Editors’ Picks

Robot arms equipped with the right safety features can operate in close proximity to people. But not all collaborative robots are built for constant work alongside humans. The Association for Advancing Automation (A3) defines four major types of collaborative robots recognized by the ISO. Some primarily move autonomously, abiding by visual sensors telling the robots to slow down or stop if people get too close. Others are built with collision sensors that stop robot arms when they contact obstacles. And others still are guided by hand, either in operation or during programming. Yaskawa America Inc. Motoman Robotics Division (Yaskawa Motoman)…

Anyware Robotics

“All in all, it’s just another brick in the wall.” Pink Floyd’s classic from 1979 dives into plenty of other topics than robotics in 2024, but the underlying tie-in of bricks in a wall does spill over 45 years later. When FedEx first partnered with California-based Dexterity to develop a mobile truck loading robot in 2021, there was room for growth, improvement and evolution. Truck unloading is a tedious, physically-demanding and cumbersome task. Hence, the need for automation was apparent. But how do you go about automating a process with a high degree of variability? It doesn’t happen overnight. Multiple…

Dexterity

Design

End-user

Autonomous mobile robots (AMRs) have been heralded as a transformative force poised to supercharge productivity and efficiency across industrial automation. However, as adoption accelerates, there is a growing recognition that many deployments are failing to live up to their full potential. The dynamic, unpredictable nature of real-world warehouse, distribution and fulfilment environments is exposing critical limitations in traditional localization technologies. Overcoming this gap between an AMR's theoretical capabilities and its practical performance hinges on implementing a new class of robust, adaptable localization solutions. The constraints of legacy 2D laser scanners have become increasingly apparent, spurring the industrial automation sector's pivot…

Fox Robotics, an Austin, Tex.-based autonomous forklift manufacturer, recently announced a multi-year partnership with Walmart to deploy 19 FoxBot autonomous forklifts across four high-tech distribution centers. The companies also announced the potential for future deployments based on pending continued performance. After a 16-month proof of concept at its Brooksville, Fla. distribution center, Walmart announced that it also invested growth capital for a minority stake in Fox Robotics. FoxBot moves beyond picks milestones After the company announced its FoxBot surpassed 2.5 million picks in February 2024, Fox Robotics has now secured a major customer in the warehouse space. “As the leader…

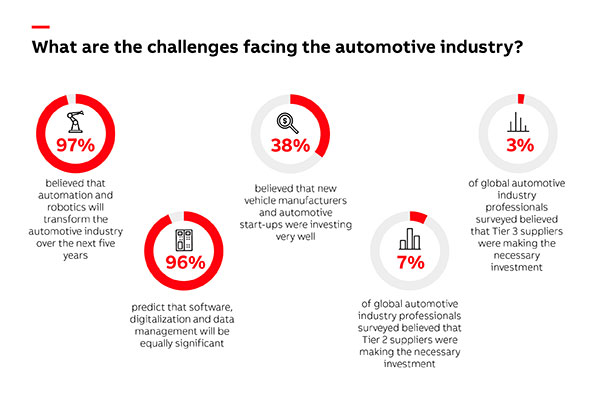

Industrial robot provider ABB Robotics, a division of ABB Group, recently released the results of its second annual Automotive Manufacturing Outlook Survey. The new global survey was commissioned by ABB Robotics and conducted by Automotive Manufacturing Solutions (AMS). The survey gathered opinions on a range of topics from nearly 400 industry experts, ranging from vehicle manufacturers and suppliers at all levels of management and engineering as well as other professionals throughout the automotive manufacturing world. Energy-efficient robots for manufacturers of all sizes ABB said almost all respondents (97%) believed automation and robotics will transform the automotive industry over the next…

Engineer

When people think of cobots, they usually picture people and robots working side by side in a shared space. But collaborative robotics also includes the fields of supervised autonomy and teleoperation. Plus One Robotics creates machine vision and AI computing systems for parcel picking applications. In addition to its AI platform PickOne, the company provides its customers with a remote supervision service called Yonder. Plus One describes Yonder as a human-in-the-loop automation software suite for robotic applications. Through its Yonder robotics-as-a-service (RaaS) offering, Plus One’s crew chiefs serve as remote supervisors who can step in 24/7 when automated systems need…

General-purpose robot provider Flexiv Robotics Inc. recently announced a deployment for window shutter manufacturer EsVata at its California factory. EsVata chose to integrate Flexiv’s Rizon 4 adaptive robot arm into their production line to automate the time-consuming task of sanding window shutters, which was previously accomplished by skilled manual labor. Paul Hsieh, EsVata founder, and Gavin Bomhoff, Flexiv on-site application engineer, with Flexiv’s Rizon 4 adaptive robot arm outfitted for sanding at EsVata’s factory. Source: Flexiv Robotics “Our commitment to quality led us to select the Rizon 4 from a sea of competitors,” said Paul Hsieh, founder of EsVata. “Its…