Editors’ Picks

Found in Robotics News & Content, with a score of 22.80

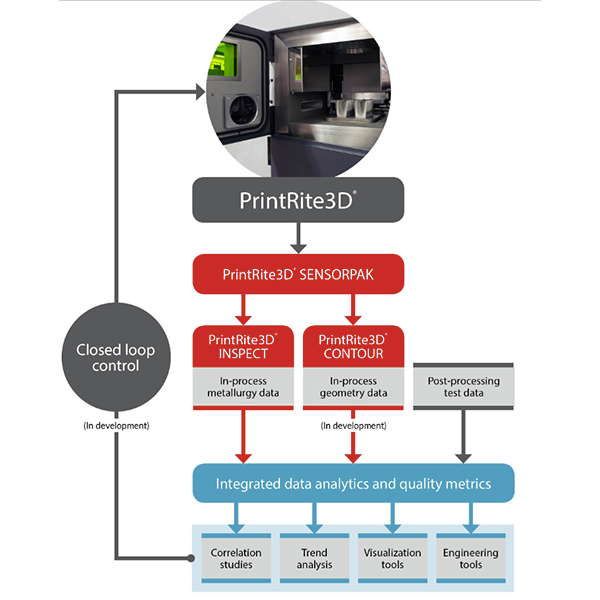

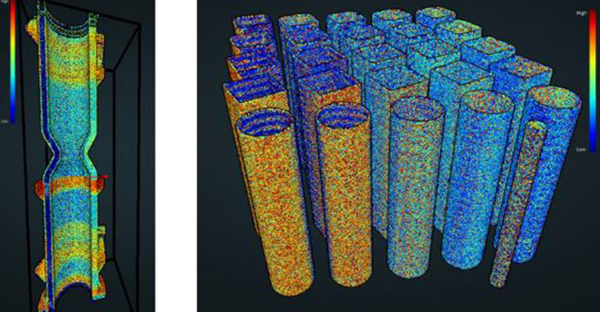

…inspection, feedback, data collection and critical analysis for metal additive manufacturing. The product is being introduced at the RAPID+TCT Additive Manufacturing Conference in Detroit, May 20-23, 2019. The system pairs PrintRite3D SENSORPAK multi-sensors and hardware with PrintRite3D INSPECT, PrintRite3D CONTOUR and PrintRite3D ANALYTICS software modules for comprehensive management of AM processes. Companies using metal additive manufacturing (AM) have traditionally been hindered by the inability to analyze the structure of a part during the manufacturing process. They also lacked the ability to make real-time adjustments to ensure an acceptable level of quality. Sigma Labs says PrintRite3D Version 5.0 resolves these challenges…

Found in Robotics News & Content, with a score of 30.29

Dear DE Reader: Additive manufacturing (AM) has turned a corner. The long-sought goal of printing production parts in volume is becoming a reality. For metal AM specifically, the inability to analyze part structure during the manufacturing process has been a key factor limiting mainstream adoption. Thanks to a significant update, Sigma Labs now offers an independent solution for real-time structure analysis during metal AM part production; it’s why PrintRite3D Version 5.0 is our Editor’s Pick of the Week. PrintRite3D is an in-process quality control platform for metal additive manufacturing. It combines inspection, feedback, data collection and critical analysis. The platform…

Found in Robotics News & Content, with a score of 13.74

…leaders in aerospace and high-performance sports to transform their manufacturing processes through 3D printing. American Magic is a great example of innovative manufacturing leaders pushing the boundaries of success with 3D printing.” American Magic joins a group of Stratasys customers capitalizing on additive manufacturing to advance competitiveness in high performance environments—including auto sports, motor cross and professional winter games. The company says carbon fiber material is suited to align with the requirements of complex, demanding racing—as teams capitalize on 3D printing to accelerate design iterations, workflows and final part production. “The America’s Cup is a racing event like none other…

Found in Robotics News & Content, with a score of 30.45

…As a strategic partner, Indo-MIM will become a full-service manufacturing partner for Desktop Metal, providing companies looking for a wide range of mass production with quantities of high-quality metal parts, ranging from tens of thousands to 1 million. Indo-MIM will also offer customers consulting services around downstream manufacturing and finishing processes key to going to production with metal additive manufacturing. “This is a major step forward in the progress of additive manufacturing,” says Krishna Chivukula, Jr., CEO of Indo-MIM. “We are excited to partner with Desktop Metal to bring metal additive manufacturing closer to those companies looking to achieve the…

Found in Robotics News & Content, with a score of 25.39

…importance of automated post-processing for industrial applications of 3D printing/additive manufacturing. The 3D printed production process chain often consists of a series of unconnected digital manufacturing processes, which require manual intervention that can slow down production rates and add costs. Folgar will highlight how AMT’s BLAST process intersects material science, hardware engineering and process automation as a solution to these challenges. The BLAST process is at the heart of the PostPro3D portfolio of hardware that AMT says offers performance and aesthetic enhancement for 3D-printed parts for mass production applications. Folgar will also introduce the PostPro3DColor and PostPro3DMini systems, which visitors…

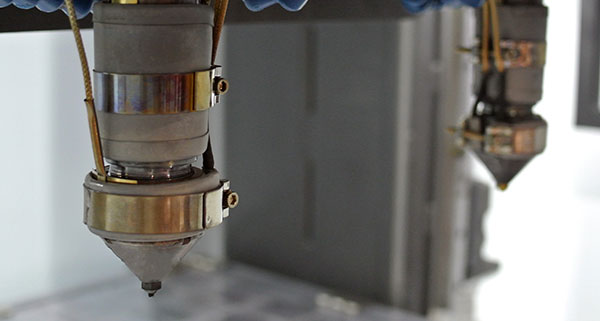

Found in Robotics News & Content, with a score of 42.95

…directed energy deposition (DED) systems, will demonstrate simultaneous five-axis additive manufacturing at its At RAPID+TCT 2019 booth (#517). The technology is said to enable new capabilities for building, repairing and coating mid- to large-size complex metal parts. The new Optomec LENS additive plugin is toolpath generation software that enables simultaneous five-axis control. When combined with the Siemens Sinumerik 840D CNC, complex geometries can be printed faster and easier, according to Optomec. “Optomec has once again pushed DED printing capability to new heights,” said Tim Bell, additive manufacturing industry manager at Siemens in a press release. “By leveraging the outstanding system…

Found in Robotics News & Content, with a score of 19.81

…on PA6-carbon fiber composites extend Impossible Objects’ composite based additive manufacturing process (CBAM) to a range of industrial applications. “It’s been exciting to see how our customers are putting our approach to work to create high-performance parts for everything from aircraft and cars to lightweight athletic gear,” says Impossible Objects founder and chairman Bob Swartz. “We’re continuing to bring machines, materials and expertise to the market to transform the entire manufacturing process, from prototyping through to high-volume production.” CBAM-2 Speeds Production of 3D Parts at Scale The new CBAM-2 3D printing system, being shown at RAPID + TCT for the…

Found in Robotics News & Content, with a score of 23.92

…development and implementation of pellet extrusion technology in the additive manufacturing industry,” says Clay Guillory, Titan Robotics CEO, via a press release. “Our Atlas-H product launch aligns with Titan’s mission to develop innovative solutions and technologies to bring additive manufacturing into industrial production.It strengthens Titan’s reputation as one of the most innovative companies in the industry.” Titan has been a pioneer in the development and implementation of pellet extrusion technology in the additive manufacturing industry. Image courtesy of Titan Robotics. Titan Robotics says pellet extrusion 3D printing on the Atlas with a heated enclosure significantly increases the number of materials…

Found in Robotics News & Content, with a score of 23.11

Adding a new page to its high-performance, additive manufacturing playbook, Stratasys today inked an agreement with Arrow Schmidt Peterson Motorsports, which competes in the NTT IndyCar Series. The team is leveraging Stratasys’ Fortus 450mc 3D Printer—capable of printing carbon fiber-reinforced FDM Nylon 12—and F370 3D Printer as part of its manufacturing process. The Fortus 450mc 3D Printer offers FDM Nylon 12 Carbon Fiber and ASA materials. This technology is aimed at creating functional prototypes, product components, and rugged tooling that match demands for strength and stiffness of carbon-filled composite material. “Competitive racing is the ideal test track to demonstrate the…

Found in Robotics News & Content, with a score of 12.19

…center of a volume printing solution for production 3D manufacturing. The printing system counts BASF, Materialise and Siemens as strategic partners, creating what HP calls “a new global community of proven large-scale 3D printed parts providers.” The printer is the latest refinement of HP’s work in Multi Jet Fusion (MJF) printing technology, which prints on a line-by-line basis. HP says the method is inspired by its long history of 2D wide format printing, but relies on a variety of innovations for 3D. HP says MJF allows for faster cooling and increased automation of post-processing compared to selective laser sintering (SLS).…

Found in Robotics News & Content, with a score of 22.11

Sintavia, LLC, has officially opened the new 55,000-square-foot advanced manufacturing facility, located in Hollywood, FL. The new plant, which also serves as the company’s headquarters, celebrated its grand opening on May 9 at an event with over 150 customers, industry partners and government officials. “This new facility is the first of its kind in North America to offer large-scale AM production coupled with a robust aerospace quality management system,” says Brian Neff, Sintavia’s chairman and chief executive officer. “As we grow, it will serve as a template for future vertically-aligned advanced manufacturing facilities around the U.S. and the world.” Sintavia’s…

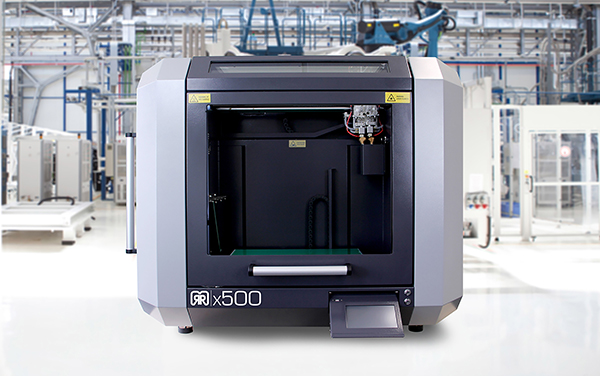

Found in Robotics News & Content, with a score of 44.69

In the automotive industry, additive manufacturing has become a high priority, according to German RepRap. Different car parts and prototypes are developed with the help of additive manufacturing and thus a faster achievement of the series maturity is possible. In prototyping, fixtures, production and assembly aids, the technology has become the standard and allows the use in end products through the use of various flexible materials. German RepRap has been supplying the BMW Group for several years. The German RepRap x500 is used, for example, for the production of prototypes in the field of predevelopment. One of the most decisive…