Editors’ Picks

Found in Robotics News & Content, with a score of 23.84

…make quick physical prototypes to a solution for short-run manufacturing, bespoke offerings and complex parts that just can’t be economically made via traditional methods. “By 2030, the number of production-ready additive manufacturing platforms that ship each year will increase more than tenfold (more than US$325 billion in hardware and related systems revenue),” according to ABI Research’s white paper: The Industrial Revolution, the Top Trends and Takeaways from Hannover Messe 2019. “These systems will produce more than US$360 billion worth of parts and end products each year (up from US$6.8 billion today) and nearly US$2 trillion in sum by the end…

Found in Robotics News & Content, with a score of 14.10

…its alliance with Siemens, and also launched its Digital Manufacturing Network. The integration of HP’s new Jet Fusion 5200 Series 3D printing solution with Siemens’ Digital Enterprise offerings enables industrial companies to bring 3D printed parts to market faster, more cost-effectively, more sustainably, and at higher volumes than ever before, according to the company. The solution combines HP’s 3D printing and 3D data platform, including its new HP Jet Fusion 5200 system, with Siemens Digital Industries Software including Siemens NX CAD/CAE, NX AM for HP Multi Jet Fusion, undergoing certification by HP for its Jet Fusion 5200 Series to be…

Found in Robotics News & Content, with a score of 22.45

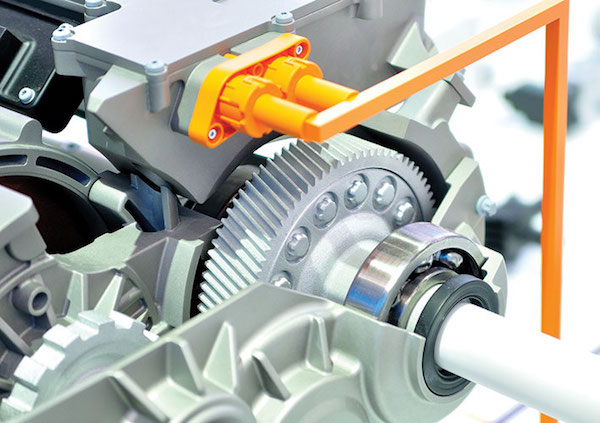

What do you get when you combine additive manufacturing (AM), generative design, and artificial intelligence (AI)? The answer might be found in Techniplas Prime, an e-manufacturing portal from Techniplas, a Tier 1 automotive supplier. “We've been practicing traditional lightweighting methods—for example, material substitution like replacing a metal structure with composites. But in the last one and a half year or so, our partnership with ParaMatters allowed us to incorporate generative design and topology optimization, so now, for projects awarded to Techniplas, we can look at all these lightweighting opportunities,” said Avi Reichental, CEO of Techniplas Digital. With online mechanisms for…

Found in Robotics News & Content, with a score of 23.68

With LulzBot 3D printers at the starting line, Nelson Racing Engines burns rubber, not cash. Watch as they unleash “race car power with street car manners” while saving thousands of dollars on prototyping via additive manufacturing. “Obviously in a shop like this you need a lot of tools…one of the tools we have that’s been amazing for us lately is the 3D printer we have from LulzBot.” —Tom Nelson, Builder and Fabricator at Nelson Racing Engines LulzBot hardware is made in the USA using domestic and imported parts.

Found in Robotics News & Content, with a score of 43.70

…and performance requirements in the aerospace sector. ASTM International’s additive manufacturing technologies committee (F42) is currently developing the four standards. “The industry uses standards to ensure that public safety, quality, and readiness levels are maintained,” said Shane Collins, general manager at Additive Industries North America and an ASTM member. “Once approved, these standards could be used to certify that parts are manufactured to the highest quality levels required by the U.S. Federal Aviation Administration [FAA] through the part and process qualification procedures.” According to Collins, the new standards could help civil, commercial, and military aircraft manufacturers, as well as producers…

Found in Robotics News & Content, with a score of 35.62

…Technologies will introduce a new benchmark for the FIT Additive Manufacturing Group. Coming online in September 2019 in FIT’s main facility in Lupburg, Germany, the press will enable the additive manufacturing (AM) specialist to boost productivity while responding to the industrial requirements for 3D printed metal series parts. Operating at a temperature of 1400°C (2552°F) and pressure of 30,000 psi (2,070 bar), the press model QIH 32 M URQ offers a capacity of 120 kg (264 lbs.) per load in a work zone that measures 270 mm (10.6 in.) in diameter and 500 mm (19.7) in. in height. Its URQ…

Found in Robotics News & Content, with a score of 12.08

…the annual AeroDef Conference, produced by the Society of Manufacturing Engineers (SME). “I'm a competitor. I look out in the audience and I see my competitors, suppliers, and customers,” said Kevin Smith, sector VP of Global Operations, Northrop Grumman Aerospace Systems, as he began his keynote talk. “But there are a couple of things I won't compete on .. [ That's ] any type of safety products. [If there's] something I can do to help my industry friends be successful in the area of safety, I don't want to compete in that area. I'd share my capability and collaborate with…

Found in Robotics News & Content, with a score of 20.63

…defense suppliers, contractors, and manufacturers gather for the AeroDef Manufacturing Conference (April 29-May 1), produced by the Society for Manufacturing Engineers (SME). A growing area of interest for the attendees is the deployment of digital twins—not just for objects, such as jet engines and helicopters, but also for entire factories, plants, and processes. Exhibitors such as JR Automation and Siemens highlight the technologies available for digital twins in their booths. Also at the show are Creaform, which develops 3D scanning devices; and 3D Systems, an additive manufacturing (AM) system developer. Attendees and featured panelists discuss the concerns for cyberphysical security,…

Found in Robotics News & Content, with a score of 23.78

At the Additive Manufacturing Users Group (AMUG) conference in Chicago last month, a lunchtime conversation summed up the state of additive manufacturing/3D printing technology, and many other technologies. A large supplier to the aerospace industry was voicing a minor complaint about his company’s 3D printers to a representative from a competing 3D printer company. That representative, as you might expect, said his company’s 3D printers did not suffer from that particular malady. “Where were you five years ago when we did all this?” asked the aerospace supplier. “We weren’t a company yet,” replied the 3D printer manufacturer. It was a…

Found in Robotics News & Content, with a score of 26.31

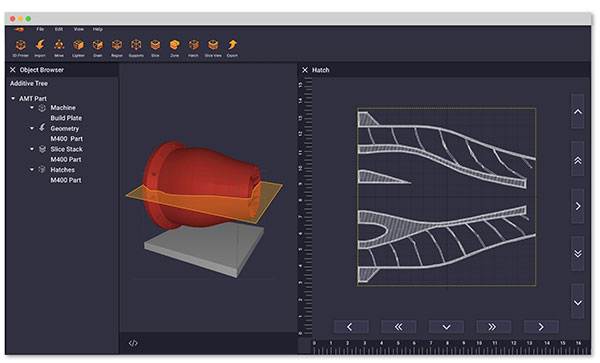

…(g-forces) and pressure. The software also allows design for additive manufacturing and investment casting as a beta release. CogniCAD 2.1’s functional design capabilities include stress, compliance (stiffness) and deformation constraints. The platform enables taking an optimal design and finding its ideal model orientation for additive manufacturing, by minimization of unsupported areas or supports volume, while highlighting areas which require reinforcement. CogniCAD 2.1 introduces 2x calculation speedup and allows users to select the desired combination between resolution and speed of calculations. Finally, there is an enhanced design cabinet view and any minimal glitches in the system have been smoothed out. The…

Found in Robotics News & Content, with a score of 44.20

The National Center for Defense Manufacturing and Machining (NCDMM), parent organization of America Makes, has entered into a formal collaboration agreement with Digital Engineering, to advance the additive manufacturing/3D printing industry. America Makes and its membership community of more than 220 organizations share a common goal to accelerate additive manufacturing and 3D printing to increase the U.S. global manufacturing competitiveness. Digital Engineering will help leverage its magazine, e-newsletters, DigitalEngineering247.com website and marketing database to drive awareness of America Makes’ mission as national accelerator for additive manufacturing and 3D printing. “Digital Engineering (formerly Desktop Engineering) has been covering additive manufacturing and…

Found in Robotics News & Content, with a score of 22.01

3Diligent has now qualified and networked digital manufacturing facilities on six continents. Its network of nearly 250 contract manufacturing partners spans more than a dozen countries and 1,200 machines. This milestone means 3Diligent says it can now offer faster, more cost effective support to customers seeking a single partner for their global custom part manufacturing needs. Through its dynamic use of regional manufacturing facilities near the final delivery address, 3Diligent can cut down on delivery time and shipping costs. 3Diligent can also provide a single platform to track and manage digital manufacturing activity across the enterprise. “The promise and power…