Editors’ Picks

Found in Robotics News & Content, with a score of 19.75

…of 2021 and the 8 m (26.2 ft.) tall micro-fulfillment RoboShuttle. “Our approach has been to study our goods-to-person installations worldwide and conduct in-depth discussions with customers to further innovate in the space and develop the products that can fit their more complex needs,” Liu added. “Goods-to-person is just the tip of the iceberg for what AMRs can provide to warehouse logistics.” More storage space than traditional systems Compared with manual warehouses that use beam racks for storage and shipment, the four-way shuttle racks provide higher and denser storage spaces without compromising worker safety, according to Geek+. On the ground…

Found in Robotics News & Content, with a score of 6.86

Locus Robotics Corp. today announced that it has added the Locus Vector and Locus Max to its line of autonomous mobile robots, or AMRs. These new models join the Locus Origin robot to address a broad range of warehouse use cases, said the Wilmington, Mass.-based company. The new AMRs address e-commerce, case-picking, and pallet-picking applications, as well as supply chain scenarios requiring larger, heavier payloads, said Locus. The company acquired Nashua, N.H.-based Waypoint Robotics Inc. in September 2021. “With these new LocusBots, we’re able to help our clients alleviate significant labor challenges and achieve optimal productivity by using the right…

Found in Robotics News & Content, with a score of 7.77

In advance of the MODEX 2022 supply chain trade show, two companies addressed the challenge of automated bagging. Berkshire Grey Inc. and OSARO Inc. last week both announced new products that they plan to show in Atlanta. “Warehouse and logistics operations globally are wrestling with an acceleration of consumer demand and a shortage of labor,” stated Derik Pridmore, CEO of OSARO. “By automating common manual processes such as movement, storage and retrieval, and picking and placing, fulfillment centers and e-commerce operations can become more efficient and cost effective—and improve employee safety.” “Berkshire Grey’s Robotic Pick and Pack with Identification system…

Found in Robotics News & Content, with a score of 5.49

Kindred Inc. this week announced it will bring to market an AI-powered robotic system designed to automate the small parcel induction process. Built on Kindred’s proprietary CORE/AutoGrasp artificial intelligence platform, the INDUCT robotic system is a high-speed workcell that identifies items and determines how to handle them, a process known as induction. The San Francisco-based company said the system accurately picks, maneuvers, and places items onto a moving belt, bomb bay, or tilt sorter. The platform combines AI-powered machine vision, grasping, and manipulation algorithms to handle parcels of varying size, fragility, and materials. INDUCT system to help address shortages The…

Found in Robotics News & Content, with a score of 3.11

Labor shortages and the COVID-19 pandemic have posed serious challenges for warehouses and distribution centers. Honeywell International Inc. yesterday announced a strategic collaboration with OTTO Motors to provide automation throughout North America for help with labor-intensive tasks, such as moving carts, pallets, or totes. Honeywell said the partnership enables its customers to increase efficiency, reduce errors, and improve safety by deploying OTTO Motors’ autonomous mobile robots (AMRs) in their facilities. “Supply chains continue to be stressed by staffing shortages and consumer demands driving expectations of speedy and accurate fulfillment,” said Keith Fisher, president of Honeywell Intelligrated. “Tackling the more dynamic,…

Found in Robotics News & Content, with a score of 3.31

HAI Robotics, an autonomous case-handling robot maker, will present its flexible totes-to-person warehouse automation products at MODEX 2022. The company's exhibits this year include two types of autonomous case-handling robots and one workstation that was crafted to explore the full potentials of order-fulfillment efficiency, deployment flexibility and scalability in a goods-to-person order-handling context, the company said. HAIPICK enables higher storage density The HAIPICK A42T robot to be displayed is an evolution of the company’s IFOY 2021 “Best in Intralogistics” title earner. With a telescopic lift function that can flexibly adjust its picking height, it can handle bins (totes or cartons)…

Found in Robotics News & Content, with a score of 5.45

Cimcorp and Muratec plan to showcase their range of automation technologies at the MODEX 2022 supply chain trade show next week. Both companies are owned by Japan-based Murata Machinery Ltd. Technologies featured will include robotic order-picking systems, as well as automated storage and retrieval systems (ASRS). They will also have live automated guided vehicle (AGV) demonstrations. As integrators of intralogistics systems for industries including food and beverage, grocery, retail, medical, and automotive, both Muratec and Cimcorp said they help customers improve warehouse and distribution efficiency, sustainability, and profitability by customizing systems designed to fit their needs and specifications. Booth visitors…

Found in Robotics News & Content, with a score of 3.73

During MODEX 2022, RIOS Intelligent Machines Inc. is presenting a seminar, “Getting Started with Robots as a Service: Robotic Workcells to immediately Increase Productivity and Supplement Labor.” Mandy Dwight, vice president of business development, and Dr. Clinton Smith, co-founder and chief technology officer, will present RIOS's session on robotics-as-a-service (RaaS). Facilities and operations can gain insights on how to maximize profit streams with the RaaS model with no upfront costs or large, unforeseen maintenance fees. RIOS also said that attendees can learn how robotic workcells as a service is transforming businesses every day and increasing productivity, despite limited labor resources.…

Found in Robotics News & Content, with a score of 3.72

Next week at the MODEX 2022 supply chain trade show, Universal Robots ApS will have several live demonstrations highlighting how its customers are using its collaborative robots. Odense, Denmark-based Universal Robots (UR) is the market leader in the cobot space, with a 44% to 47% market share. Cobots go to work depalletizing At Universal Robots' booth B2805, visitors will learn how automation company Mujin is using Universal Robots' UR10e for mixed case depalletizing. “Collaborative robots have completely changed the way industry utilizes robotics,” says Josh Cloer, director of sales at Mujin. “UR brings flexibility, ease-of-use and ready-to-deploy tools making it…

Found in Robotics News & Content, with a score of 3.34

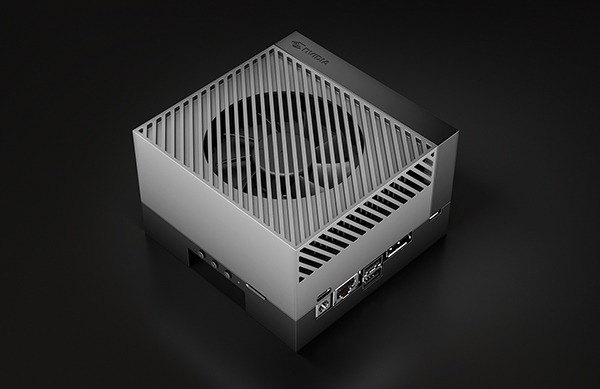

As e-commerce accelerates demand for warehouse automation, robots need to become more perceptive and smarter. At its Spring 2022 GPU Technology Conference, or GTC, NVIDIA Corp. today announced the availability of its Jetson AGX Orin developer kit and its Isaac Nova Orin architecture for autonomous mobile robots. “Modern fulfillment centers are evolving into technical marvels — facilities operated by humans and robots working together,” said Jensen Huang, founder and CEO of NVIDIA. He said new processors, software, and simulation capabilities will lead to “the next wave of AI,” including robots able to “sense, plan, and act.” NVIDIA claimed its invention…

Found in Robotics News & Content, with a score of 10.95

As supply chains struggle with shifting consumer behavior and widespread labor shortages, robotics providers must demonstrate the value of their offerings. Berkshire Grey Inc. and Swisslog Holding AG today announced that they are partnering to help customers with automation, with an initial focus on the Americas. “Swisslog is excited to partner with Berkshire Grey,” stated Markus Schmidt, president of Swisslog Americas. “We view this as a first step in a fruitful relationship with Berkshire Grey. “Together, we will continue to shape the future of data-driven, robotic solutions by providing the next generation of warehouse automation and creating reliable and unparalleled…

Found in Robotics News & Content, with a score of 1.49

“Integration” is considered a dirty word by many in industry. Sure, there are more software and automation tools than ever, but getting them to play nicely with one another can still be a major challenge. CJ Logistics wanted to add robots and other technologies to a 1.1 million-sq.-ft. facility in Dallas, but it needed to address integration with the help of SVT Robotics. “This was a strategic initiative for our company,” said Laura Adams, vice president of technology, engineering systems, and solutions (TES) at CJ Logistics. “In this particular building, we wanted to deploy several technologies that CJ Logistics is…