Editors’ Picks

Found in Robotics News & Content, with a score of 3.35

…one type of robotics to accommodate different types of inventory and workflows, just like a DC might have more than one type of fixed automation. “I think the future involves distinguishing, within the four walls of your DC, what is the best fit type of automation for different segments of inventory,” said Santagate. “Don’t try to force fit one solution into every segment or scenario.” Match robots to processes Scoping out an appropriate robotics solution requires a solid understanding of order profiles and expected throughput levels, dimensions, inventory days on hand, as well as considering labor availability and productivity expectations,…

Found in Robotics News & Content, with a score of 5.10

…capacity. If your order volume increases, so must your inventory. As orders continue to come in, you’ve got to carry more and more stock. After a certain point, you’re carrying too much inventory and it’s time for a new building, right? Maybe. Mike Myers of ODW Logistics extended the life of his building by increasing his team’s efficiency: more orders, same space. Joanne Hoberg, VP of Solutions and Engineering, NFI: “We reduced time to achieve performance objectives by 90% by minimizing time spent learning processes and the warehouse floor.” We’ve said it before, we’ll say it again: training time matters…

Found in Robotics News & Content, with a score of 4.98

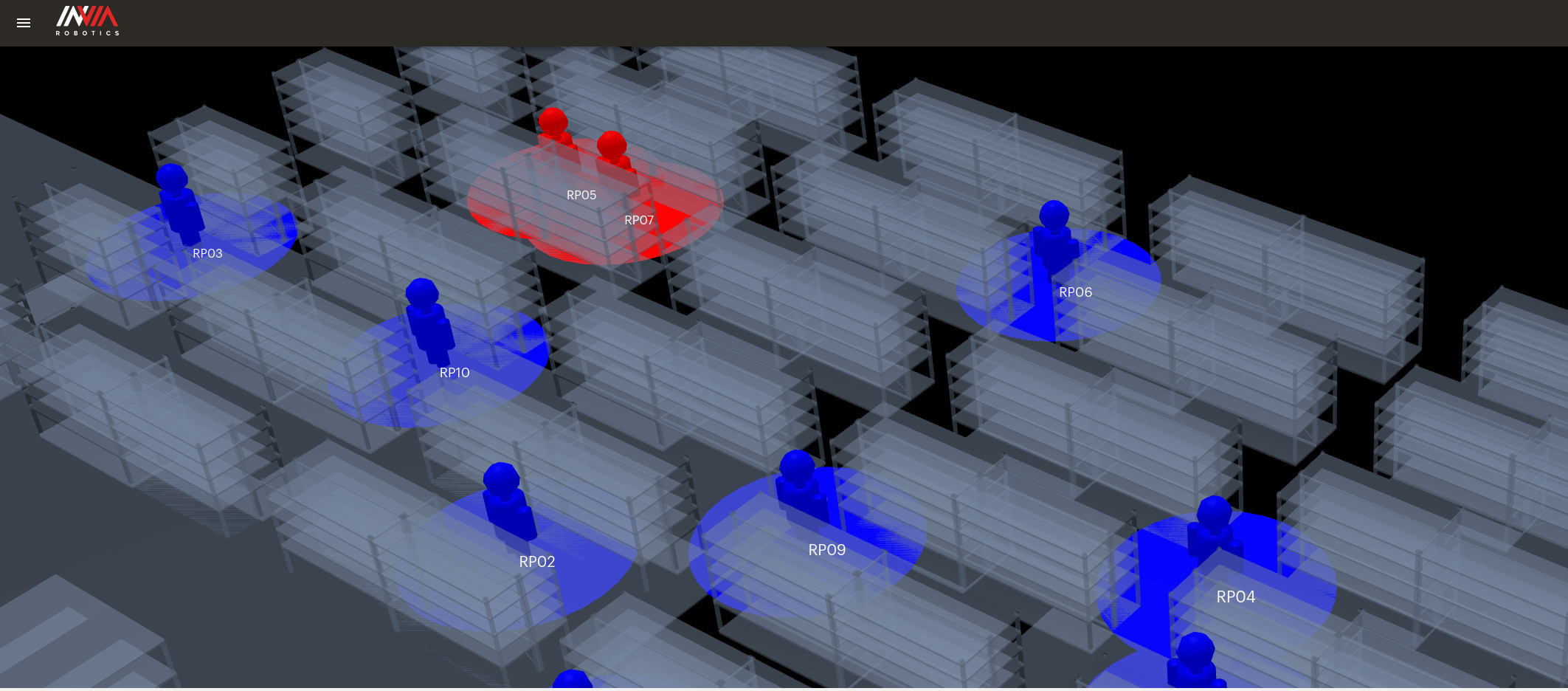

…where your associates will need to be based on inventory slotting and the order pool for the day. Incorrectly predicting zones results in overworking some associates while others wait around with nothing to do. Armed with knowledge of this challenge, we tackled the question: what if you could reap the benefits of zone picking without the challenge of analyzing inventory slotting, consumer demand and labor availability? Our solution: dynamic zoning. First, let’s understand the methodology we consider behind using static zones within a warehouse. Why are zones used? In order to meet SLAs and maintain profitability, there is a constant…

Found in Robotics News & Content, with a score of 5.35

…picking. GreyOrange’s Ranger GTP autonomous mobile robots (AMRs) bring inventory to warehouse associates at a picking station. The company's GreyMatter software orchestrates robots, people, and inventory for fulfillment in distribution centers and warehouses. GreyOrange has core operations in the U.S., Singapore, Germany, Japan, and India. Orlando, Fla.-based Tompkins Robotics’ tSort is a modular materials handling system whose AMRs can deliver a wide range of items and parcels to consolidation points. The integration between GreyMatter AI and Tompkins Robotics' warehouse execution software (WES) is key to making the joint offering work, said the companies. The “zero walk” combination of these products…

Found in Robotics News & Content, with a score of 4.86

…storage can enable customers to store four times the inventory in the same space or all of their existing inventory in 25% of the space. AutoStore systems serve markets including e-commerce, grocery, industrial, and healthcare in warehouse, retail locations, or micro-fulfillment centers. It recently unveiled an innovation hub in Norway and partnered with Asian-American grocer H Mart and Bastian Solutions. “We view AutoStore as a foundational technology that enables rapid and cost-effective logistics for companies around the globe,” stated Masayoshi Son, chairman and CEO of SoftBank Group. “We look forward to working with AutoStore to aggressively expand across end markets…

Found in Robotics News & Content, with a score of 2.69

…retrieved, the robots work in a goods-to-person framework, moving inventory into position to fuel order fulfillment and other logistics processes. By using the HAIPICK system, customers can realize warehouse automation transformation in a week, increase storage density by 80% to 130%, and improve operational efficiency by three to four times, claimed HAI Robotics. HAI Robotics added that it is continuing to conduct research and development to perfect its products and expand its customer portfolio. Last year, it launched the world’s first double-deep ACR, carton-picking ACR, telescopic lift ACR, and laser simultaneous localization and mapping (SLAM) ACR. The company also said…

Found in Robotics News & Content, with a score of 2.23

…to deliver lineside supplies on a just-in-time basis. When inventory on a conveyor reaches a predefined level, sensors alert the robot’s fleet control software to dispatch the tugger to refill the supply. Once the tugger arrives at the consumption point, the software notifies the automatic trailers to deliver materials to the conveyor and load empty containers back onto the trailers via their own powered conveyor system. Once the exchange is complete, the software dispatches the vehicle back to the pickup point. Automatic trailers and conveyors then exchange empty containers for full containers, and the autonomous tugger is sent to a…

Found in Robotics News & Content, with a score of 3.21

…claimed that its end-to-end fulfillment capabilities now include goods-to-person inventory delivery, pick-and-place induction, the t-Sort robotic sortation, automated packaging, and the new xChange system. The t-Sort materials handling system consists of autonomous mobile robots (AMRs) that sort a wide range of items and parcels to consolidation points. Typically, a unit-sorter system requires a human associate to manually sort items from an accumulation chute to unique order containers and place the containers onto a takeaway conveyor. By contrast, xChange allows most orders to be sorted directly into an order container, and the robotic sortation system automatically removes and replaces the container.…

Found in Robotics News & Content, with a score of 4.47

…(AS/RS), and warehouse management system (WMS) software that manages inventory, labor and warehouse fulfillment. A key focus for WES has been to handle order release in a more dynamic or continuous fashion compared with static waves of work. However, WES is not a one-trick pony for “waveless” order fulfillment with automation. WES providers say the software orchestrates the overall flow of work across all resources and is increasingly employing artificial intelligence (AI) and machine learning. WES vendors have come into the market from two basic directions, explains Dwight Klappich, supply chain research vice president and fellow with analyst firm Gartner.…

Found in Robotics News & Content, with a score of 5.99

…efficient routes through the warehouse to take products from inventory to pack out. Later this year, Cargo Cove will add inVia Picker autonomous mobile robots (AMRs) to augment existing labor and further increase productivity and accuracy rates. Cargo Cove is a full-service logistics company, providing everything from same-day fulfillment to reverse logistics. The rapid rise in e-commerce, which was growing 12% a year before COVID-19 and is now forecast to add nearly $100 billion more than previous estimates every year through 2023, has created unprecedented demand for third-party logistics (3PL). It has accelerated Cargo Cove's initiative to use technology like…

Found in Robotics News & Content, with a score of 1.80

…importance of safety, particularly in public-facing environments. “If an inventory-scanning robot hits an employee stacking a shelf, that's an OSHA call, but what happens if it hits Grandma?” said Prather. “It's one of the big concerns for retail end users.” Still, despite different use cases, adoption by multiple industries could lead to more direction for developers. “What do we want out of the technologies? My needs in a FedEx operation are different than what manufacturers or retailers may want, but we use similar mobile robots,” Prather said. “We can flip the script from robotics manufacturers just trying to sell stuff.”…

Found in Robotics News & Content, with a score of 3.18

…. About AutoStore Founded in 1996, AutoStore claims it is the inventor of cube storage automation – the densest product/inventory storage solution in existence—which it continues to develop. The company’s goal is to marry software and hardware with human abilities to create the future of warehousing. AutoStore has installed almost 600 systems in over 30 countries over a wide range of industries. All sales are designed, installed and serviced by a network of qualified systems integrators, which AutoStore calls “partners.” The company’s headquarters is in Nedre Vats, Norway, with offices in Oslo, the U.S., the U.K., Germany, France, Spain, Japan,…