Editors’ Picks

Found in Robotics News & Content, with a score of 8.73

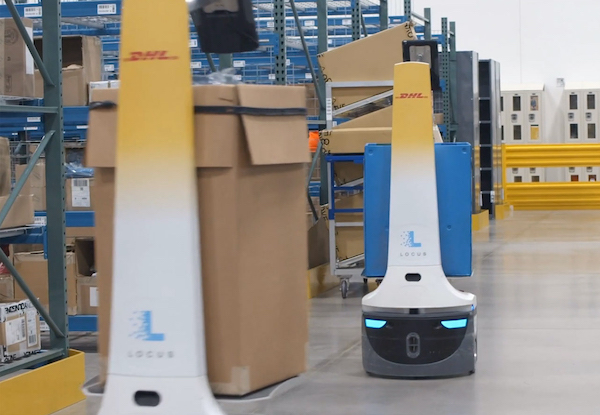

…movement and order-fulfillment productivity. The company said its hardware and software can also reduce operational costs and improve workplace ergonomics. Locus said that more than 100 of the world's top brands, retailers, third-party logistics providers (3PLs), and specialty warehouses have deployed its award-winning systems at over 250 sites. It recently announced that DHL Supply Chain will deploy 5,000 Origin robots across multiple sites. At Automate 2023 in Detroit next week, Locus Robotics will exhibit at Booth 4432. For more coverage of Automate, visit Robotics 24/7's special coverage page.

Found in Robotics News & Content, with a score of 9.18

…the operations running 24/7, but also provides benefits like ergonomics, safety, and the flexibility to handle the variance associated with seasonal shipping schedules.” FedEx is a key Plus One customer The company highlighted that FedEx is using 12 new Yaskawa induction systems that take advantage of Plus One's software at its FedEx Express Hub in Memphis, TN. FedEx had previously installed four other Plus One systems at the facility. Additionally, Plus One successfully introduced its mixed depalletizing systems at the FedEx Reno, NV facility. Plus One said its mixed depalletizing systems allow for easier, more efficient movement of cases from…

Found in Robotics News & Content, with a score of 7.64

…technology awards, the company said it can increase order fulfillment; lower operational costs; and improve workplace quality, safety, and ergonomics for workers. Supporting more than 100 of the world’s top brands and deployed at over 250 sites around the world, Locus Robotics said it enables retailers, third-party logistics providers (3PLs), and specialty warehouses to efficiently meet and exceed the increasingly complex and demanding requirements of today’s fulfillment environments.

Found in Robotics News & Content, with a score of 4.91

…firms is that labor shortages, the need to increase ergonomics and safety, and consumer expectations of accelerated deliveries have contributed to demand. At the same time, as much as 75% of warehouses and distribution centers in North America are reportedly not yet automated. More than 60 AMR providers offer to fill that demand, but several analysts told Robotics 24/7 that very few of them are currently profitable. Consolidation continues Amazon.com purchased Kiva Systems for $775 million in 2012, reserving its platforms for internal use only and helping to create the category by showing the “art of the possible” and forcing…

Found in Robotics News & Content, with a score of 8.14

…LED strip and 45-degree inclined touch panel provide an ergonomic operator experience, said Stäubli. These can increases user acceptance and ease integration, it added. For safety, the PF3 is equipped with a 360-degree human safety scanner, five emergency stop buttons, a collision avoidance sensor, and an LED strip that communicates the AGV’s status. Accessories include a table, stations for EU and U.S. pallets, and a remote control. Stäubli to show rugged robot at Automate Stäubli said it built the robot on its patented drive unit. The AGV is “constructed of industrial-proof components, delivering outstanding performance in terms of productivity as…

Found in Robotics News & Content, with a score of 12.90

…3D representations of the infrastructure, plant, machinery, equipment, human ergonomics, safety information, robots, automated guided vehicles (AGVs), and detailed product and production simulations. These technologies will help FREYR to meet surging demand for high-density, cost-effective battery cells for stationary energy storage, electric mobility, and marine applications, said the companies. Amid growing worldwide sustainability initiatives and the rapid electrification of transportation, the battery industry will grow to $400 billion by 2030, projected McKinsey & Co. Battery cell manufacturing is a critical step in the battery value chain, with manufacturers investing billions of dollars in new battery-cell plants to meet this new…

Found in Robotics News & Content, with a score of 8.33

…In addition, the supplier said its AMRs can improve ergonomics and overall workplace quality. Following the initial deployment at its warehouse in Tiffin, Ohio, Concordance is now in the process of rolling out the robots to 10 more sites across the U.S. Locus promises warehouse efficiencies “Locus's innovative multi-bot approach, dynamic flexibility, scalability, and fast ROI will help Concordance to consistently exceed their customers' expectations,” said Rick Faulk, CEO of Locus Robotics. “Our LocusBots are designed to improve all aspects of a warehouse picking, sorting, and returns while seamlessly meeting the increased demand of medical supplies and other healthcare needs.”…

Found in Robotics News & Content, with a score of 8.12

…the benefits of AMRs. They include delivering a more ergonomic working environment and improving efficiency, all while maintaining accuracy. Marseille, France-based CEVA Logistics has its U.S. headquarters in Jacksonville, Fla. The third-party logistics provider (3PL) offers a range of customized systems and air, ocean, ground, and finished vehicle transport in 170 countries and has 110,000 employees at more than 1,300 facilities. With pro forma 2022 revenue of $18.7 billion (U.S.), the unit of CMA CGM Group has also worked with Berkshire Grey, Kodiak Robotics, and Locus Robotics. CEVA Logistics deploys G2P systems CEVA Logistics said its 50,000-sq.-m (538,195.5 sq. ft.)…

Found in Robotics News & Content, with a score of 8.83

…be a creative and simple way to improve the ergonomics, speed, and range of induction of its tSort system. The system allows an operator to induct to multiple levels of our AMR sortation from a single station at induction. The Induction Lift eliminates the need for pre-sorting of items and allows for a larger, more efficient batch pick process upstream of the order sortation process, the Raleigh, N.C.-based company said. This system allows customer to stack the tSort AMR sortation system in up to 5 levels when used in tandem with Tompkins’ existing automated order container removal and replacement AMR,…

Found in Robotics News & Content, with a score of 13.75

…reflect the priorities of operational efficiency, operator productivity, and ergonomics, said Nedre Vats, Norway-based company. “Businesses today need to optimize their picking process if they are to meet evolving customer demands, but in order to achieve this, warehouses must be equipped with the tools that will enable their employees to work productively and safely,” said Carlos Fernandez, chief product officer at AutoStore. “This is why we're excited to offer FusionPort and FusionPort Staging, which will enable businesses to best serve their staff while leveraging the world-class technology that AutoStore is known for,” he said. FusionPort, FusionPort Staging designed for easy…

Found in Robotics News & Content, with a score of 4.88

…accuracy, higher warehouse productivity, lower operational costs, and less ergonomic issues,” he said. Rochester Hills, Mich.-based FANUC America is a subsidiary of Japan-based FANUC Corp. The company said it provides CNC systems, robotics, and ROBOMACHINEs, as well as expertise to help manufacturers maximize reliability and profitability. FANUC to demo growing CRX cobot line FANUC claimed that its expanded series of CRX collaborative robots can run for eight years without maintenance. Interactive programming enables users to teach points using hand guidance or a Tablet TP (teach pendant) with drag-and-drop icons, said the company. The latest CRX cobots complement FANUC’s existing lines…

Found in Robotics News & Content, with a score of 6.85

…industry and technology awards, the company said its system can reduce operational costs and improve workplace quality, safety, and ergonomics. Supporting more than 100 of the world’s top brands and deployed at over 250 sites around the world, Locus said it enables retailers, 3PLs, and specialty warehouses to efficiently meet and exceed the increasingly complex and demanding requirements of today’s fulfillment environments.