Editors’ Picks

Found in Robotics News & Content, with a score of 5.98

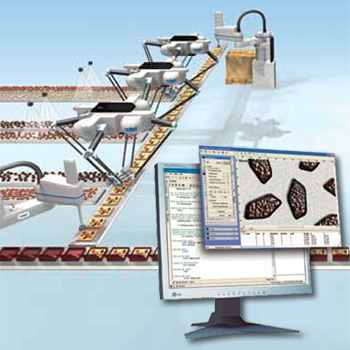

…can be easily changed, streamlined material flow, quality control, precision and consistency of parts, higher payloads, faster changeover, greater control of data, cleaner operations due to less human interaction and possibility most importantly, the ability to future-proof operations. Robotics with vision and conveyor control, along with flexible feeding mechanisms, play a large – and critical role – in many flexible manufacturing operations today. With flexible robots, manufacturers can now change over to the production of different products quickly - without the need for extensive re-programming or changing of tooling or equipment. Consider the cost of one employee. You have salary,…

Found in Robotics News & Content, with a score of 5.97

…trusted answers and advance the quality of life with precision medicines,” he added. “We are thrilled with the prospect of sharing in their vision to redefine the biopharmaceutical industry’s expectations for peptide manufacturing.” Spun off from Hewlett-Packard Co. in 1999, Agilent said it is a global leader in the life science, diagnostic, and applied chemical markets. The Santa Clara, Calif.-based company supports disease research, drug discovery, and pharmaceutical manufacturing and quality control. “Mytide and Agilent’s shared interest on leading the revolution on combining analytics and machine learning will accelerate our ability to bring our quick-turn manufacturing technology into the broader…

Found in Robotics News & Content, with a score of 5.96

…software, which digitizes the real-time flow of recyclables with precision and consistency. Better data provides opportunities to identify gaps in material capture, transparency on what recyclables are and are not recycled, and a basis for standardized measurement vital to improving the national recycling system. AMP recently expanded its partnership with Waste Connections Inc. its largest customer. Since late 2020, Waste Connections has booked or deployed 50 of AMP’s high-speed robotics systems on plastic, fiber, and residue lines, becoming the largest operator of AI-guided robotics in the industry. Last month, the company announced Vortex, its new system designed to identify and…

Found in Robotics News & Content, with a score of 5.96

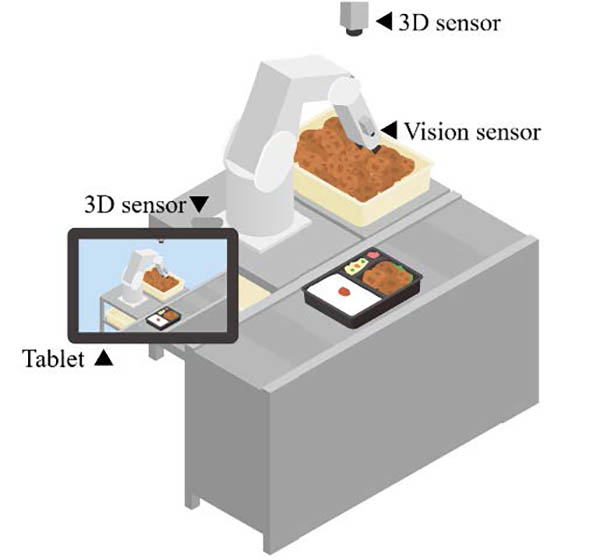

…new station uses its Maisart AI system, which includes high-precision speech recognition software, 3D sensors and cameras, to help its robots sort and arrange items. Maisart is an abbreviation for “Mitsubishi Electric's AI creates the State-of-the-ART in technology.” Workers will be able to dictate commands to the robot system either by voice or by using a tablet. The system is pre-programmed to complete tasks and is capable of self-adjusting if it is assigned new duties on the fly or faces obstacles, the company said. It is designed to be used by non-specialists. The company called it a “teaching-less” robot, given…

Found in Robotics News & Content, with a score of 5.95

…and artificial intelligence and machine vision are enabling greater precision. Photoneo today introduced its AI-based Depalletization and Delayering tools for automated pallet unloading. The Bratislava, Slovakia-based company said they can increase efficiency, reliability, and safety, as well as order-fulfillment accuracy for logistics businesses. “We trained the AI algorithms on huge datasets of images to provide customers with a robust and reliable solution for any type of fully automated pallet unloading,” stated Marcel Svec, vice president of strategy and products at Photoneo. “The algorithms can recognize any type of items and boxes, including different sizes, irregular shapes caused by damage, or…

Found in Robotics News & Content, with a score of 5.94

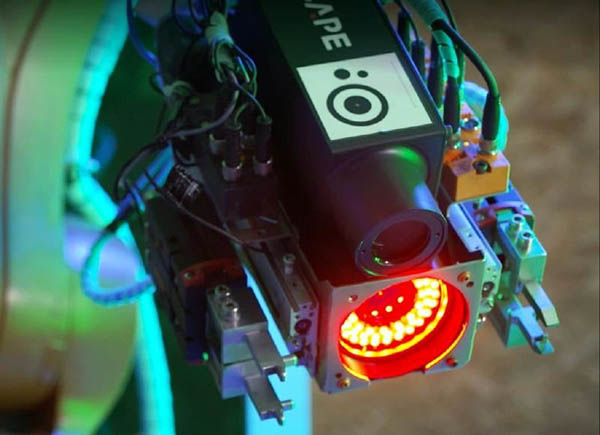

…member at Demek CNC OÜ. “In our opinion, the precision of their solution, as well as their reliability, is the future of the bin-picking market.” “Demek CNC’s core competences and projects fits to SCAPE Bin-Picking Solutions, which enable cobots and industrial robots to perform tasks that would not otherwise be able to automate efficiently and cost-effectively,” said Henrik K. Nielsen, channel manager at Scape Technologies. “The technology is used, i.e., for pick-and-place and bin-picking operations for automatic machine feeding, where benefits in the form of increased stability, reliability, and efficiency help to ensure high profitability in automatic handling of items,”…

Found in Robotics News & Content, with a score of 5.94

…robotics that enabled manufacturers to achieve greater efficiency and precision with the use of robotic arms on assembly lines. The innovations Engelberger introduced were a major factor in the rise of the Japanese auto industry, where the use of robotics was enthusiastically embraced in the post-war era. Engelberger was inducted into the U.S. Manufacturers Hall of Fame in 2009. The RIA named its prestigious annual award the Joseph F. Engelberger Award in recognition of his outstanding contributions to the field of robotics. Other honors Engelberger received over the course of his career include induction into the National Academy of Engineering…

Found in Robotics News & Content, with a score of 5.92

…interact with objects of varying sizes and weights with precision. These advancements unlock a multitude of new use cases, including adaptive cleaning in commercial buildings, food processing plants, passenger trains and airlines; agriculture harvesting, planting, and weed removal; assembly and pre-assembly operations with mixed-part selection and placement in manufacturing; residential and commercial building construction. Key distinguishing features of MoveIt Pro Release 6 In MoveIt Pro Release 6, the software also contains: Intelligent Runtime Decision Making Facilitates complex, multi-step operations Overcomes unexpected obstacles, environmental changes and error conditions Handles variations in object characteristics including size, weight and orientation Hardware Agnostic Design…

Found in Robotics News & Content, with a score of 5.91

…to 12 inches x 12 inches in size. Increased precision: The CBAM-2 features three added cameras. Streamlined maintenance: Automatic powder filling reduces fill-time to days, and bulk ink cartridges eliminate the need to refill ink frequently, allowing machines to run efficiently at a significantly greater duration. CBAM-2 machines will be available for customers beginning in Q3. In other news, Impossible Objects also announced that through a collaboration with BASF, its Model One and CBAM-2 printers will support BASF’s Ultrasint PA6 (polyamide 6) powder, allowing customers to 3D print high-performance carbon fiber-PA6 composite parts for the first time. “Our collaboration with…

Found in Robotics News & Content, with a score of 5.87

Beewise, the climatech precision robotics company on a mission to save bees, today announced an $80 Million Series C funding round. This brings the company's total funding to over $120 million. Using 24/7 monitoring and smart technology that increases pollination capacity and honey production, Beewise said its proprietary robotic beehive, the Beehome, automatically detects threats to a honeybee colony such as the presence of pests or pesticides, and it immediately defends against them. Robots to save bees Sacramento, Calif.-based Beewise said its robotic system responds to threats in real time and requires no human intervention. In addition to protecting and…

Found in Robotics News & Content, with a score of 5.86

…clean bore and reduces chip buildup to enhance machining precision and efficiency. “The Through-Spindle Coolant Kit will allow our customers to produce higher-quality parts at a faster rate than ever before,” Zelickman said. “By ensuring that coolant reaches the cutting tools exactly where it’s needed, the kit not only extends the life of the tools but also enhances the consistency and accuracy of every cut.” The user-installable system integrates with customers’ existing 1500MX mills. The kit comes with all the necessary components to add this capability to customers’ machines. Powered by a three horsepower, 220V single-phase motor, the TSC Kit…

Found in Robotics News & Content, with a score of 5.86

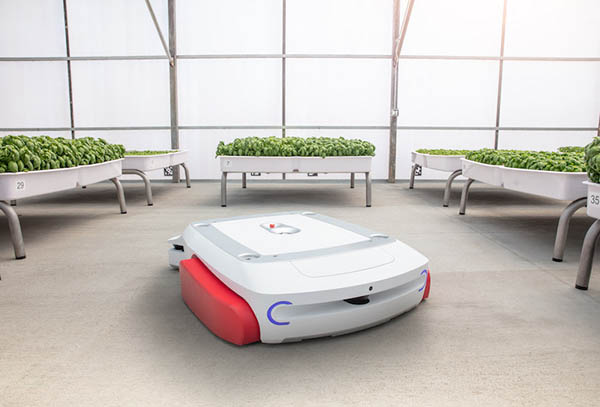

…process, from seed to store shelf, achieving levels of precision that are impossible through conventional farming.” The Silicon Valley startup claimed that it can help provide delicious, nutritious, sustainable, and local produce. Grover designed to optimize hydroponics Iron Ox said Grover is a key component of its broader farming ecosystem, a closed-loop system intended to optimize plant yield, reduce growth cycle times, and maximize crop quality. The company's team of roboticists, plant scientists, and engineers has applied artificial intelligence, machine learning, computer vision, and robotics to grow more with less, leading to less food waste and reduced greenhouse gas emissions.…