Editors’ Picks

Found in Robotics News & Content, with a score of 7.36

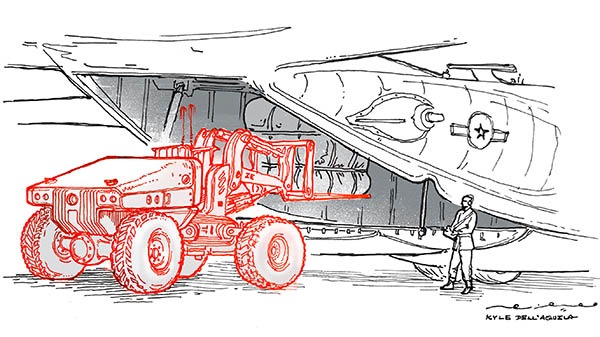

…The company said it addresses the battery-electrification problems inherent in hydraulic systems by delivering hydraulic-like forces at unprecedented efficiency, precision, speed, and weight. RISE Cylinder uses up to 90% less energy than hydraulic cylinders. RISE Robotics said it is leading the way to environmentally sustainable heavy machinery by providing the world’s most efficient and productive alternative to hydraulics. Designed for medium- and heavy-duty applications, RISE said its technology can provide fuel, emissions, and sound reductions; improve productivity; and extend machine life.

Found in Robotics News & Content, with a score of 7.09

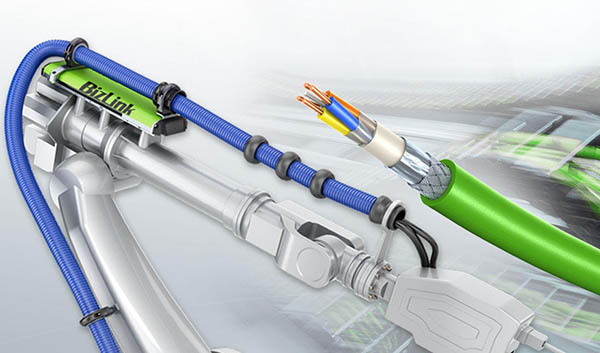

…safely and effectively. BizLink offers custom technical training for a company’s individual needs. Tool calibration systems: Automation systems require precision. BizLink’s advintec TCP tool calibration system helps calibrate robotic tools and fixtures in up to six dimensions. “Like everyone else in our rapidly evolving space, we very much look forward to returning to Automate this year to share our excitement about our new company and our solutions and to discuss how we can help companies solve their most challenging industrial automation problems,” said Vico.

Found in Robotics News & Content, with a score of 7.03

…printer, to print and apply product, warning, and shipping labels from a single printer. Offering label placement flexibility and precision for packaging, Epson's ColorWorks printers are ideal for part identification, visual management and displaying product pictures on packaging. Epson Robots will be at Booth 2018.

Found in Robotics News & Content, with a score of 9.59

…procedures for improving a robot's accuracy. Robot calibration requires precision laser systems to calibrate the robotic mechanism itself. Tool center point (TCP) calibration is a simpler procedure to ensure the programming system has an accurate model of the robot's tool. The typical way of calibrating a robot tool center point (TCP) is by a four-point method, which consist of taking a series of at least for four joint readings when moving the tool to the same point with different orientations. This process is time consuming and less accurate as the user needs to move the robot in different position manually.…

Found in Robotics News & Content, with a score of 4.38

…meters to less than 10 microns with the highest precision and maximum efficiency, based on Gecomer Technology. Inspired by the so-called Gecko effect, picking and placing of the component works without external energy and without any residues – by using van der Waals interactions. InOrbit Inc. (Mountain View, Calif.; Booth 4355), the leading provider of software-as-a-service (SaaS) robot operations, or RobOps—DevOps for robotics. InOrbit offers a secure, scalable, cloud-based robot management and analytics platform that enables robotics companies and their customers to develop, deploy and operate smart robots at global scale. Its platform is designed to seamlessly integrate with your…

Found in Robotics News & Content, with a score of 7.36

…them smaller.” Feedback devices have also improved in size, precision, and quality. “With higher-resolution encoders, we not only see better accuracies, but tuning can also be improved to help with accuracy and cycle time when applied to the applications,” said Dieck. “This opens the door for higher-precision robotics applications, and it improves repeatability and the throughput of the robot and automation.” Furthermore, smaller motors with better torque-to-weight ratios allow motors to achieve high peak speeds for a short time, as well as faster acceleration and deceleration times. This allows robots to have a reduced mass, which in turn permits more…

Found in Robotics News & Content, with a score of 3.60

…in an X/Y table application. FANUC said its new LiS-B series linear motors have set new standards for acceleration, precision and speed, delivering high gain and rigidity with excellent path accuracy. Unlike conventional drives, these motors work without any force transmission mechanisms, making machine design and maintenance easier (no ball screws, no backlash), the company said. The linear design enables rigid long-stroke axes, increased thrust force and multi-head configurations by arranging multiple coil sliders on a single magnet track. The company will also have a Panel I Industrial PC demo.

Found in Robotics News & Content, with a score of 4.39

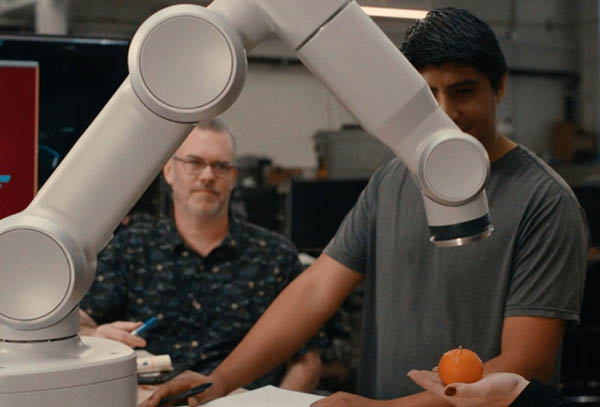

…most difficult tasks that require heavy lifting or minute precision,” said Ally Robotics. “It is nearly impossible for companies struggling in low-margin industries to integrate robotics into their operations – especially for use cases that require robots to work side by side with human beings.” Since many restaurants, fast-casual chains, and fast-food franchises are considering adding automation, keeping the price down will be essential to scaling up, acknowledged Tolson. “Ally Robotics’ robotic arms are built with novel, lower-cost robotic joints and actuators to keep the prices low and are designed to manufacture at scale using these materials from prototype to…

Found in Robotics News & Content, with a score of 6.13

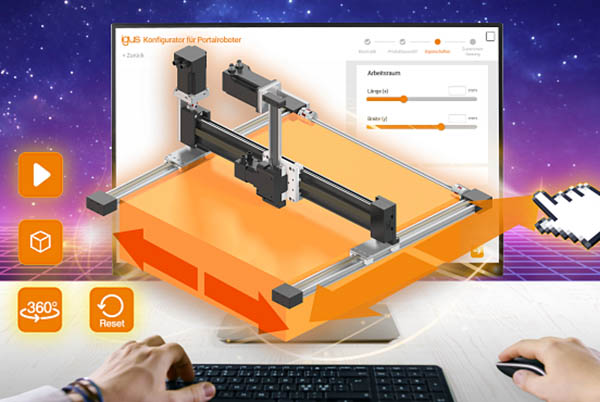

…of the X, Y, and Z axes with millimeter precision. A dynamic 3D model of the linear robot, which can be rotated in all directions, visualizes the settings in real time. “We have added a new function at this point,” said Mühlens. “With one click, it is now possible to also display the installation space of the linear robot. We use colored areas for this. This gives users a visual impression of how much space their automation solution takes up.” To ensure transparency in terms of costs, users also receive an instant display of the price of their automation solution.…

Found in Robotics News & Content, with a score of 3.73

…a way to assess progress with both ease and precision. Is a foundation being set to the correct depth? Is a frame level? Is the project progressing on schedule? All these questions and more can be safely and accurately assessed using quadruped robots. Unassisted AI Delivery Traditional, wheeled, mobile robots are already experiencing a growing wave of commercial adoption, especially as e-commerce delivery systems. Their ability to transport goods through planned, paved roads, and other such structured environments is proving to be incredibly successful. However, when it comes to complex, unpredictable, and unstructured environments, these bots are ill equipped. These…

Found in Robotics News & Content, with a score of 5.21

…and CEO of SiLC. “This and the combination of precision velocity enables a vastly simplified and lower-latency perception stack. We’re pleased to partner with AutoX, a company dedicated to improving the safety and performance of autonomous vehicles.” Eight-channel flash FMCW lidar. Source: SiLC Technologies Muenster explained: “Autonomous vehicles need to perceive objects up to 500 m [1,640.4 ft.] out for safety. With time-of-flight [ToF] and 3D cameras, you need to get pixels at distance to get volume information, which is important for object identification. Cameras are only so good at perceiving objects, and radar is typically blocky or has poor…

Found in Robotics News & Content, with a score of 8.47

…transponders, claimed Humatics. The system is capable of sub-millimeter precision while delivering highly-valuable data regarding the asset's movement including pose, pitch, yaw, speed, etc., the company said. This data can be used to control assets in real time, digitize human movement for robotic interaction for process improvements, and identify manufacturing issues, among other use cases, said Humatics. “The end result of leveraging microlocation is an improvement to productivity, quality, and/or operational efficiency to positively impact profitability,” said Ronald Ranaldi, senior vice president of sales and marketing at Humatics. “With the new transponders, organizations can improve their business to further contribute…