Editors’ Picks

Found in Robotics News & Content, with a score of 0.79

…said. Guha's department is also collaborating with other departments at Penn State University to contribute to the fight against COVID-19. “My colleague Dr. Tim Simpson helped organized Penn State's response initiative, which leverages Penn State University's research enterprise to uncover potential solutions,” Guha explained. Dr. Timothy Simpson was a panelist for a previously produced DE webcast on AM design's pitfalls. For more on what Dr Guha and his colleagues are doing in collaboration, visit MASC@PSU

Found in Robotics News & Content, with a score of 8.13

…automation sector was not in a great place before COVID-19 struck, having been slowed by flat capital expenditure and declining industrial production, says GlobalData, a leading data and analytics company. The virus has since closed factory after factory worldwide with workers sent home. The reality, according to GlobalData, is that despite much hype over the years, advanced factory automation has not been substituted for human workers at scale. “By the time it expires, COVID-19 may have served to at last accelerate an investment in factory automation when the global economy eventually rebounds,” said David Bicknell, principal analyst, Thematic Research at…

Found in Robotics News & Content, with a score of 3.69

…high-impact projects that support the nation’s response to the COVID-19 pandemic. Using funds appropriated by the Coronavirus Aid, Relief, and Economic Security (CARES) Act, NIST will award the grants through the NIST Manufacturing USA National Emergency Assistance Program with no requirements for cost matching. Funding will be awarded to eligible Manufacturing USA institutes, a network MxD has been part of since its inception. MxD is focused on helping the defense industrial base bolster national security and public health in response to COVID-19—and working to be better prepared for future crises. MxD is actively working on a response to this opportunity,…

Found in Robotics News & Content, with a score of 2.75

The current COVID-19 crisis has brought to light a critical problem in the medical supply chain in the U.S. With many supplies such as personal protective equipment (PPE) coming from overseas, healthcare providers face shortages of masks, gloves, face shields, and other supplies. In addition, the current supply of ventilators was woefully low even before the pandemic. With its rapid and distributed production capabilities, additive manufacturing technology was literally built for such a moment. Printer manufacturers, technology companies, and engineers are stepping up to help fill the gap in the medical supply chain—and more help is needed. Universities (and some…

Found in Robotics News & Content, with a score of 1.39

Students at Camdenton High School are using 3D printers to help produce hundreds of face shields for healthcare workers at Lake Regional Hospital in Osage Beach, MO. The printers were provided by nearby Camdenton Middle School, which received them as part of a $16 million grant from the MU College of Education’s eMINTS National Center. “To see the face shields being used by medical professionals is encouraging and the reaction has been super positive,” says Zane Foulk, a senior at Camdenton High School and member of the Camdenton For Inspiration and Recognition of Science and Technology (FIRST) Robotics team. “We…

Found in Robotics News & Content, with a score of 1.58

Hospitals are in need of mechanical ventilators to treat COVID-19 patients. In response to this shortage, Materialise has developed the Materialise NIP Connector, a device to convert standard equipment available in most hospitals, into a mask to facilitate breathing for patients by creating positive pressure in the lungs. These assembled masks allow clinicians to reduce the time patients need access to mechanical ventilators, which helps to reduce the strain on ventilator supplies. Materialise is now fast-tracking the regulatory registrations that are crucial to ensure the safety of patients and caregivers. The company expects to have the device broadly available for…

Found in Robotics News & Content, with a score of 1.59

…millions of face shields available in the fight against COVID-19. Fictiv has invested in the upfront tooling costs to make the shields available as quickly and easily as possible to healthcare agencies, service providers, distributors and even non-healthcare OEMs that are pivoting to support the healthcare industry during this crisis. The pricing will be matched to cost, and additionally, any longer-term profits beyond initial tooling and unit manufacturing costs will be donated to the COVID-19 Solidarity Response Fund for WHO. The shield is based on open-source face shield designs, similar to the visor recommended by the National Institutes of Health…

Found in Robotics News & Content, with a score of 9.15

…(NIH), America Makes launched the next phase of the COVID-19 Health Care Needs and Additive Manufacturing (AM) Capabilities Repository, where additive manufacturers can upload 3D print designs to be reviewed and placed on the NIH 3D Print Exchange. Designs submitted through the America Makes design submission form in connection with NIH 3D Print Exchange, will be placed in a fast track workflow for faster review. Designs not submitted through the America Makes process may not be considered for the fast track workflow. All designs will be publicly accessible through the NIH 3D Print Exchange website with their designation. “We have…

Found in Robotics News & Content, with a score of 3.79

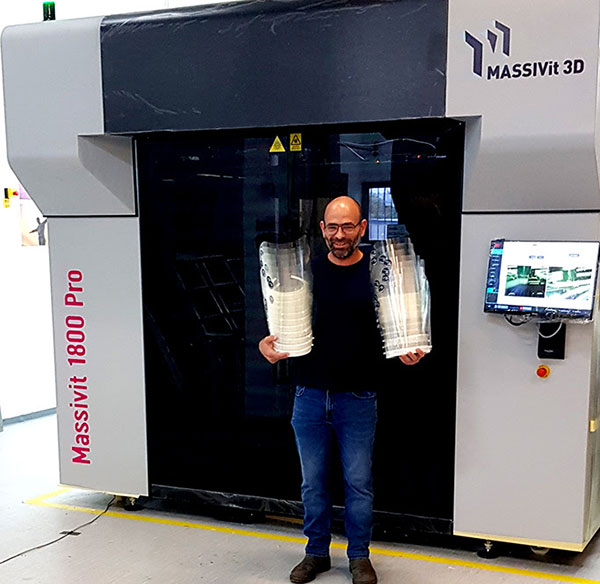

…announced its global contribution to the combat against the COVID-19 pandemic. By dedicating its resources and mobilizing its network of over 100 customers and distributors worldwide, ergonomic PPE Face Shields have been conceived and produced to address the demand by medical teams caring for the victims of the pandemic. Massivit 3D’s high-speed additive manufacturing technology allows for the supply of hundreds of face shields off each machine every day. In addition to devoting all of its manufacturing resources to producing and donating thousands of face shields to medical teams at local hospitals with a less than one-day turnaround, the company…

Found in Robotics News & Content, with a score of 1.80

Dealing With The Impacts of COVID-19 When the Centers for Disease Control (CDC) responded to an outbreak of respiratory disease caused by a novel coronavirus in late-2019, the outbreak’s far-reaching consequences couldn’t have been predicted. Now here we are, dealing with the impacts of COVID-19 around the world. Whether they’ve sent their workforces home to work remotely, scaled back their operations, or scrambled to find alternative supply sources, organizations across all industries are implementing new measures to offset the impacts of COVID-19. A moving target right now, just the extent of the short- and long-term effects on organizations and individuals…

Found in Robotics News & Content, with a score of 0.80

…for patients who have or are suspected to have COVID-19. Baptist Health has 11 hospitals and more than 150 urgent care centers and physician offices in the four-county area from Monroe to Palm Beach counties. FIU's College of Communication, Architecture, + The Arts (CARTA) is at the center of the initiative, mobilizing its 3D printing facilities, faculty, staff and students to produce a minimum of 1,000 face shields for Baptist Health. More than 30 3D printers housed in the college's CARTA Innovation Lab in the Miami Beach Urban Studios (MBUS) are printing the protective equipment, as well as additional printers…

Found in Robotics News & Content, with a score of 0.61

…printing of metal parts will increase in response to COVID-19 and the effect of the pandemic on U.S. manufacturing, especially with manufacturers that rely on complex supply chains. 3D printing is more agile and rapid in development and execution than traditional manufacturing methods and can be performed proximate to where the end product is needed, making it much more responsive in times of crisis, the company says. PrintRite3D Production Series enhances this speed and agility by truncating the design and development process and accelerating the 3D manufacturing machine qualification and has the added advantage to remotely monitor production in real-time…