Editors’ Picks

If last year’s “Annual Warehouse and Distribution Center (DC) Equipment Survey” reflected the need to quickly ramp up on systems, this year’s survey still indicates a bullish outlook, albeit a more cautious one. With multiple years of strong economic growth, expanding e-commerce, and low unemployment, many DC organizations are weighing their next steps for keeping pace with flush economic times. Rather than rush forward with investments, this year more respondents seem to be pondering their next best moves, including turning to third-party logistics (3PL) providers for help. Peerless Research Group’s (PRG) annual survey, conducted in January of 2019, found that…

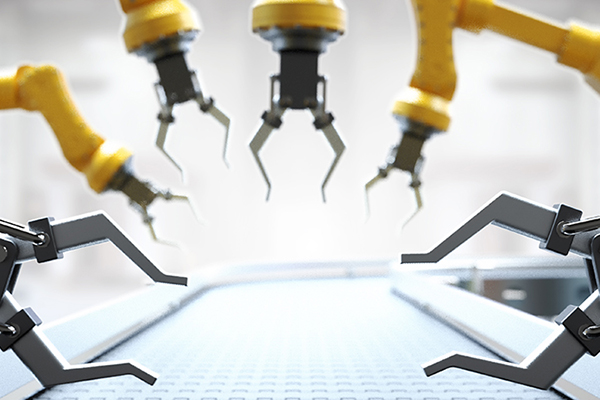

If you wanted to create the perfect mix of conditions to trigger the growth of a type of automated equipment for distribution center operations, you couldn’t do much better than the factors lining up in favor of robotics. E-commerce and omni-channel fulfillment are driving labor-intensive piece picking, and warehouse labor is increasingly difficult to find and retain. DC operators know they need to automate to reduce these challenges, but few operations are able to plunk down millions for traditional automation projects that carry long payback times and might be difficult to reconfigure. Enter a new generation of robots, based on…

You didn’t have to walk far at Modex 2018 to see some type of material handling robot edging by. There were many small, cart-sized autonomous mobile robots (AMR) moving around tugging carts or rolling shelves, collaborative robotic arms that do piece picking, robots with tilt tray sorter attachments or roller conveyor sections on top of them, and bigger robots to move heavy loads. For all the eye-catching arms, grippers, and navigation sensors hanging off these robots, it can be easy to forget how software-driven they are. Robotics vendors may stress features like grippers, or specific material handling tasks their bots…

Fetch Robotics (Booth B4835) announced it has expanded its VirtualConveyor family of autonomous mobile robots (AMRs) with the addition of CartConnect and RollerTop robots. CartConnect solutions allow the AMRs to pick up, transport and drop off delivery warehouse carts to any warehouse or manufacturing location. This lets human pickers stay in their pick areas, and lets the robots do the transport to locations such a pack/ship stations, explained Carl Showalter, Fetch COO, at a booth visit. The RollerTop robots have integrated active conveyor modules on the top of the units, which allows them to dependably hand off or receive material…

Just one year after its debut, the stationary piece-picking robots from RightHand Robotics (Booth B4087) for warehousing and fulfillment centers continue to evolve to address the individual unit handling needs of e-commerce and omni-channel retailers. “They’re ideal for reliably picking a wide range of variable items at high throughput rates from a tote delivered by an AS/RS or a conveyor,” said Vince Martinellli, head of marketing and products. “To make this happen, we use our RightPick AI—artificial intelligence—software.” The software overcomes the challenge that most robots face: hand-eye coordination. “They have an intelligent gripper, a vision system and software that…

If there were one clear-cut conclusion to be drawn from our “2018 Warehouse and Distribution Center (DC) Equipment Survey,” it would be that the outlook for spending is bullish. The percentage of respondents saying that they’re “proceeding with investments” reached its highest level in four years, and the percent of respondents saying that they’re “holding off” on material handling solutions shrank by 7%. However, the purse strings aren’t being held wide open across the board. A few subcategories saw tepid or declining indications, and generally, respondents seem more interested in specific types of material handling equipment, rather than large scale…

It’s tempting to copy the choices of distribution centers that have broken through to higher productivity after deploying automated materials handling. The pages of Modern are filled with examples of companies that have tapped solutions like mini-load shuttles, voice picking or goods-to-person robotics to achieve greater speed, labor savings and accuracy. So, why not just install some of that equipment at your DC and wait for similarly dramatic benefits? The short answer, say consultants involved with warehouse automation, is that replicating the path taken at another DC may turn out to be disappointing if the automation installed doesn’t support core…

The familiar technology stack of warehouse management systems (WMS) to manage transactions and inventory at the distribution center level and then hand order requirements down to the automation layer is not as simple as it used to be. With the complexities of e-commerce fulfillment, the need to orchestrate and optimize operations is driving the need for advanced execution software in the middle of the stack and for more optimization tools. In short, the DC tech stack has changed. It’s no longer just WMS on top, warehouse control system (WCS) software in the middle, and automated materials handling systems at the…

It’s time to begin automating your warehouse to keep pace with business. Either through growth in e-commerce or a restructuring of the distribution center network, many warehouses that used to do fine with mostly manual methods need automation to adapt to new requirements. That decision process for automation used to center on an analysis of historical demand patterns. But what happens when e-commerce sends assumptions around order mix and volume out the window? The answer, say providers of warehouse automation, is that the reasons why you automate begin to change. It’s less about raw efficiency in processing large batches of…

How digital supply chain management—the broad concept that Cloud-based systems, analytics and monitoring of goods, vehicles and other assets via the Internet of Things (IoT)—will improve the way supply chains run, is top of mind for many in logistics today. Also discussed under similar terms like digitalization or Industry 4.0, digital supply chain management spans multiple technologies and includes its fair share of buzzwords—but there is evidence it’s more than hype. According to MHI’s 2017 annual survey on next generation supply chains, 80% of respondents believe that the digital supply chain will be the predominate model within the next five…

Modex always delivers innovative new products, but at this year’s event, robotics captured much of the attention, from prominent mention in MHI’s industry report keynote, to new robotics vendors on the exhibit floor. Robots in distribution centers (DCs) aren’t new, but new vendors are coming on the scene, touting “mobile autonomous” technology, meaning that you don’t need to install special infrastructure on floors or ceilings for the robots to be able to navigate. One new example along these lines is IAM Robotics, which can pick from existing rack and shelves using onboard 3D vision technology, as written about in our…

In a booth press conference on Monday, KNAPP Logistics and Automation’s Kevin Reader, marketing director, discussed the company’s newest technologies, including the Pick-it-Easy fully automatic picking work cell. Robot-centric and ideal for high-quality picking of slow- to medium-moving items, the work cell is on display in Booth 3747. “The booth has a sample work cell configuration of the Pick-it-Easy Robot, fully integrated with warehouse management system (WMS), warehouse control system (WCS), conveyor and pocket sorter,” he said, noting that KNAPP recently completed a pocket sorter installation for REI. “This exhibit is one of a series workstations we offer, centered around…