Editors’ Picks

Found in Robotics News & Content, with a score of 43.42

Evonik Corporation and Evolve Additive Solutions, Inc. have announced a joint development agreement where the companies will work together to formulate Evonik’s thermoplastic materials to be used in Evolve's selective thermoplastic electrophotographic process (STEP) additive manufacturing solutions. The initial development efforts will focus on polyamide 12, PEBA, transparent polyamide, and polymer of the polyamide 6 series. Evolve’s STEP technology will operate alongside traditional manufacturing processes, such as injection molding on the manufacturing floor, augmenting an organization’s production capabilities and allowing freedom of design and faster time to market with “toolless” production. The selective thermoplastic electrophotographic process from Evolve is still…

Found in Robotics News & Content, with a score of 15.46

…in latter May 2019 at the RAPID + TCT Additive Manufacturing Conference in Detroit, and will ship to first customers later this year. Markforged says Blacksmith “makes manufacturing machines ‘aware’ so they can automatically adjust programming to ensure every part is produced as designed.” The initial release of Blacksmith will work with selected Markforged metal 3D printers. The long-term goal is for Blacksmith to be compatible with all manufacturing machines, not just 3D printers. Starting with Markforged’s Metal X and X7 3D printers, Blacksmith will create a continuous feedback loop to make 3D printed parts more accurate. Markforged says the…

Found in Robotics News & Content, with a score of 12.47

…printing into all avenues of its product development and manufacturing processes, Ford is pursuing a pilot project to jump-start the design of tools and fixtures, including making it easier for plant floor workers to produce components on their own without help from experienced experts. Ford’s Cologne, Germany, pilot plant maintains a small-scale manufacturing line, which develops cars years before they go into production. As part of their efforts, the team has been honing an optimized workflow to create jigs, tools and fixtures at local plants using 3D printing techniques as opposed to subbing out the components to external partners. Ford…

Found in Robotics News & Content, with a score of 16.55

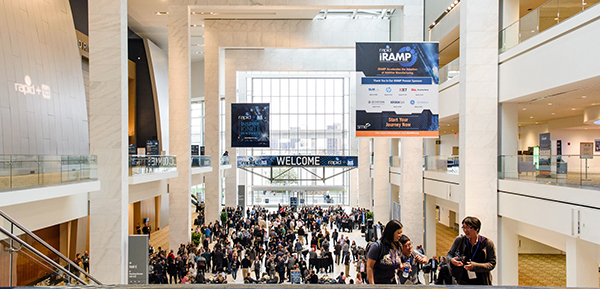

…and 400-plus exhibitors had access to more than 100 additive sessions in the Motor City of Detroit, home to GM, Ford and Chrysler. Though autonomous vehicle technology and 3D printing’s role in automotive surfaced as relevant topics at the show, the auto sector was just one focal point among many on the 3D printing landscape being discussed at the event. Joe Louis, famed boxer, greets guests upon entering the Cobo Center for the RAPID+TCT 2019 annual conference. “This event is an annual celebration of additive manufacturing and the achievement and dedication of this community,” 2019 SME President Mark Michalski said…

Found in Robotics News & Content, with a score of 38.69

Jabil has announced an additive manufacturing agreement with Renault F1 Team to speed the development and delivery of 3D-printed racecar parts for the Renault R.S.19, competing in the 2019 Formula One World Championship. Through the Jabil Additive Manufacturing Network, Renault F1 Team will gain fast and efficient access to top-quality parts. “We’re excited to be part of Renault F1 Team’s strategy to improve performance with additive manufacturing,” said John Dulchinos, VP of digital manufacturing, Jabil. “Our ability to consolidate a global supply chain and scale qualified processes as needed will enable the production of chassis and on-car components in record…

Found in Robotics News & Content, with a score of 31.25

…the cutting edge of binder jetting technology adoption for additive manufacturing. “We see binder jetting technology as a key enabler for our differentiated, high-performance wear materials, such as tungsten carbide and Kennametal Stellite alloys,” said Sherri McCleary, director, Business Development Additive, Kennametal. “Kennametal is uniquely qualified to supply these additive materials and components, and we’re pleased to collaborate with ExOne on cutting-edge technology with the potential to help us advance from prototyping to serial production.” The new X1 25PRO was revealed at the RAPID + TCT this week. The high-resolution production machine is capable of printing metal, ceramic and other…

Found in Robotics News & Content, with a score of 18.86

…(SLA) and selective laser sintering (SLS) 3D printers for manufacturing. The industries it servers span everything from aerospace, architecture, art and automotive to consumer goods, eyewear, healthcare, machinery and service bureaus/contract manufacturers. In Plymouth, the focus is on medical production and sales/marketing for Materialise software for additive manufacturing and medical applications. On this night, the focus was “3D in the D,” accentuated by the “Built in Detroit” theme underpinning the evening’s highlights. Upon entering the 45,000-sq.-ft. building, we were greeted by Materialise leadership and staff, and received a 3D-printed puzzle base to save for the tour, during which we'd collect…

Found in Robotics News & Content, with a score of 32.52

…a global science-based company has partnered with Adaptive3D, an additive manufacturing polymer resin supplier, to help produce, distribute and sell Adaptive3D’s newest product, Soft ToughRubber, a new 3D printable photopolymer. The new material allows manufacturers to explore applications in medical models and consumer products such as audio earbuds and footwear. The partnership will guarantee the availability of the new material in production volumes worldwide, according to the company. DSM invested in Adaptive3D Technologies earlier in 2019, and now partners with the company to sell, distribute and produce Soft ToughRubber, Adaptive3D’s new material. The material is said to combine the feel…

Found in Robotics News & Content, with a score of 23.84

…says is critical to protect electrostatic-sensitive devices in electronics manufacturing, oil and gas and aerospace industries. Essentium says the HSE 3D printer is up to 10x faster and 5x more accurate than competitive offerings. The 3D printing platform offers print speeds greater than 500mm a second by using a non-slip, high torque extruder system and all linear motor. Supplementing the capabilities of the hardware, Essentium says it has tuned the materials accordingly to process at speed while being strong enough to withstand impact loading, fatigue or cyclic loading and protect electrostatic-sensitive devices. The company says early access program customers are…

Found in Robotics News & Content, with a score of 15.61

…and Essentium to bring improved productivity and connectivity to additive manufacturing operations. Materialise also announced that it will release a new version of its 3D printing operations management software, Streamics 8 in June 2019, and the availability of Materialise Simulation 2.0 as an optional module with Materialise Magics 23. HP and Materialise Collaborate on Industrial-Scale 3D printing Materialise has expanded its collaboration with HP, developing a new version of its build processor to support the full range of printers in the HP Multi Jet Fusion portfolio, including the Jet Fusion 5200 and Jet Fusion 500/300 Series of 3D printing solutions.…

Found in Robotics News & Content, with a score of 24.88

…AM-ready materials for the most demanding applications in a large number of industries,” said Christophe Schramm, business manager for Additive Manufacturing in Solvay’s Specialty Polymers Global Business Unit. “This is fully in line with Solvay’s ambition to push the limits of high-performance additive manufacturing.” Solvay Specialty Polymers manufactures over 1,500 products across 35 brands of high-performance polymers. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 9.30

…delivery, and centralized post-processing, manufacturers can reduce demand on manufacturing resources and lower total cost of operation, according to the company. Additionally, it is 3D Connect-capable, allowing remote services via 3D Connect Service that automatically notifies 3D Systems’ service team when an alert condition occurs. Figure 4 Modular is planned for general availability in June 2019. Figure 4 Production is a customizable and automated tool-less manufacturing solution that packages the design flexibility of additive manufacturing in configurable, in-line production modules. Automated material delivery and integrated post-processing are intended to reduce labor requirements, increase productivity and lower total cost of operation.…