Editors’ Picks

Found in Robotics News & Content, with a score of 11.69

…has continued to expand its robot portfolio for electronics manufacturing with its new IRB 1300 variant and IRB 920T SCARA options. The new IRB 1300 combines a high payload of 12 kg (26.4 lb.) and a reach of 1.4 m (4.5 ft.). It can thus handle more and heavier objects at the same time, enabling more products to be produced per hour and increasing productivity, said the company. The IRB 920T robot includes new IP54 and cleanroom options, ensuring stable production in dusty, wet, and cleanroom environments.

Found in Robotics News & Content, with a score of 11.33

…Among major robot types i.e. articulated robots, cylindrical robots, SCARA robots, and cartesian robots; articulated robots is the largest segment, accounting for $12.97 billion in 2012, owing to increasing usage of these robots currently in emerging industries such as packaging and healthcare sectors. However, cylindrical robots and other types of robots such as customized and refurbished robots are expected to grow at significant pace in the coming years due to their increasing demand in industrial sectors in Asia Pacific region. Cylindrical and other types of robots are estimated to grow at a CAGR of 6.5% and 7.5%, respectively, over the…

Found in Robotics News & Content, with a score of 10.92

…industry. The E10 controller is designed to power ABB’s SCARA robots and articulated robots with payloads of up to 11 kg (24.2 lb.) such as the IRB 920T and IRB 1300. Designed to power articulated robots with a payload of up to 300 kg (661.3 lb.) such as IRB 6700, the OmniCore V250XT controller is intended for use in electric vehicle production and general industrial applications. ABB said the OmniCore E10 and V250XT consume up to 20% less energy than its previous IRC5 controllers, thanks to power re-generation technology and brake energy recovery. This can help manufacturers improve energy efficiency…

Found in Robotics News & Content, with a score of 10.83

Delivering Complete Automation Solutions We now offer SCARA, Parallel, Articulated, and Mobile robot solutions. These best-in-class industrial robots have been integrated with Omron’s family of sensors, safety components and award-winning NX/NJ series machine automation controllers to simplify the implementation of robots in a production environment. So, what does this mean for our customers? The wide and deep range of our products open design flexibility to build electrical panels all the way up to completely automated production lines that include robotics. We engage the full scope of automation, from device to machine, to line, to factory, to enterprise to a complete…

Found in Robotics News & Content, with a score of 10.25

…a wide range of ABB robots, including articulated arm, SCARA, delta, and palletizer robots in various sizes and with various payloads. This is particularly important for machine applications where a high degree of synchronization with other components is required, for example with picking solutions. With ABB robots integrated into the machine automation system, customers will benefit from an unprecedented level of synchronization between robotics and machine control. Since the robot will no longer require a dedicated controller, all interfaces between the machine and the robot are eliminated, while the fact that all axes and sensors will now communicate on a…

Found in Robotics News & Content, with a score of 10.09

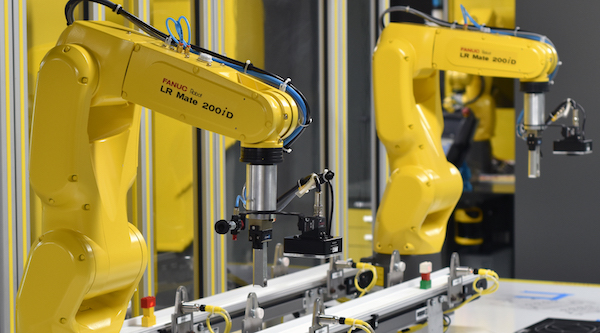

…kg (8.8 to 77.1 lb.). Cosmetics packing—A FANUC SR-3iA SCARA robot will demonstrate high-speed cosmetic packaging. The robot will use iRVision to pick products from a magazine tray and place them into a package at very high speeds. Flexible coordinated welding —This will feature FANUC’s M-900iB heavy-payload material handling robot and two FANUC ARC Mate welding robots. Visual Circular tracking —A FANUC LR Mate 200iD/4S robot uses 2D iRvision to locate random products on a circular conveyor. The cell is equipped with FANUC’s Dual Check Safety (DCS) software, designed to keep operators, robots, and tooling safe. CNC and ROBOMACHINE demos…

Found in Robotics News & Content, with a score of 9.93

…threaded rod in molded plastic. Machines such as four-axis SCARA robots can add inserts to moldings and load them into machines to continue the process. They can also present a complement of inserts to a three-axis or six-axis robot. These robots work with pick-and-place robots to complete the manufacturing process. Source: Pexels 3. Applying automation to overmolding The process of overmolding can be automated to different degrees for a more efficient and accurate arrangement of parts. Overmolding involves the removal of a molded object from one injection-molding machine and placing it into another with a robot. Six-axis robots can reduce…

Found in Robotics News & Content, with a score of 9.78

…payback. Its portfolio includes articulated arm, linear, Delta, and SCARA robots for SMEs. “We've continued added machines on RBTX and offer customers remote tests in our lab, which are easier for newcomers to automation to trust than simulations,” said Hennecke. “We also provide free 30-minute consultations and components from partners. We want to provide quotes and ship complete solutions as quickly as possible.” In addition, igus has invested in environmental sustainability through its Chainge program, which recycles the materials in used e-chains and involves Mura Technology, a partner that produces oil from plastic waste. “Our founder's dedication to sustainability drives…

Found in Robotics News & Content, with a score of 9.71

…makes the world’s smallest, most compact, and most precise SCARA and industrial robot arms. It said its customers include some of the world’s leading brands, as well as disruptors in aerospace and automotive manufacturing, as well as the medical, jewelry, and electronics industries. The Montreal, Quebec-based company welcomed the following automation providers to its network of vendors: Allied Automation, The Knotts Co,, Electromate, Pagès Group, LMZ, and Andrew Donald Design Engineering. “We’re proud to count these automation solution providers amongst our partners,” said Ahmed Mostafa, director of sales and strategy at Mecademic. “Their expertise benefits our customers, while their physical…

Found in Robotics News & Content, with a score of 9.66

…a broad portfolio of articulated arm, linear, delta, and SCARA robots. Product modularity means that single components, or complete individual solutions, can be assembled according to the build-or-buy principle. The focus is always on a low entry-level price and quick payback. This is where igus high-performance plastics play to their strengths. They are tribologically optimized and especially durable. Engineered plastics from igus are lightweight, dry-running, maintenance-free, and cost-effective to produce. The most cost-effective solution that works Over the past three years, igus has built up a broad, constantly growing partner network. As part of the LCA partner program, the motion…

Found in Robotics News & Content, with a score of 8.83

…to a Quest QP200-SA2 case packer, where FANUC articulated SCARA and articulated robots orientate, pick, and place shrink-wrapped canisters by CL&D into the awaiting trays. Next, a Tekkra T-1030 in-line shrink-bundler system from Texwrap will wrap the trays containing 12 canisters each with film. The Tekkra T-1030 is a continuous-motion shrink bundler with a servo-driven seal bar and carriage. It is best for medium to high-speed applications, noted ProMach. Finally, a Quest Box Bot QB320 space-saving robotic palletizer will pick up wrapped trays and place them on a floor-level pallet to complete the demonstration, explained the company. Every Box Bot…

Found in Robotics News & Content, with a score of 8.62

…and Markets. The analyst firm noted that it includes a variety of robot types, from collaborative and parallel to SCARA. Clean room robots have a few key risks, but they are still generally safer than humans in highly sensitive manufacturing environments. Engineers must ensure that such robots are able to operate effectively in clean rooms by taking steps to prevent accidents and contamination. Innovative robotic grippers, interior vacuums, and non-conductive materials can help clean room robots work safely and efficiently. About the author Emily Newton is a tech writer who enjoys writing about the latest innovations changing our world. Read…