in Robotics News & Content, with a score of 6.17

Brightpick, a provider of warehouse automation solutions for order fulfillment, recently announced that The Feed, a US-based sports nutrition and gear ecommerce retailer, has begun installation of 48 Brightpick Autopicker robots that will go live at their warehouse by the end of March 2024. The Kentucky-based company also announced a successful rollout of its Autopicker at Dr. Max distribution centers in Europe. Dr. Max is the second-biggest pharmaceutical company in Europe. Autopicker abilities in warehouses The Brightpick Autopicker is an autonomous mobile robot (AMR) that can pick and consolidate orders directly in the warehouse aisles. The robot’s patented two-tote design…

Found in Robotics News & Content, with a score of 6.17

TGW Logistics Group GmbH today announced its Quba range of mobile robots for transporting totes, cartons, and pallets. The Marchtrenk, Austria-based company said they can handle a wide range of tasks, including supplying packing or returns workstations, as well as automatic palletizing and depalletizing stations. “Mobile robots are a key technology for high-performance, flexible, and future-proof material handling operations,” stated Harald Schröpf, CEO of TGW Logistics Group. “By expanding our range in the area of driverless transport systems, TGW now offers a full package of high-performance door-to-door solutions that can also be integrated seamlessly into existing systems, both on a…

Found in Robotics News & Content, with a score of 6.16

Brown cartons whisk by at breakneck speeds as the sound of pneumatic triggers divert the cartons onto a separate path or down a chute. Red laser light beams sparkle and scan shiny white labels on the cartons checking their contents and determining their destination. Okay, we’ll admit that it’s a little difficult to romanticize warehouse automation, but it’s amazing to watch in action. All these cartons, conveyors and laser lights are part of a highly sophisticated system that continues to advance into the realm of autonomy and artificial intelligence. At the heart of this automation are two types of system…

Found in Robotics News & Content, with a score of 6.16

Just one year after its debut, the stationary piece-picking robots from RightHand Robotics (Booth B4087) for warehousing and fulfillment centers continue to evolve to address the individual unit handling needs of e-commerce and omni-channel retailers. “They’re ideal for reliably picking a wide range of variable items at high throughput rates from a tote delivered by an AS/RS or a conveyor,” said Vince Martinellli, head of marketing and products. “To make this happen, we use our RightPick AI—artificial intelligence—software.” The software overcomes the challenge that most robots face: hand-eye coordination. “They have an intelligent gripper, a vision system and software that…

Found in Robotics News & Content, with a score of 6.15

FANUC America Corp. yesterday said it will demonstrate its latest industrial automation and collaborative robots for warehousing and logistics at ProMat next week. The company will be exhibiting at Booth N7520 from March 20 to 23 in Chicago's McCormick Convention Center. “FANUC’s demonstrations will offer attendees creative ideas that incorporate automation and robotics to solve today’s challenges to increase efficiencies and help offset the labor shortage,” stated Anthony Cantrell, executive director for warehouse and logistics at FANUC America. “Key benefits to automation include improved order accuracy, higher warehouse productivity, lower operational costs, and less ergonomic issues,” he said. Rochester Hills,…

Found in Robotics News & Content, with a score of 6.15

IAM Robotics (Booth 4071) introduced itself to the world and unveiled Swift, its autonomous mobile picking robot. Named one of four finalists for the show’s “Best New Innovation” award, the company is giving live demonstrations of its breakthrough technology at the show. The robot is the key part of a complete order fulfillment solution being introduced by the company, which includes IAM Flash, a 3D item scanner and SwiftLink fleet management software. “Properly executed robotic picking is a game-changing technology for supply chain and warehouse managers,” said CEO Tom Galluzzo. “This is a dream that the material handling industry has…

Found in Robotics News & Content, with a score of 6.14

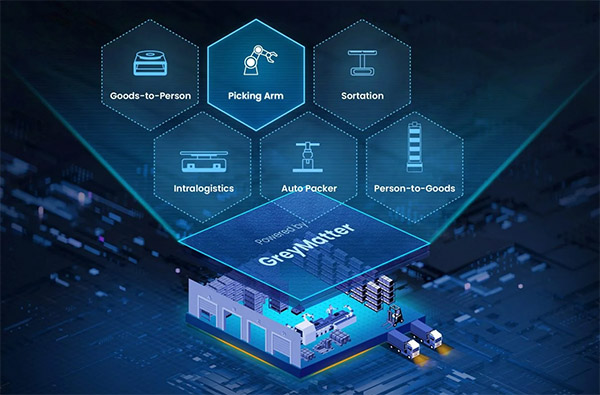

“By 2026, over 50% of companies deploying intralogistics robots in the warehouse will have a multiagent orchestration platform,” predicted a recent Gartner Inc. report. Such intelligent middleware can integrate and orchestrate work among business applications, fleets of robots, and other automated agents like doors or elevators within a warehouse or distribution center, added GreyOrange. Founded in 2012, GreyOrange said its GreyMatter hardware-agnostic orchestration platform responds to customer orders in real time, as well as proprietary and certified third-party software. The Roswell, Ga.-based company said it employees more than 800 people and has offices and partners across the Americas, Europe, and…

Found in Robotics News & Content, with a score of 6.13

Your next eyeglass order could be fulfilled faster and more accurately with robots. OSARO Inc. and Zenni Optical Inc. today announced that they have automated the “last meter” of Zenni's fulfillment center in Novato, Calif. Three OSARO Robotic Bagging Systems will prepare eyewear orders for shipment to U.S. customers. The companies claimed that the deployment is the first time in the industry that a robot will work with an automated bagging machine to ensure that a customer’s unique eyeglass order is placed into the correct bag for shipment. OSARO said its vision and grasping technology enables robots to accurately and…

Found in Robotics News & Content, with a score of 6.12

In a press conference on Tuesday, MHS (Booth N6539) detailed how key acquisitions of multiple controls, software and equipment providers—including Atronix, VanRiet and OCM—expand the company’s offerings in products, capacity and R&D innovations. “This growth enables us to offer customers complete, end-to-end capabilities as a single-source system supplier,” said Rush Fullerton, VP. “Through our extensive presence across North America and Europe, we deliver sortation, conveyor, storage and retrieval, order fulfillment, software, maintenance and other solutions worldwide.” Notably, MHS recently released its latest robotic technology: a singulation system to automate sorter induction. “It combines advanced computer vision, controls, gripping technology and…

Found in Robotics News & Content, with a score of 6.10

Innovative robotics pioneer Soft Robotics (Booth 3627) has announced the first robotic solution specifically designed for the handling of product returns. An extension of the SuperPick plat-form, the SuperPick Polybag Picking System is a new, end-to-end robotic materials handling solution designed to solve unconstrained materials handling challenges in labor starved mar-kets and can integrate across a variety of applications. “Reverse logistics and returns handling have become the center of attention for many e-commerce companies as recent studies have shown that 41% of people who purchase items online do so with the intention of returning at least part of their order,”…