Editors’ Picks

Found in Robotics News & Content, with a score of 0.97

…with many well-established industrial solution providers such as ABB, GE, Siemens, and Honeywell, and bring AI into brownfield deployment, lowering upfront cost and the barrier to adoption. Through their partnership with system integrators and regional distributors, these startups have also ventured into Europe, South Korea, and Japan. “The high labor cost and the quick time-to-market have driven U.S. manufacturers to be more aggressive with the adoption of industrial AI solutions. This has given birth to pure-play AI players in the US, and as such, keeps the US to be the global leader in industrial AI solutions. Over time, however, we…

Found in Robotics News & Content, with a score of 0.65

…the relevant data, Inkenbrandt says. A company such as GE, Boeing or anyone that needs tight product control—including where and how they’re manufactured—uses the Identify3D solution to specify what assets and processes should be tracked. This metadata is then encrypted together with the relevant files and placed within a secure digital container. Only someone with the correct license key can access the data within this container. Like Materialise, Identify3D is partnering with machine tool builders. Yet Inkenbrandt says DRM goes much deeper. It might pull raw material suppliers into the loop, as well as quality control providers, design and manufacturing…

Found in Robotics News & Content, with a score of 0.94

…says Rochak Sharma, senior director, Predix product development, at GE Digital. “Not only are they able to gather the data, but they also convert that data into meaningful insights by using their data processing and analysis abilities.” Although smart sensors have been in play for years, technology developers are still sorting out how sensing devices fit into the IoT environment. That said, a number of visions have surfaced. One such view anticipates an inclusive, global fabric. “We expect the system to consist of many smart sensors that interact locally with each other—we call this the ‘extreme edge level’—but also with…

Found in Robotics News & Content, with a score of 0.41

…to collaborate on materials. The fact that companies like GE, Siemens, BASF and HP were represented at AMUG is sign that the larger manufacturing world is taking additive manufacturing seriously. Simulation software providers are also taking the technology seriously and working on the considerable challenges involved in predicting what will happen when a particular design using a particular material is 3D printed in a particular machine. “Part of what we've found from our customers is that it's not enough to have a best piece of simulation,” says Brent Stucker, director of additive manufacturing at ANSYS. “They want simulation in the…

Found in Robotics News & Content, with a score of 1.81

…verticals. The Fast Radius team is headquartered in Chicago and includes senior leaders from McKinsey & Company, Amazon, PayPal, GE and Blue Origin. Also participating in the Fast Radius Series B financing were previous investors Jump Capital, Skydeck, and Hyde Park Venture Partners. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 0.36

…of the Xometry network considerably. “Companies like BMW and GE were customers of ours before they became investors,” says Bill Cronin, chief revenue officer, Xometry. “But we also work with a wide range of young businesses, design and engineering firms in the midrange. We don’t have a minimum cost for an order. You can order a single part for as little as $5.” Early this year Xometry launched an initiative dubbed Xometry Supplies, making it easy for the 2,500+ manufacturers in its network to acquire the Aluminum 6061-T6, tools and supplies they may need after accepting a job. With this,…

Found in Robotics News & Content, with a score of 0.43

…aerospace and other industries. Giants such as HP and GE have launched large-scale metal printing efforts, but other companies have focused on smaller units that can be used for design and prototyping, as well as low-volume runs of metal production parts, tooling and molds. “Metal printing has been one of the best growth stories in 3D printing, and I think that is because current powder bed technologies are uniquely suited for advanced manufacturing,” says Kevin McAlea, executive vice president and chief operating officer, Healthcare, at 3D Systems. “We can process standard alloys and achieve excellent properties and address some key…

Found in Robotics News & Content, with a score of 8.84

…was closely followed by 3D Systems, Desktop Metal and GE Additive in overall rankings. Newcomer Desktop Metal took the overall top spot in innovation. The Additive Manufacturing Platform Ranking competitive assessment ranked 10 major vendors of the technology—3D Systems, Carbon, Desktop Metal, Digital Alloys, EOS, ExOne, GE Additive, HP, Renishaw and Stratasys—using ABI Research’s innovation/implementation criteria framework. Each vendor was analyzed based on a combination of AM technology process, material science, software, process and application adaptability, go-to-market strategy, revenue and bookings, availability, customer references, partnerships, cost and channel strategy. To qualify as an additive manufacturing platform vendor, the company had…

Found in Robotics News & Content, with a score of 1.92

…manufacturing, the company says. Last year the company joined GE Additive’s Manufacturing Partner Network and later became a founding member of MIT’s Center for Additive and Digital Advanced Production Technologies (ADAPT)—a consortium focused on scaling new manufacturing technology through research, education, actionable insights and an MIT-based ecosystem that pairs industry and academia. “Additive manufacturing has moved well beyond this worn-out notion that it has to prove its worth—we’ve seen firsthand its maturation over the years and have literally 3D printed millions of parts during that time,” says Protolabs’ president and CEO, Vicki Holt. “We know it’s an extremely valuable prototyping…

Found in Robotics News & Content, with a score of 1.14

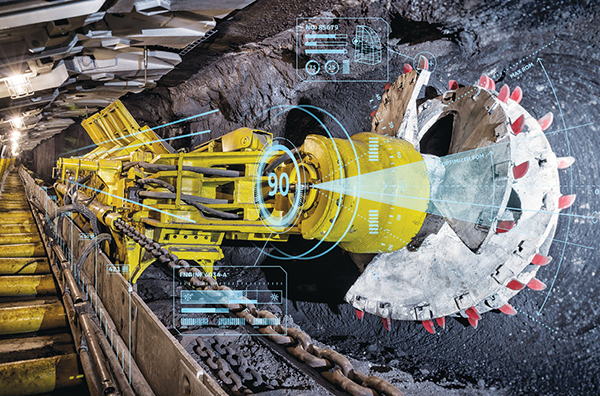

…lead from 2017 through 2022. Key players include Bosch, GE, Hitachi, Honeywell and Rockwell Automation. Increasing Product Availability The underlying architecture of a preventive maintenance model is fairly uniform. The analytics usually reside on a host of IT platforms, but these layers are systematically described as: data acquisition; data transformation—conversion of raw data for machine learning models; condition monitoring—alerts based on asset operating limits; asset health evaluation—generating diagnostic records based on trend analysis if asset health has already started declining; prognostics—generating predictions of failure through machine learning models, and estimating remaining life; decision support—recommendations of best actions; and human interface…

Found in Robotics News & Content, with a score of 0.94

…Siemens, in addition to AR and VR deployments from GE, Boeing, and Honeywell, among others, demonstrate this growing momentum, though the aforementioned challenges are hindering scalability. “The enormous benefits that wireless technologies can help achieve, including predictive maintenance, condition monitoring, big data analytics, more flexible workforces, efficiency improvements, safety enhancements, and many others will combine to produce increasing financial and production incentives that cannot be avoided,” said Zignani. “Wired technologies are simply not adequate to address all the multifaceted needs of the varied devices that will make up the IIoT and will be far too costly to implement. However, in…

Found in Robotics News & Content, with a score of 0.75

…layer palletizing at L’Oreal; mobile robots in manufacturing at GE Healthcare and Whirlpool; a piece picking robot in order fulfillment at Rochester Drug; a collaborative mobile robot from Locus Robotics at Quiet Logistics, and robotic distribution at Medline. In the March issue of Modern, we are featuring DHL Supply Chain’s strategy for mobile robots in order fulfillment purposes, including its use of Locus. In fairness, you could argue that it’s probably been ten years since Kiva first exhibited at one of our trade events. How is this different? I think it’s different in two important ways. The first is the…