Editors’ Picks

Found in Robotics News & Content, with a score of 11.59

…to bring reliability and consistency to the combination of navigation, perception, and manipulation, we are excited to be launching an autonomous mobile robot (AMR) into the marketplace later this year. Our collaborative AMR will address the market’s need for greater payloads in material handling. Q: What else can we expect from IAM in 2020? A: We’re working with A.S. Watson Group to deploy a fleet of Swift™ robots at its Benelux e-commerce fulfillment center in the Netherlands. We’re also opening a state-of-the-art headquarters and Showcase Innovation Center in Pittsburgh, where we’ll showcase our solutions and research. Q: Will robots ever…

Found in Robotics News & Content, with a score of 9.07

…beyond floor-level, point-to-point transportation. In addition to the LiDAR-based navigation technology used in other Yale robotic solutions, the robotic reach truck uses a combination of 3D cameras and sensors to perceive its surroundings and perform at height. “These awards honor Thomas Edison’s emphasis on innovations with practical value, from the incandescent light bulb to improvements to the telephone,” says Mick McCormick, Director, Robotics and Automation, Yale Materials Handling Corporation. “The robotic reach truck shares this philosophy, specifically designed to address major challenges facing supply chains like sourcing and retaining labor, finding space for growing inventories and rising commercial real estate…

Found in Robotics News & Content, with a score of 9.69

…with a Performance Level D safety system, a high-level navigation system, and advanced braking. With this system, manufacturers can optimize their workflow, while still maintaining safety, by using a unique approach to achieving the optimal safety zone that allows for the use of thinner aisles and fewer unnecessary forced stops. Download our guide to get an in depth look at: How a Performance Level D safety system works and why you need one How robots operate efficiently in a highly dynamic environment How a properly implemented safety system reduces wear-and-tear on equipment and increases system reliability and safety Get the…

Found in Robotics News & Content, with a score of 5.65

…operating system, or ROS, which is largely related to navigation, localization and travel, much like a warehouse control system controls a conveyor or sorter. On top of that, the robot is continually observing warehouse conditions that might impact how it gets from Point A to Point B and learning from recently completed routes. “The robot is always making mental notes about the warehouse conditions so on its next trip, it might try a different route,” says Karen Leavitt, chief marketing officer for Locus Robotics. If you have more than one robot, they are sharing that information with the central server,…

Found in Robotics News & Content, with a score of 9.15

…of loads with one module and have fully autonomous navigation. “Waypoint’s Kingpin is the first of its kind dual-use module that enables Vector and MAV3K AMRs to automatically load and unload payloads as well as hitch and transport carts of all sizes,” said Waypoint Robotics CEO Jason Walker. “Now you don’t have to dedicate a robot for one task or another, with Kingpin you can do both. This combined with Numina Group’s RDS order fulfillment automation suite creates a powerful but easy-to-use solution to improve worker productivity and safety by reducing the heavy lifting.” Modex 2020 is scheduled to be…

Found in Robotics News & Content, with a score of 6.89

…Sensor Perception Accurate information from cameras, RADAR/LiDAR or satellite navigation is relied upon by ADAS systems to make safety-critical decisions. Now the blind spots caused by vehicle-road dynamics can be identified to determine which sensors to rely upon, when. For example, ensuring that a car driving over a speed bump is able to perceive a pedestrian, even if the camera vibrations prevent tracking. Vehicle Original Equipment Manufacturers (OEMs) can evaluate how sensors function when subjected to vibrations or changes in orientation, so they can cost effectively develop sensor fusion between road tests. “The perception of a camera mounted on a…

Found in Robotics News & Content, with a score of 5.57

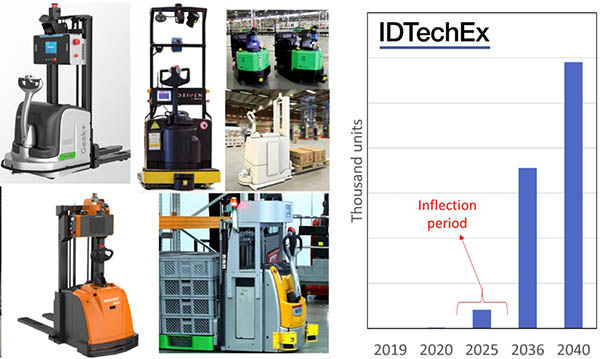

…This is due to the declining costs of superior navigation and the desire to build flexibility into robotic fleets. “Many new verticals, like hospitality, delivery, and infrastructure, will demand systems that do not require external physical infrastructure to move about. While AGVs will thrive in intralogistics for fulfillment, especially in greenfield warehouses, AMRs solve the challenges faced by many end-users by offering incremental automation that does not require a complete change of environmental infrastructure,” Whitton explains. In a major example of automation extending to new and important vehicle-types, the shipments of automated forklifts are set to grow from 4,000 in…

Found in Robotics News & Content, with a score of 8.01

…the technology is evolving towards more autonomous and infrastructure-independent navigation. We forecast that they will tend towards obsolescence and increasingly become confined to ever narrower market niches. Overall, we predict that their market will shrink by 50% in 2030 compared to the 2019 level. A bright spot for automated robots One very bright spot for automated robots is in goods-to-person automation within fulfillment centers. Special robot-only zones are created within warehouses in which these robot fleets move racks at high speeds to a manned picking station. The productivity gains are clear and proven. This is a fast-growing market space. The…

Found in Robotics News & Content, with a score of 2.83

…hours, as opposed to learning paper-based procedures or complicated navigation menus on wireless devices. Another key benefit of the system is that it generates detailed analytics about warehouse picking processes and inventory levels and movements. The Oklahoma City DC uses this data for various purposes, from metrics visibility for supervisors, to fine-tuning inventory positions, and knowing which workers are performing above average. By comparison to largely manual order picking processes where data collection can be overlooked or very basic, a mobile robotics platform is constantly generating data about what the robots did, what orders or materials they helped pick or…

Found in Robotics News & Content, with a score of 2.90

…however, remains daunting. Fig. 4: The temi robot’s ROBOX navigation system incorporates LiDAR, depth and RGB cameras, an inertial measurement unit, and proximity and time-of-flight linear sensors. This instrumentation allows the robots to perform 3D mapping, user detection and tracking, obstacle avoidance and path planning. Image courtesy of temi USA. “When designing robots, we always compare it to the human body—depth sensors and cameras instead of eyes, microphones for ears, motors for muscles and wires for veins and nerves,” says Frenkel. “That being said, even with these artificial body parts, it is very hard to teach a robot that a…

Found in Robotics News & Content, with a score of 6.56

…tracking, allowing users to use eyesight itself as for navigation and selection (like a mouse or a pointer) to activate context-sensitive menus and commands. Replica equipment adds realism The Greenlight Insights paper also states, “enabling close interaction and naturalistic control via hand tracking is an important milestone for any AR system. These developments show the importance of bringing content into arms reach and point to the need to develop an optical interface that can effectively engage our visual system to give accurate depth cues.” In conversation with Greenlight Insights Analyst Ben Delaney, Joel Breton, President of Sixense Studios, Sixense, observed,…

Found in Robotics News & Content, with a score of 6.14

…within the sophisticated software capabilities that provide three-dimensional mapping, navigation, inventory identification, and location accuracy. Indoor flights do not require FAA approval. Complexities of Managing inventory In our past article titled “Using the Right Technology For Your Inventory Management”, Matt Yearling, President & CEO, PINC, summarizes how Lora Cecere of Supply Chain Insights identifies how to effectively manage inventory in today’s dynamic business environment. In the video above, Matt Yearling chats to Lora Cecere about aerial inventory robots and autonomous warehouse drones for inventory management - Very much worth 12 minutes of your time! Related Article: Using the Right Technology…