Editors’ Picks

Found in Robotics News & Content, with a score of 7.77

…provider of delta robots, which are used primarily for high-precision pick and place applications. Codian Robotics’ offering includes a hygienic design line, ideal for hygiene-sensitive industries including food and beverage and pharmaceuticals. With the transaction, ABB is accelerating its engagement in the growing field of delta robots. Codian Robotics is located in Ede, Netherlands and employs 20 people globally. The company will continue to serve its customers directly. The acquisition was signed and closed on October 1, 2020 and both parties agreed not to disclose any details regarding the purchase price. “Our acquisition underscores our focus on breakthrough technology, helping…

Found in Robotics News & Content, with a score of 8.62

…maneuvering packages in warehouses requires a high degree of precision, these SensorApps were developed to allow for the smooth automated flexibility of mobile robots. Human workers also receive significant help from these solutions, thus allowing for a safer and more efficient process. Dolly Positioning SensorApp When it comes to automation, success lies in precision. The automated pick-up of dollies with an AGV requires exact identification of the place and position of the dolly. The Dolly Positioning SensorApp helps satisfy this requirement within a working range of 1.5-3m. It works by positioning the camera in front of the dolly chassis The…

Found in Robotics News & Content, with a score of 6.82

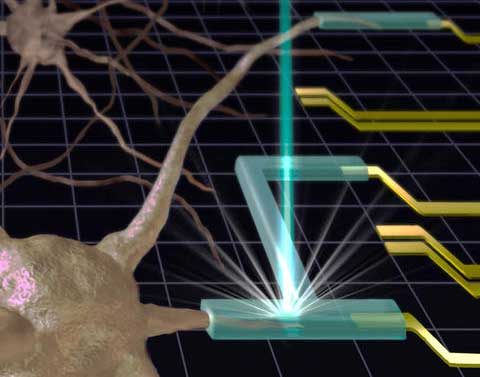

…new paper, it may create complex structures with nanometer-scale precision. Because many gels are compatible with living cells, the new method may boost the production of soft tiny medical devices such as drug delivery systems or flexible electrodes that can be inserted into the human body. Using a 3D printer to fabricate an object made of gel is a “bit more of a delicate cooking process,” as NIST researcher Andrei Kolmakov describes it. In the standard method, the 3D printer chamber is filled with a soup of long-chain polymers—long groups of molecules bonded together—dissolved in water. Then “spices” are added—special…

Found in Robotics News & Content, with a score of 12.47

…3DP and manufacturing and will reveal how some new developments at BMF are making micro production parts possible using micro-precision 3D printing. Tune in to learn: What applications can micro-scale AM/3DP be used for How to pick the right material and resolution for your application How micro 3DP materials stack up to micro manufacturing materials Click here to register. Sponsored by: Speakers: John Kawola CEO Boston Micro Fabrication Moderator: Kenneth Wong Senior Editor Digital Engineering

Found in Robotics News & Content, with a score of 3.30

…answer, but for one of Northern Europe’s leading retailers, it is “a world-class facility that we use as a precision tool for inventory management to deliver the correct items to our stores, when they need them,” Eriksson says. “And, we have the warehouse capacity we need for the foreseeable future. We no longer talk about the limitations of our supply chain, just about how well everything runs.”

Found in Robotics News & Content, with a score of 4.74

…meter with metering extruder technology (MXT), which offers speed, precision and control over materials deposition when dealing with large-scale parts. The BigRep PRO’s print bed is outfitted with sensors and hardware to allow for semiautomatic print bed leveling—another way the printer ensures repeatable, high-quality parts. One more differentiator is the integration of a state-of-the-art Bosch computer-numerically controlled motion-control system, designed to deliver maximum responsiveness and accuracy along with closed-loop controls. Untethered from the volume constraints of a traditional build plate, large-scale AM gives engineers the freedom to orient parts in a way that makes the most sense, whether it’s to…

Found in Robotics News & Content, with a score of 8.93

…footprint in additive manufacturing,” says Marc Riquelme, president of Signicast. The partnership between Signicast and DDM highlights advancements in precision casting technologies and opens up new design opportunities. Signicast expects to transition this technology for full-scale production runs in addition to prototyping. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 6.30

…technology and process that enables the manufacture of complex, high-precision mechanical parts at much faster speeds and much less cost versus traditional solutions, according to Fictiv. The data produced from Fictiv’s digital thread helps drive automation through the Fictiv DME to speed up production and prevent errors. For example, every part produced through the Fictiv DME receives a minimum of five dimensional inspections, with the resulting data captured digitally for fast and simple validation by Fictiv teams and customers. “Historically, companies were working in the dark, relying on paper-based workflows, including phone calls late at night, file transfers, emails, and…

Found in Robotics News & Content, with a score of 7.65

…a new level of performance to the warehouse floor. By collaborating with Geek+, Kӧrber provides the flexibility, adaptability and precision businesses need to conquer supply chain complexity today and beyond.” “With the right technologies and partner, businesses can turn today’s supply chain complexities into a strategic differentiator with robotics,” said John Santagate, vice president of robotics at Kӧrber Supply Chain – Software. “Be it the rise in consumer expectations, increasing product counts, supply network complexity, or growing distribution channels, Kӧrber’s relationship with Geek+ empowers businesses to effectively integrate mobile robotics into their operation in the effort to revolutionize workflows across…

Found in Robotics News & Content, with a score of 14.39

…worldwide. The software is popularly used in companies requiring precision machining, such as shops in the automotive and aerospace industries. TITANS of CNC Aerospace Academy is a project-based platform teaching high-level manufacturers the skills necessary to produce complex aerospace parts using the most difficult materials. TITANS of CNC, Inc. CEO Titan Gilroy and his team have worked to create the Aerospace Academy as a platform to highlight aerospace machining and processes, that gives users an inside look at the entire process of manufacturing complex, hard-to-machine parts, that are realistic to the industry. Mastercam is featured throughout the platform and content…

Found in Robotics News & Content, with a score of 7.82

…just 3D printed it on the [Zortrax] Inkspire”, said Błaszczak. The Inkspire printer is described as capable of surgical precision—50x50 microns with minimal layer height of only 25 microns. “The black resin, when applied in relatively thin parts, exhibits limited light-transmitting properties. Basically, the part designed and 3D printed to mimic the geometry of the original Ferrari cover looked the same when the diodes on the wheel were lighting up,” wrote Zortrax in a blog post about the project. Zortrax Inspire printer prints in resin.

Found in Robotics News & Content, with a score of 8.79

…capabilities of Jabil through a single digital thread. Beyond the 3D printing of parts, Jabil can now leverage Fictiv’s precision service model to offer volume manufacturing, data, packaging and on-time fulfillment to end customers with less risk. Sources: Press materials received from the company and additional information gleaned from the company’s website.