Editors’ Picks

Found in Robotics News & Content, with a score of 1.37

…low-code, cloud-native platform for its versatility, development speed, and ease of use,” he added. “The Boomi platform will enable us to connect our operations with our shippers, suppliers, and partners, while mitigating potential real-time supply chain issues.” Geek+ needs to simplify data for growth Geekplus Co. was established in Japan in 2017 as a joint venture between Beijing-based autonomous mobile robot (AMR) provider Geekplus Technology Co. and Japanese capital. The company provides services such as sales, installation, 24/7 maintenance, and productivity improvement consulting. With customers in retail, apparel, pharmaceuticals, automotive, lithium batteries, photovoltaics, electronics, and more in thousands of locations…

Found in Robotics News & Content, with a score of 3.77

…robots met and exceeded those expectations. Proof of the ease of use of our solutions, the pilot robot was operational the very afternoon following its delivery to the site,” said Pascal Rialland, CEO of BALYO, in a statement. “The deployment of a fleet of 10 robots within this site is planned over H2 2023,” he said. “This new deployment is an example of the many advances made by BALYO in recent years, both in terms of performance and ease of use of our robots.” “The robotization of logistics flows remains at the heart of the challenges facing manufacturers and BALYO…

Found in Robotics News & Content, with a score of 0.63

…real-time monitoring and troubleshooting. Source: Exotec Balancing innovation and ease of use “Instead of starting with hardware and then doing a little software development, they go hand in hand for us,” Bellamy said. “Including something as traditional as a conveyor, we bring a modern, robotics view to it.” “For manipulation and grasping, we looked at what the market was doing, and we developed our systems and software to do that,” he added. “Exotec's Deepsky software comes with regular updates, so there's one version across our installed base around the world. Wherever Skypod is running, performance optimization is included, so customers…

Found in Robotics News & Content, with a score of 1.21

…safety improvements. That includes minimal training for warehouse associates, ease of use through intuitive user interfaces, and a reduction of the distances that employees must walk by about 50%. Körber said its system also contributes to a safer and more ergonomic environment for all warehouse associates. In addition, the integrated AMRs can minimize exhaustion, stress, and the risk of injury-prone activities such as loading and pushing carts, the company said. “Being a long-standing Körber partner and understanding our capability in delivering complete end-to-end software, robotics, and operational solutions, Lambert looked to us when it was time to take the next…

Found in Robotics News & Content, with a score of 1.37

…million ($6.6 million U.S.) in 2021. Locator designed for ease of use Bosch Rexroth claimed that Locator can simplify the automation of intralogistics tasks in different industries without specialized knowledge or additional infrastructure. The software evaluates the signals from a laser sensor in the robot or vehicle and converts them into coordinates in space. Users do not need permanently installed aids, such as markers or reflectors, for position determination, said the company. They need only one click to start up the system and familiarize the unit with its surroundings in a one-time orientation trip, explained Bosch Rexroth. The company provides…

Found in Robotics News & Content, with a score of 1.35

…by BALYO in recent years, in terms of performance, ease of use, flexibility, and the fast deployment speed of our robots and technologies,” said Rialland. “The robotization of logistics flows for high-bay storage remains an untapped challenge facing manufacturers and logisticians, and BALYO is perfectly positioned to meet this growing demand,” he added. BALYO partners for global reach To accelerate the material handling market conversion to autonomy, BALYO has entered into two global partnerships with KION (parent company of Fenwick-Linde) and Hyster-Yale Group. The Arcueil, France-based company has subisidiaries in Woburn, Mass., and Singapore and serves clients in the Americas,…

Found in Robotics News & Content, with a score of 1.80

Front AGV and Kollmorgen Automation have teamed up to develop automated guided vehicles, or AGVs. Front AGV is a part of 3Button GROUP AB and said it makes AGVs and AMRs “to cover a range of processes in the manufacturing line; from machine tending, assembly and labeling to picking, packing, and palletizing.” It is an authorized partner of ABB and sells mobile robots developed by ASTI, which was acquired by ABB in 2021. 3BUTTON GROUP AB is made up of Front AGV AB, Front Automation AB, Fröjd Automation AB, and IML Technologies AB. Kollmorgen Automation said it caters to automakers…

Found in Robotics News & Content, with a score of 1.26

…“We pride ourselves on producing automated machines that prioritize ease of use for the teams using them and in deploying these machines quickly and efficiently all across the world.” said Bruno Ferraty, strategic account manager for Europe, the Middle East, and Africa (EMEA) at Tennant. “With this partnership, we have seen the best of these, with a rapid and well-coordinated rollout and Albert’s in-store teams welcoming the introduction of robotic co-workers able to take over the mundane and repetitive cleaning tasks,” he said. Since the start of the national deployment in Albert stores, Brain Corp said BrainOS-powered robotic scrubbers have…

Found in Robotics News & Content, with a score of 2.16

…automation trade shows because of its versatility, cost-effectiveness, and ease of use, said the company. Source: OnRobot Overcoming tradition Traditional robotic palletizers are highly effective, but they are also expensive—not just in terms of the initial capital outlay, but also due to the costs associated with set up, programming, and ongoing maintenance. For cash-strapped small and midsize enterprises (SMEs) struggling to find a solution to long-term labor shortages, the numbers don’t add up. Footprint is also a challenge. Traditional palletizing robots take up a considerable amount of precious floorspace compared with the alternatives because of the size of the robots…

Found in Robotics News & Content, with a score of 1.88

…advantage of an adaptive robot’s efficiency, flexibility, customizability, and ease of use, according to Flexiv. Created to address the shortcomings of collaborative robots, adaptive robots offer their users artificial intelligence, industry-leading force control, and computer vision integration to achieve unmatched precision, it said. Flexiv heads north “We are very excited to partner with an established and experienced system integrator in the Canadian market,” said Daire Kullar, Flexiv’s regional sales and business development manager. “Sycodal has opened a door for Flexiv in this market, and we are committed to supporting their growth. We are confident of the abilities Sycodal has to…

Found in Robotics News & Content, with a score of 1.02

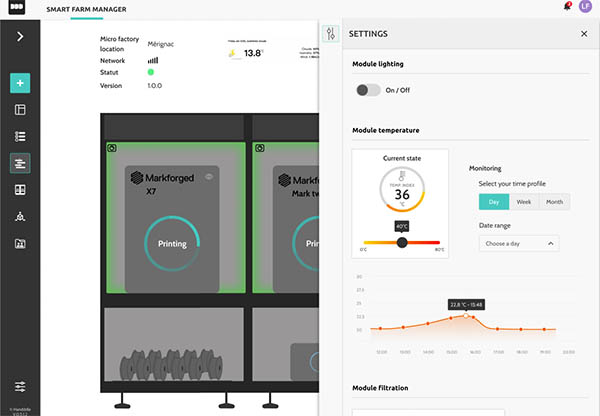

…that we were able to test at Gryp3D with ease of use and concrete results [not only] in production, but also in business,” explained Gauthier Laviron, CEO of Gryp3D, which reproduces vintage car parts. “Beyond saving time in managing daily external disruptions and improving our traceability, we have been able to show our strategic customers how we could control our production processes with an integrated solution.” Handddle noted that the integration lets Markforged customers increase distributed manufacturing capabilities by duplicating identical production environments anywhere in the world. Markforged and Handddle are each exhibiting at Formnext from Nov. 15 to 18…

Found in Robotics News & Content, with a score of 0.77

…cited bridge manufacturing as an example of the software's ease of use with existing cells or turnkey setups. It works with existing programmable logic controllers (PLCs) and standardized APIs. “While all bridges are different, an operator can upload a 3D model, select the joints to be welded, and press a button,” said Golitsyn. “There's no orientation planning, and our software can automatically identify weld joints. The user can define parameters and change the sequence.” “Once the task has been defined, the robot can execute it,” he said. “I can create a task in California and execute it in Chicago. Like…