Editors’ Picks

Found in Robotics News & Content, with a score of 2.89

…the gate, which includes organizational awareness of current trailer inventory that includes size, type and status, as well as additional information are critical. And Camera also noted that organizations must also focus on dwell time for trailers in the yard, which can help them significantly reduce costs. “Yard drivers and dispatchers or dock workers traditionally are very manual/paper intensive,” he said. “And finally, using a YMS for task management can eliminate manual processes for yard drivers, and can dramatically increase moves per hour and eliminate human error.” With more than one-fifth of the report’s respondents still managing gate processes on…

Found in Robotics News & Content, with a score of 2.86

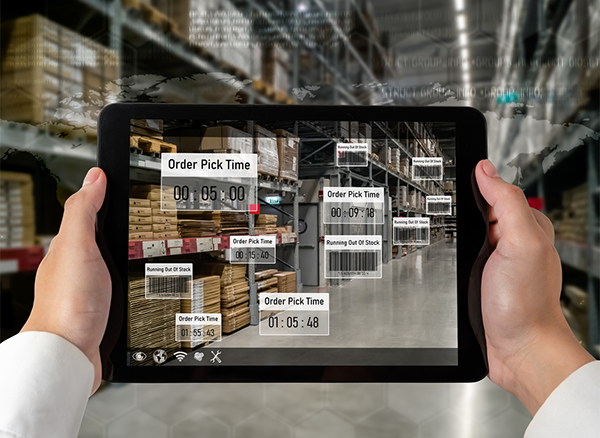

…This next-generation smart warehouse will increase productivity; enable automated inventory control, safety, and security within the facility; and save time and money for employees and customers.” “We are pleased Zyter has chosen Qualcomm Technologies’ IoT products for another IoTaaS commercial deployment with the smart warehouse for OneScreen,” said Sanjeet Pandit, senior director and global head of smart cities at Qualcomm Technologies. “To directly address the fragmented nature of the IoT industry, our unique Qualcomm IoT Services Suite is helping to bridge the gap for IoT service providers and entities looking to efficiently and effectively deploy smart solutions and is revolutionizing…

Found in Robotics News & Content, with a score of 2.86

…their own stand-alone e-commerce business with the geographic and inventory positioning capability to meet same-day/next-day delivery expectations, they’re asking 3PLs to help,” Lieb adds, noting it’s become the fastest growing part of the 3PL business in the last five years. “Last year, of the 3PLs I surveyed, almost 14% of their revenue consisted of e-commerce. The year before it was 18%.” “If a 3PL specializes in doing a certain service well, they can better scale their operations and offerings to price themselves to be profitable” Brian Gibson, Professor of Supply Chain Management, Auburn University Brian Gibson, professor of supply chain…

Found in Robotics News & Content, with a score of 2.85

…line sells more, how I scale production and manage inventory?” Scenario planning is currently done with old software and little automated hardware, but supply chain leaders want to do more of this. They need actionable data to make their supply chains more resilient. Another thing we've heard in the Link ecosystem is that data is siloed—how can we connect it? Nobody has the appetite to build a data-dumping project, and data fragmentation is a big problem. It can only be solved with a clear use case, visibility into inventory, and then a layer above that to be able to do…

Found in Robotics News & Content, with a score of 2.84

…test equipment, parts and components, hazardous materials, and retail inventory goods. Sarcos recently put the advanced teleoperation control system, including the SenSuit motion-capture controller, and Guardian XT robotic system, to work in a live tree-trimming demonstration at its headquarters in Salt Lake City, Utah. It said the product will be commercially available by the end of 2022. About Sarcos Robotics Sarcos said its technology is based on more than 30 years of research and development into mobile robotic systems to augment human performance. Its systems for enhancing safety and productivity include the Guardian S, the Guardian GT, the Guardian XO,…

Found in Robotics News & Content, with a score of 2.83

…to be easily and accurately restocked or returned to inventory. This significantly improves productivity and efficiency while allowing workers to interleave pick and put tasks. • Multi-Order, Multi-Tote Picking: LocusBots can easily accommodate a full range of picking containers. Mix and match different cartons and totes of all sizes to work with any pick process or workflow, further enhancing fulfillment productivity and throughput. • Bulk Item Picking: Easily pick larger quantities of goods for later sorting. • LocusBot Top-Off Auto-Charging: A sophisticated, dynamic auto-charging system ensures LocusBots are always charged, eliminating downtime. Locus’s proprietary software automatically recognizes lulls throughout the…

Found in Robotics News & Content, with a score of 2.81

…time and investments in warehousing and storage; order customization; inventory management; and individual pick, pack, and ship. Other obstacles include a lack of management support, too many variables in products, space and cost constraints, and inventory fluctuations. What is the current state of your organization’s pursuit of robots in your warehouse or DC? Source: Peerless Research Group Survey participants look ahead to more automation Of the survey respondents who plan to use robots, but don’t currently have them in place, 38% of respondents are in the education and knowledge-gathering stage; 22% are in the strategy and vision formulation stage; and…

Found in Robotics News & Content, with a score of 2.81

…complex environments. Geek+ added that its AMRs can organize inventory based on real-time demand and move shelves and pallets of ordered goods to picking stations, where employees will finalize the process guided by a user-friendly interface. In comparison with warehouses reliant on manual operations, the systems can improve picking accuracy and efficiency by 300%, claimed the company. In addition, Geek+ said it has developed systems for industries including e-commerce, apparel, retail, logistics, third-party logistics (3PL), pharmaceuticals, and manufacturing. It added that it has 300 global customers and has deployed more than 10,000 robots worldwide. R&D at HKSTP Geek+ said its…

Found in Robotics News & Content, with a score of 2.80

…provides the knowledge needed to reduce operations costs and inventory, and respond to clients quicker The adoption of machine learning and other AI technologies provides new insights into a wide range of aspects, including logistics and warehouse management, collaboration, and supply chain management. According to Artificial Intelligence in Logistics, a report by DHL and IBM outlined a number of technologies capable of doing that. Some of them include: Intelligent Robotic Sorting – an effective, high-speed sorting of letters, parcels, and palletized shipments AI-Powered Visual Inspection – taking photos of cargo using special cameras allows to identify damage and identify an…

Found in Robotics News & Content, with a score of 2.80

…footprint in close proximity to end consumers, utilizing more sustainable packing materials, and minimizing shrink and waste through smart inventory management, Fabric’s micro-fulfillment centers could lower last-mile emissions significantly.” Fabric said it plans to use its latest funding to expand its on-demand fulfillment platform across the general merchandise market and build a network of micro-fulfillment centers across major metro areas in the U.S. to make fast delivery scalable and profitable for retailers. The company said it support this stage of hypergrowth by also heavily recruiting for its world-class technology, commercial, and operations teams in Israel and across the U.S.

Found in Robotics News & Content, with a score of 2.79

…for a product platform that can pick items from inventory storage bins, induct items to sorters, or place items into outbound orders in this vision of the future. So, what’s holding this prediction back? After looking at adoption curves for technologies across many industries over the years, we find that it takes some time. When the people who need a new product meet it for the first time, a whole new set of needs and opportunities arise. A piece-picking machine may be able to pick most of the products in a warehouse at a reasonable rate without damaging or dropping…

Found in Robotics News & Content, with a score of 2.79

…palletizing cell. Source: NorthShore Care Supply Robots grow with inventory Fast forward to July 2021, when I toured the Green Oaks facility once again. The AMRs were still traveling through the aisles, associates were busy picking to the robots and moving product through the packing stations, and lift truck operators were moving pallets to replenish pick locations. I saw two big differences: Significantly more inventory was in the warehouse than in July 2020, and at the receiving dock, two associates were unloading cartons onto a powered conveyor from inside a shipping container. Those cartons were then directed to a robotic…