Editors’ Picks

Found in Robotics News & Content, with a score of 5.71

…heavy material handling equipment to increase safety, productivity, and precision in the rebar assembly process. Construction in digital transformation The construction industry has been undergoing a transformation as it adopts digital technology and addresses resiliency and sustainability within existing trades and practices, said Toggle. Reinforced concrete is the fundamental building block of cities and infrastructure, so the steel reinforcement that provides its structural integrity is a natural place to start this evolution, according to the company. Toggle said its patent-pending full-stack systems for rebar fabrication and assembly. The company said its technology is a new approach to a wide range…

Found in Robotics News & Content, with a score of 5.71

…human performing the same task. Robots can also improve precision, accuracy, and cycle times, lessening waste and minimizing errors. Simply put, robots can make a big difference in cost-effectiveness and production waste while freeing workers from repetitive manual work. Robotics has tremendous potential to change the future of business operations. The robotics market could reach $214.68 billion (U.S.) by 2030 with a compound annual growth rate (CAGR) of 22.8%, estimated Market Research Future. As robotics becomes essential to every industry, manufacturers should consider taking advantage of automation for plastic injection-molding operations to keep up with rapidly changing market needs. About…

Found in Robotics News & Content, with a score of 5.68

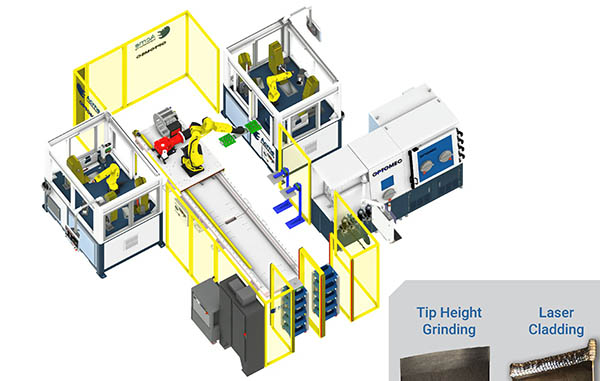

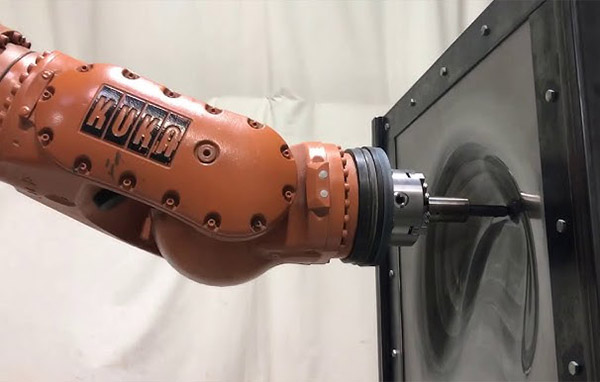

…CS-250 five-axis laser cladding machine can produce high-quality, high-yield precision welds for titanium compressor blades using proprietary LENS DED and AutoCLAD advanced vision and adaptive tool-pathing technology in a controlled argon atmosphere. The Acme Manufacturing MRO blade-tip repair machines can be configured for blade tip grinding, weld blending, and polishing. The partners said the system is equipped with “first of its kind” auto path generation, which allows for a high-mix, low-volume production environment. This new technology is three to four times faster than traditional CNC machines, they claimed. Optomec, Acme Manufacturing serve MRO centers Working in tandem, the systems in…

Found in Robotics News & Content, with a score of 5.64

…yard technologies, including deep-learning based robotic brake line connections, high-precision articulated backing, and autonomous hitching for diverse trailer weights and orientations. In January, Outrider raised $73 million in a Series C round, bringing its total funding to $191 million. Outrider works with customers in industries, such as consumer packaged goods, retail and eCommerce, package shipping, manufacturing, and intermodal rail. Outrider was recognized in Fast Company’s prestigious 2022 World’s Most Innovative Companies list, placing in the top 10 in the logistics category. With its customers representing over 20 percent of all yard trucks operating in North America, Outrider is a private…

Found in Robotics News & Content, with a score of 5.64

…cobots to perform certain repetitive tasks and supervise them, effectively multiplying their efforts. Plus, robots can move with computerized precision, ensuring that every single measurement is perfectly accurate. Most robot models have a system for saving previous work, so users can pull from a growing library of programs to easily perform a weld without any robotics expertise needed. About the author Caption Emily Newton is a tech writer who enjoys writing about the latest innovations changing our world. Read more of her articles online at Revolutionized Magazine.

Found in Robotics News & Content, with a score of 5.62

…With the use of robots, companies can get that precision in less time. “It is extremely difficult and takes a long time to get proficient at welding, at least to the point where you can make a career out of it,” Eckdahl said. “I’m not a welder by any means, but I can make the robot put down some very pretty wells.” During the open house, Vectis’ cobot was emulating the motions of welding from a variety of angles. The Loveland, Colo.-based company also has a plasma-cutting deployment option. It sells its products as integrated systems and includes EOAT and…

Found in Robotics News & Content, with a score of 5.60

…it beyond anyone’s expectations. “They rapidly transitioned from producing precision parts to producing medical face shields. When the shortage of quality shields was noted, within days they were producing PPE to be used by our region’s front line EMS and Healthcare workers.” Highlands Appalachian Regional Healthcare Medical Center in Prestonburg was one of the first recipients. Tim Hatfield, Community Chief Executive Officer: “ARH is proud to have a community partner like eKAMI to support our system. Over the past several weeks, eKAMI has worked to produce 1,750 face shields for our front-line staff. We are truly blessed with Kathy Walker,…

Found in Robotics News & Content, with a score of 5.59

…of the workpieces do not affect the functionality and precision of the system, it asserted. “By automating processes with MIRAI, we can save costs and position ourselves as an innovative and modern company while enhancing the attractiveness of our workplace,” Lembke said. Since implementing MIRAI, HWL reported that its employees have taken on the responsibility of managing and retraining the system, which is especially important when faced with changing requirements or environmental modifications. “The fact that these adjustments can be made by our employees without the need for experienced programmers from the manufacturer is a significant advantage,” said Lembke. “We…

Found in Robotics News & Content, with a score of 5.58

…arms which features several models with capabilities ranging from precision arms for surgical applications, rugged outdoor arms for construction tasks, and the Sapien Sea Class system that can operate in shallow and deep water to perform inspection and maintenance tasks across multiple industries. Sapien products are expected to provide earlier revenue and commercial release for the combined company. Sarcos said RE2 has significant program wins in surgical robotics, aviation maintenance, and construction automation. It has also sold more than 650 robotic arm products capable of operating in unstructured environments into the market since 2010. The company said RE2’s proven track…

Found in Robotics News & Content, with a score of 5.57

…our factories to train robots, optimizing workflows with unprecedented precision and reducing costs.” Delta Electronics, a manufacturing company in electronics and IoT-based smart green solutions, is using NVIDIA Isaac Sim, an extensible robotics simulation platform developed on Omniverse and OpenUSD, an open and extensible ecosystem for 3D worlds, to virtually integrate its demo production lines. It then generates physically accurate, photorealistic synthetic data for training computer vision models for its NVIDIA Metropolis-powered automatic optical inspection (AOI) and defect detection offerings. Pegatron, a Taiwan-based manufacturer and service provider, is deploying an NVIDIA Metropolis multi-camera workflow and launching a new suite of…

Found in Robotics News & Content, with a score of 5.57

…have shown that it is possible to improve the precision of the estimates of material properties by as much as 20 times. We have also validated this system’s predictive capability and accuracy enhancement on conventionally manufactured aluminum alloys and 3D-printed titanium alloys. This points to our method’s potential for digital manufacturing applications in Industry 4.0, especially in areas such as 3D-printing.” The findings will be published in the Proceedings of the National Academy of Sciences of the United States of America. Material Benefits From a Hybrid Approach The method, developed by the team of researchers from NTU, MIT and Brown,…

Found in Robotics News & Content, with a score of 5.57

…providing manufacturers with a portable solution that combines flexibility, precision, and speed, we are essentially putting a 21st century blacksmith shop in the backyard of any business that wants one.” Founded in 2019 by aerospace and automotive industry veterans, Machina Labs is a Los Angeles-based advanced manufacturing company. Enabled by advances in artificial intelligence and robotics, Machina said it is developing “software-defined factories of the future.” Machina Labs' stated mission is to develop modular systems that can be reconfigured to manufacture new products simply by changing the software, with minimal disruption to facilities or operations. RoboForming and the Machina Deployable…