Editors’ Picks

Found in Robotics News & Content, with a score of 31.17

…a press conference at the Formnext 2019 trade fair, Stratasys announced its Rail Industry Solution to help passenger trains—from long-haul to urban metros—runs on time more frequently and potentially save thousands of euros a day. By using its ULTEM 9085 resin and Antero 800NA material with Stratasys Fortus 3D printers for production, rail operators will be best positioned to leverage additive manufacturing for the production of spare parts on demand that meet strict government certification requirements for smoke, fire and toxicity. Both materials have passed the European Union’s Rail Standard, EN45545-2. The Stratasys ecosystem of customers and partners benefiting from…

Found in Robotics News & Content, with a score of 30.27

…it has made a formal, non-binding offer to acquire Stratasys Ltd. for $18 per share in cash. The company previously said it views Stratasys as a “strategic, complementary asset in the relatively mature polymer-based AM [additive manufacturing] market segment.” “We have great respect for Stratasys’ business, including Chief Executive Officer Dr. Yoav Zeif, who we believe is the architect of Stratasys’ recent positive momentum,” stated Yoav Stern, chairman and CEO of Nano Dimension. “Together, Nano Dimension and Stratasys can offer an increasingly exciting set of solutions for customers while becoming better positioned to compete in the AME [additively manufactured electronics]…

Found in Robotics News & Content, with a score of 29.34

SME and Stratasys have announced the winners of their co-sponsored 2019 Additive Manufacturing Competition, held during the 55th annual SkillsUSA National Leadership and Skills Conference in Louisville, KY, in late June. Six teams—three high school and three college teams—received top honors for the designs they created during the three-day contest. SME and Stratasys have collaborated on the contest for the past 5 years, designing the challenge to educate high school and postsecondary students about additive manufacturing technologies while providing them with real-world, hands-on experience using the technology. “Every year the participants in our SkillsUSA Additive Manufacturing Competition impress us with…

Found in Robotics News & Content, with a score of 24.29

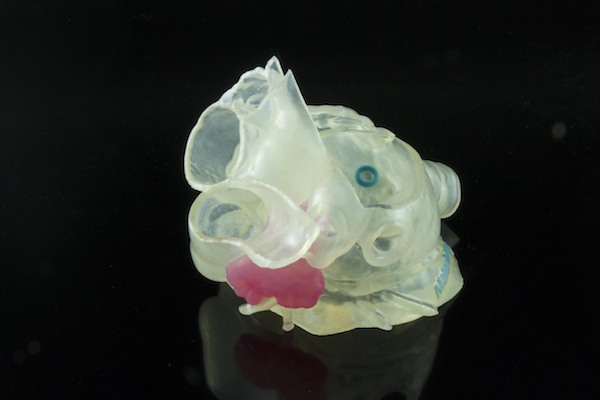

…their hardware for use in these applications. In November, Stratasys announced that it had expanded the suite of printers and materials that Materialise had validated with Mimics inPrint to include the J750 and J735 printers and the desktop Objet30 Prime 3D Printer. The J750/J735 printers can create models using multiple textures and both hard and soft materials, as well as multiple colors. “This takes the physician from having to evaluate 2D images in the form of X-rays or CT scans and bringing that information into a 3D world,” says Mike Gaisford, director of healthcare solutions at Stratasys. “The possibilities are…

Found in Robotics News & Content, with a score of 23.67

…for the medical staff. This week, 3D printer maker Stratasys launched a project to help fill the gap in PPE production. The company's first goal is “to deliver an initial 5,000 [face] shields to critical need locations over the next week.” Calling for 3D Printer Operators to Produce Medical Face Shields Disposable face shields, such as those from the vendor Safety Supply America, are designed to protect medical staff from infectious droplets and toxins when treating patients. “Stratasys is rapidly scaling its efforts to print both reusable and disposable face shields on dozens of FDM 3D printers located in Texas,…

Found in Robotics News & Content, with a score of 23.19

…a founding member of America Makes, in conjunction with Stratasys Inc., Wichita State University — National Institute for Aviation Research (NIAR) and the National Center for Advanced Material Performance (NCAMP), and Lockheed Martin Missile and Fire Control, with NIAR research funding from the Federal Aviation Administration (FAA). “The significance of this project for the aerospace industry is tremendous,” says Tracy L. Albers, Ph.D., president and CTO, rp+m. “Our open collaboration with the FAA-funded effort to develop a framework for advanced polymer-based additively manufactured materials, in this case, ULTEM 9085, into the NCAMP process was incredibly successful. The project examined an…

Found in Robotics News & Content, with a score of 20.97

…real ABS material in a 100°C build chamber using Stratasys SR-30 soluable supports allows dimensional accuracy and precision typically associated with higher-grade and more expensive industrial 3D printers, Makerbot officials said. Specifically, they claim METHOD X can print parts that are up to 26% more rigid and up to 12% stronger than modified ABS formulations used on most existing desktop 3D printers. In addition, the 100°C Circulating Heated Chamber significantly reduces part deformation, producing parts that are less susceptible to warping or cracking and that sport an optimal surface finish, they added. “The combination brings manufacturing closer to the desktop…

Found in Robotics News & Content, with a score of 18.03

…the hobbyist 3D printing market, MakerBot, now owned by Stratasys, is looking to blaze new ground with its latest offering by bridging the gap between desktop and industrial 3D printing. The newly launched Method, touted by the firm as the first performance 3D printer, is a wholly new platform, designed from the ground up to meld industrial 3D printing capabilities like dimensional accuracy and high-speed output with the user experience and reasonable price points that defined early MakerBot models. Method, priced at $6,499, is aimed at professional design engineers along with the education market, both of which are hungry for…

Found in Robotics News & Content, with a score of 16.63

…State of Texas more than 60,000 printed face mask kits, each with replaceable filters that extend its usable lifecycle. Stratasys and 3D Systems, two leading 3D printer makers, also have ongoing initiatives to supply PPE to hospitals and medial institutions. These are also augmented by other efforts from academia and individual makers. For more, read “3D Printing Pumps Out Essential PPE” and “Academia Pitches in to Make PPE.” 3D printer maker Essentium shifted production in Texas to manufacture face mask kits, each outfitted with replaceable filters to extend its lifespan. Image courtesy of Essentium.

Found in Robotics News & Content, with a score of 15.99

MakerBot, a subsidiary of Stratasys, joins the Google for Education Integrated Solutions Initiative to deliver a 3D printing experience for teachers and students. The MakerBot Cloud integration with Google For Education provides teachers with familiar tools as they get started with 3D printing with their students. The MakerBot Cloud platform, MakerBot’s print preparation and management solution, is now integrated with Google for Education to provide educators and students with an easy 3D printing workflow. One of the key challenges that teachers face when using 3D printers as a learning tool is how to best manage student submissions and print files.…

Found in Robotics News & Content, with a score of 13.44

…bring improved productivity and connectivity to additive manufacturing operations. Stratasys announced it created an authorized materials partner program to expand the range of high-performance polymers available to manufacturers using Stratasys’ fused deposition modeling process in 3D printing applications. Solvay has been selected to help launch the program. Jabil inked an additive manufacturing agreement to supply parts to Renault F1 Team. Through the Jabil Additive Manufacturing Network, Renault F1 Team will gain access to quality parts. Jabil wasn’t the only one with racing news. Stratasys announced it inked an agreement with Arrow Schmidt Peterson Motorsports, which competes in the NTT IndyCar…

Found in Robotics News & Content, with a score of 13.44

…around the world. Last year, the company deployed the Stratasys Infinite Build printer at its Research and Innovation Center in Detroit. The Shelby Mustang GT500, which will be unveiled at the North American International Auto Show in January, will include two 3D-printed brake line brackets, and the Chinese F-150 Raptor will include a 3D-printed interior component. Ford also uses five different 3D-printed tools at its Michigan Assembly Plant, where the Ranger is built. Ford is also using augmented and virtual reality to simulate assembly lines so that it can optimize production while ensuring production line workers are safe and can…