Editors’ Picks

Found in Robotics News & Content, with a score of 29.05

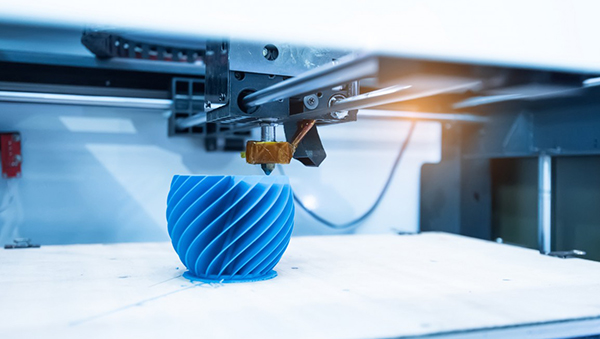

…Stratasys have announced the winners of their co-sponsored 2019 Additive Manufacturing Competition, held during the 55th annual SkillsUSA National Leadership and Skills Conference in Louisville, KY, in late June. Six teams—three high school and three college teams—received top honors for the designs they created during the three-day contest. SME and Stratasys have collaborated on the contest for the past 5 years, designing the challenge to educate high school and postsecondary students about additive manufacturing technologies while providing them with real-world, hands-on experience using the technology. “Every year the participants in our SkillsUSA Additive Manufacturing Competition impress us with how much…

Found in Robotics News & Content, with a score of 34.06

…software suite. For companies entering into or scaling their additive manufacturing, 3YOURMIND software helps identify AM suitable parts from existing inventories. For companies and 3D printing services who are already actively 3D printing, the software suite becomes their digital access point for accurate pricing, file management, automated order processing and transparent tracking of the production floor. In 2019, in addition to building out machine connectivity, 3YOURMIND will focus on interlinking their software suite with machine learning to improve depth of optimization, lower processing costs and move additive manufacturing towards automated production streams. This is 3YOURMIND’s vision for Agile Manufacturing. More…

Found in Robotics News & Content, with a score of 30.26

A new reinforcement of Weerg's additive manufacturing department announces the installation of the ProX SLS 6100 printer by 3D Systems. Based on selective laser sintering (SLS) technology, this system can handle rapid production of functional and durable nylon parts. The implementation of ProX SLS 6100 allows Weerg to offer new features and finishes for components made of SLS, thanks to the use of white DuraForm materials supplied by 3D Systems that could be colored with the Girbau systems already installed, expanding the range of shades that the customer can select when ordering. “We were looking for a solution that would…

Found in Robotics News & Content, with a score of 40.94

The software specialist CoreTechnologie (CT) has developed the 4D_Additive Manufacturing Software Suite. A particular highlight of the new software is the texture module. With the new texture module of 4D_Additive Manufacturing Software, developers and industrial designers are now accessing over 5,000 different surface structures. The combination of the software with B-Rep kernel and the high-resolution HP Jet-Fusion process allows the additive production of very fine, completely new surfaces, which can have use for individualized decorative trim in vehicles and plastic design products, according to the company. For users, 4D_Additive makes it easy to define textures on the CAD model, simply…

Found in Robotics News & Content, with a score of 11.12

…Altair. With Autodesk Fusion, you can specify the preferred manufacturing method so the software can take it into consideration when it generates the topology. For more on this, read our online report on the VW Type 20 at Digital Engineering 247.com. The wheel of the new VW Type 20 concept van, designed with Autodesk Fusion's generative design. Image courtesy of Volkswagen Group. RoboCup brings out advanced autonomous technology Perhaps some of you are soccer fans, or football, as it’s known in other parts of the world, but do you know there’s a robotic football cup? It's called RoboCup, and the…

Found in Robotics News & Content, with a score of 14.47

…and product development company specializing in artificial intelligence, digital manufacturing, 3D printing, robotics and the digital transformation of traditional businesses, announced the expansion of its Ventura-based Innovation Labs and the opening of a new manufacturing facility that will see its floor space double. The expansion reflects the rapid growth and expansion of XponentialWorks’ portfolio companies as each company is commercializing their products and services. XponentialWorks expects that this expansion will create dozens of new high-tech and Manufacturing 4.0 jobs, and enhance the innovation and manufacturing infrastructure for the benefit of its portfolio companies, including NXT Factory, Nexa3D and Apollo Robotics,…

Found in Robotics News & Content, with a score of 23.97

…3D printer. 3D Systems and the National Center for Manufacturing Sciences (NCMS) were awarded funding to create this revolutionary printer and will partner with ARL and the Advanced Manufacturing, Materials, and Processes (AMMP) Program to advance the leadership and innovation of the world’s strongest military. According to the U.S. Army Additive Manufacturing Implementation Plan, the Army has been using additive manufacturing (AM) for two decades to refurbish worn parts and create custom tools. Once developed, the Army will leverage its manufacturing experience by placing the new large-scale systems in its depots and labs. Subsequently, 3D Systems and its partners plan…

Found in Robotics News & Content, with a score of 28.32

Nano Dimension Ltd. has sold its DragonFly Pro additive manufacturing system for electronics to Istituto Italiano di Technologia (IIT) Biomolecular Nanotechnologies. IIT is a research institution in Italy specializing in promoting technological development and higher education in science and technology. The IIT staff is comprised of approximately 1,700 people from over 60 countries, working together to conduct research in multidisciplinary areas such as robotics, nanobiotechnology, industry, computational science and medicine. The research at the IIT Center for Biomolecular Nanotechnologies in Lecce is focused on the development of micro and nanotechnologies for the human body and for the environment, by studying…

Found in Robotics News & Content, with a score of 11.62

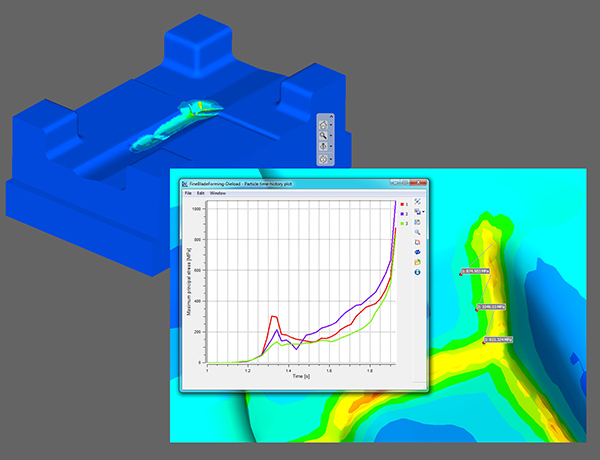

…a simulation and analysis software suite for modeling complex manufacturing machines and forming processes. Rewritten throughout for increased efficiency and ease of use, Forming Version 16 also offers various new features and enhancements for building robust simulation models. The new geometry data check feature allows users to identify simulation error as well as check their position within the geometry. This new model data can be sent back to the CAD model, allowing retracing of corrections. The user then reimports the optimized tool geometry and continues setting up the model. Simulation of a carrier in MSC Simufact Forming Version 16. Image…

Found in Robotics News & Content, with a score of 40.74

…company Huntsman outlined details of a new range of additive manufacturing materials that it has developed. Huntsman’s IROPRINT additive manufacturing platform contains three kinds of urethane-based materials (resins, powders and filaments), which can be 3D printed using various additive manufacturing methods including stereolithography (SLA), high speed sintering (HSS) and fused filament fabrication (FFF). Initially, Huntsman is launching its range of soft, flexible IROPRINT additive manufacturing materials in the global footwear and sports industry, where 3D printing is being used to make both customized and mass manufactured shoes. Longer term, Huntsman plans to roll its IROPRINT additive manufacturing platform out across…

Found in Robotics News & Content, with a score of 39.94

Renishaw has supplied four RenAM 500Q metal additive manufacturing machines to Knust-Godwin, a precision machining company located in Katy, TX. The high-productivity machine, designed for serialized industrial manufacturing, helps Knust-Godwin to reduce lead times for its customers. Knust-Godwin has history of machining large, complex parts for oilfield instrumentation. The company first introduced additive manufacturing as a new technology to help improve the efficiency and productivity of tools in the oil and gas industry. The company chose to expand its additive manufacturing (AM) capacity to handle serial production, purchasing four RenAM 500Q machines. “Additive manufacturing started as a prototyping technology, but…

Found in Robotics News & Content, with a score of 25.52

…aircraft performance. With VELO3D, Boom hopes to use metal additive manufacturing to accelerate aircraft development and improve system performance. “High-speed air travel relies on technology that is proven to be safe, reliable, and efficient, and by partnering with VELO3D we’re aligning ourselves with a leader in additive manufacturing that will print the flight hardware for XB-1,” says Mike Jagemann, head of XB-1 Production, Boom Supersonic. “VELO3D helped us understand the capabilities and limitations of metal additive manufacturing and the positive impact it would potentially have on our supersonic aircraft. We look forward to sharing details about the aircraft development and…