Editors’ Picks

Found in Robotics News & Content, with a score of 5.83

…the shape and other features Develop an adaptable end-of-arm-tooling (EOAT) to adjust to the geometry of the fabric piece to be picked up Leverage the fabric gripper technology developed by Apparel Robotics Beyond garment manufacturing, the proposed system could bolster automation capabilities in aerospace and other industries working with flexible, fabric-like materials. Collaborative Framework for Robotics Training Project team: Aris Technology (principal investigator) Topic areas addressed: Multi-robot, multi-human collaboration, task sharing, and task allocation Description: Robotic adoption has been limited by a lack of flexible robotic systems and difficulties in upskilling a large industrial workforce. Enabling shop-floor operators with the…

Found in Robotics News & Content, with a score of 5.72

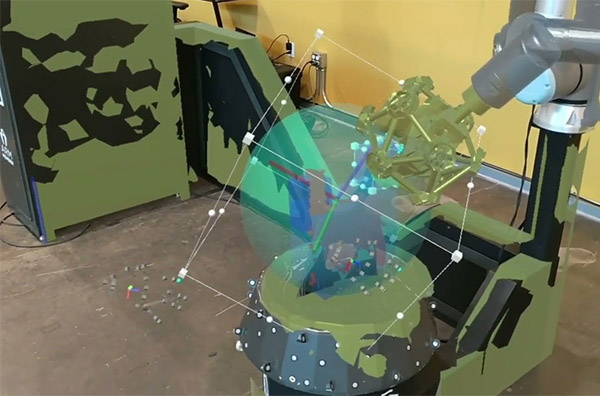

…capabilities. Advances in machine vision, software, and end-of-arm tooling (EOAT) have led to a wider range of applications. Picking of jumbled or mixed pieces is getting faster and more accurate, with less AI overhead. CapSen Robotics, Mujin, and Soft Robotics provided some examples. Most of the collaborative robot suppliers showed welding cells, with Universal Robots leading the way with its first cobot TIG welding and spot welding applications with partners THG Automation and Pro Spot, respectively (see video below). Kane Robotics and FerRobotics used a UR cobot to demonstrate grinding and surface finishing (see photo, top right). Affordability and ease…

Found in Robotics News & Content, with a score of 5.42

…to 200-400 millimeters per second depending on end-of-arm tooling (EOAT) and size of product being handled. Further zones are commonly set at 400-1000 millimeters per second. On the end of its cobot arms, Yaskawa installed an indicator light that turns green when the robot is operating in collaborative mode - meaning humans can safely approach it - and turns off when the robot operates in industrial mode. Minimizing footprint while maximizing workflow One challenge manufacturing and logistics warehouses must consider is how to accommodate the footprint of robotic workcells. The goal is to limit how much floor space each robot…