Editors’ Picks

Found in Robotics News & Content, with a score of 13.25

…Cloud Light’s proven capabilities in optical module design, high-volume precision assembly, testing, and reliability engineering complement and complete SiLC’s manufacturing ecosystem, which includes its proprietary chip-fabrication process with another major ecosystem partner in Asia. Early sample shipments and the transition to volume production are expected this year. “To integrate all of the functionalities needed for a coherent lidar into a single photonic chip is a complex art that takes many years to master,” said Dr. Mehdi Asghari, SiLC’s CEO and founder. “The combination of precision optical assembly and automotive capabilities make Cloud Light an ideal partner for manufacturing our vision…

Found in Robotics News & Content, with a score of 12.31

…global designer, manufacturer, and distributor of farming machinery and precision agriculture technology. Its portfolio includes brands like Challenger, Fendt, GSI, Massey Ferguson, Precision Planting, and Valtra. Powered by Fuse smart farming systems, AGCO said its full line of equipment and services help farmers sustainably feed our world. The Duluth, Ga.-based company had net sales of approximately $11.1 billion in 2021. AGCO developed the Fendt Xaver award-winning autonomous robot concept as part of a research project. Fendt Xaver uses 90% less energy than conventional machines because of its lightweight electric design, which produces zero emissions, noted the company. AGCO has used…

Found in Robotics News & Content, with a score of 12.17

…uptime and a small footprint. SICK is displaying its high-precision robot guidance system for localizing items to be picked. A high-resolution, high-speed camera detects a wide range of objects of different shapes and colors. The robot has automatic detection of all kinds of objects, even in challenging applications with reflective and shiny objects. It can localize items in multiple bins and has a highly accurate picking rate due to a high-precision 3D point cloud. In addition, the robot includes artificial intelligence and machine learning so it can be trained for new scenarios using dStudio from SICK and the classification of…

Found in Robotics News & Content, with a score of 7.86

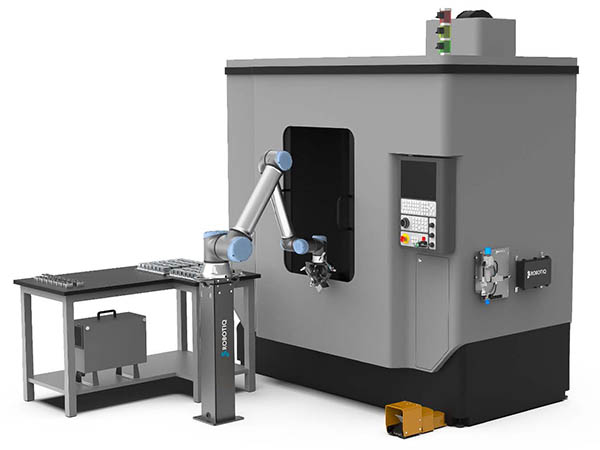

…at Usinatech Inc. His company, in Melbourne, Quebec, does high-precision machining for drive-train and transmission components such as gears and shafts. “I never thought a robot would replace me, and I am happy to have my three robots,” said Hugo Santos, an operator at Usinatech. “My speed keeps increasing.” “Running a job on a given machine with UR and Robotiq is four times cheaper than operating manually,” noted Ken Chess, chief operating officer at Fusion OEM. Robotiq is showing its Machine Tending Application Solution at Booth 2438 at the Automate trade show in Detroit from June 6 to 9, 2022.

Found in Robotics News & Content, with a score of 7.40

…is surging.” “TM Robot with built-in vision has offered precision and flexibility through the automation of food preparation,” it added. “Besides, it provides human safety and food hygiene safety at the same time. Several well-known companies have implemented TM Robots. From food to electronics manufacturing, it can be applied in a wide range of industries.” TM Robot updates safety, ease of use Techman Robot noted that the TM Robot S includes both software and hardware upgrades to quickly assist customers in creating collaborative robot applications. The company said it has completely revised its TMFlow human-machine interface. Version 2.0 provides a…

Found in Robotics News & Content, with a score of 7.88

…“As the demand for automation continues across all industries, Epson pushes the envelope by providing high-performance solutions with leading-edge precision to meet the most demanding tasks,” said Scott Marsic, group product manager at Epson Robots in a statement. “With the new GX Series, the GX4 and GX8 SCARA robots allow users to manage robotic solutions powerfully and with a compact footprint. Integration with Epson RC+ software helps manufacturers get the most out of their robots in terms of simplicity and performance.”

Found in Robotics News & Content, with a score of 7.36

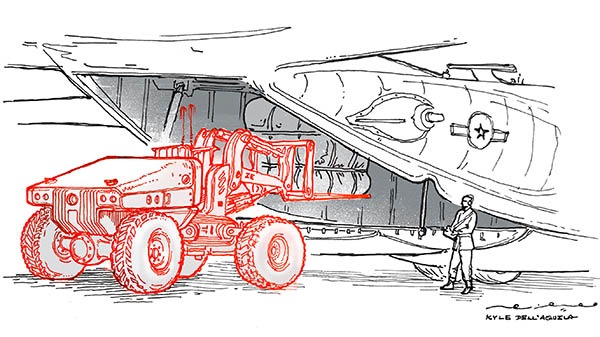

…The company said it addresses the battery-electrification problems inherent in hydraulic systems by delivering hydraulic-like forces at unprecedented efficiency, precision, speed, and weight. RISE Cylinder uses up to 90% less energy than hydraulic cylinders. RISE Robotics said it is leading the way to environmentally sustainable heavy machinery by providing the world’s most efficient and productive alternative to hydraulics. Designed for medium- and heavy-duty applications, RISE said its technology can provide fuel, emissions, and sound reductions; improve productivity; and extend machine life.

Found in Robotics News & Content, with a score of 7.09

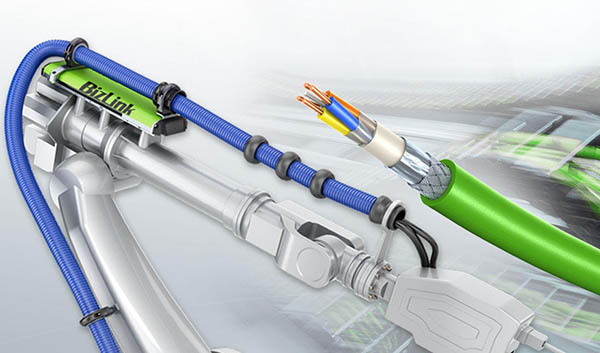

…safely and effectively. BizLink offers custom technical training for a company’s individual needs. Tool calibration systems: Automation systems require precision. BizLink’s advintec TCP tool calibration system helps calibrate robotic tools and fixtures in up to six dimensions. “Like everyone else in our rapidly evolving space, we very much look forward to returning to Automate this year to share our excitement about our new company and our solutions and to discuss how we can help companies solve their most challenging industrial automation problems,” said Vico.

Found in Robotics News & Content, with a score of 7.03

…printer, to print and apply product, warning, and shipping labels from a single printer. Offering label placement flexibility and precision for packaging, Epson's ColorWorks printers are ideal for part identification, visual management and displaying product pictures on packaging. Epson Robots will be at Booth 2018.

Found in Robotics News & Content, with a score of 9.59

…procedures for improving a robot's accuracy. Robot calibration requires precision laser systems to calibrate the robotic mechanism itself. Tool center point (TCP) calibration is a simpler procedure to ensure the programming system has an accurate model of the robot's tool. The typical way of calibrating a robot tool center point (TCP) is by a four-point method, which consist of taking a series of at least for four joint readings when moving the tool to the same point with different orientations. This process is time consuming and less accurate as the user needs to move the robot in different position manually.…

Found in Robotics News & Content, with a score of 4.38

…meters to less than 10 microns with the highest precision and maximum efficiency, based on Gecomer Technology. Inspired by the so-called Gecko effect, picking and placing of the component works without external energy and without any residues – by using van der Waals interactions. InOrbit Inc. (Mountain View, Calif.; Booth 4355), the leading provider of software-as-a-service (SaaS) robot operations, or RobOps—DevOps for robotics. InOrbit offers a secure, scalable, cloud-based robot management and analytics platform that enables robotics companies and their customers to develop, deploy and operate smart robots at global scale. Its platform is designed to seamlessly integrate with your…

Found in Robotics News & Content, with a score of 7.36

…them smaller.” Feedback devices have also improved in size, precision, and quality. “With higher-resolution encoders, we not only see better accuracies, but tuning can also be improved to help with accuracy and cycle time when applied to the applications,” said Dieck. “This opens the door for higher-precision robotics applications, and it improves repeatability and the throughput of the robot and automation.” Furthermore, smaller motors with better torque-to-weight ratios allow motors to achieve high peak speeds for a short time, as well as faster acceleration and deceleration times. This allows robots to have a reduced mass, which in turn permits more…