Editors’ Picks

Despite the increased interest in metal additive manufacturing (AM), engineering organizations are struggling to find a definitive formula to make a business case for the technology as a viable method for production. There is no one calculation or cost-benefit analysis that justifies the economics—often, it will come down to a more nebulous equation based on “it depends.” Metal AM, though around for the last couple of decades, has garnered a lot of attention recently as new capabilities and materials innovations advance what the platforms are capable of producing while lower price points put the technology in reach of a wider…

Desktop 3D printers may look like any professional and packaged office unit, but most of the technologies require messy post-processing chemicals and many are associated with particle emissions, all of which present safety risks to operators. In recognition of the problem, UL, a leading safety science company, published a set of emission standards for the 3D printing industry in the hopes of managing the problem and creating a safer environment for usage, particularly in non-industrial environments. The published emissions standard, UL 2904 GREENGUARD, aims to set emissions limits so that 3D printers can be used in office environments, hospitals, and…

There’s plenty of interest in deploying additive manufacturing (AM) technologies for production applications, yet a number of factors, including cost, complexity, and a scarcity of industrial-grade materials, has stymied companies’ efforts to make a serious transition to the new model. The tide is starting to turn thanks to a spate of new industrial-grade AM technologies and more recently, a wave of new advanced material choices that are making it easier and more affordable for companies to 3D print production-grade parts. New high-performance materials tuned to withstand harsh environments and that exhibit properties on par with injection molded parts are giving…

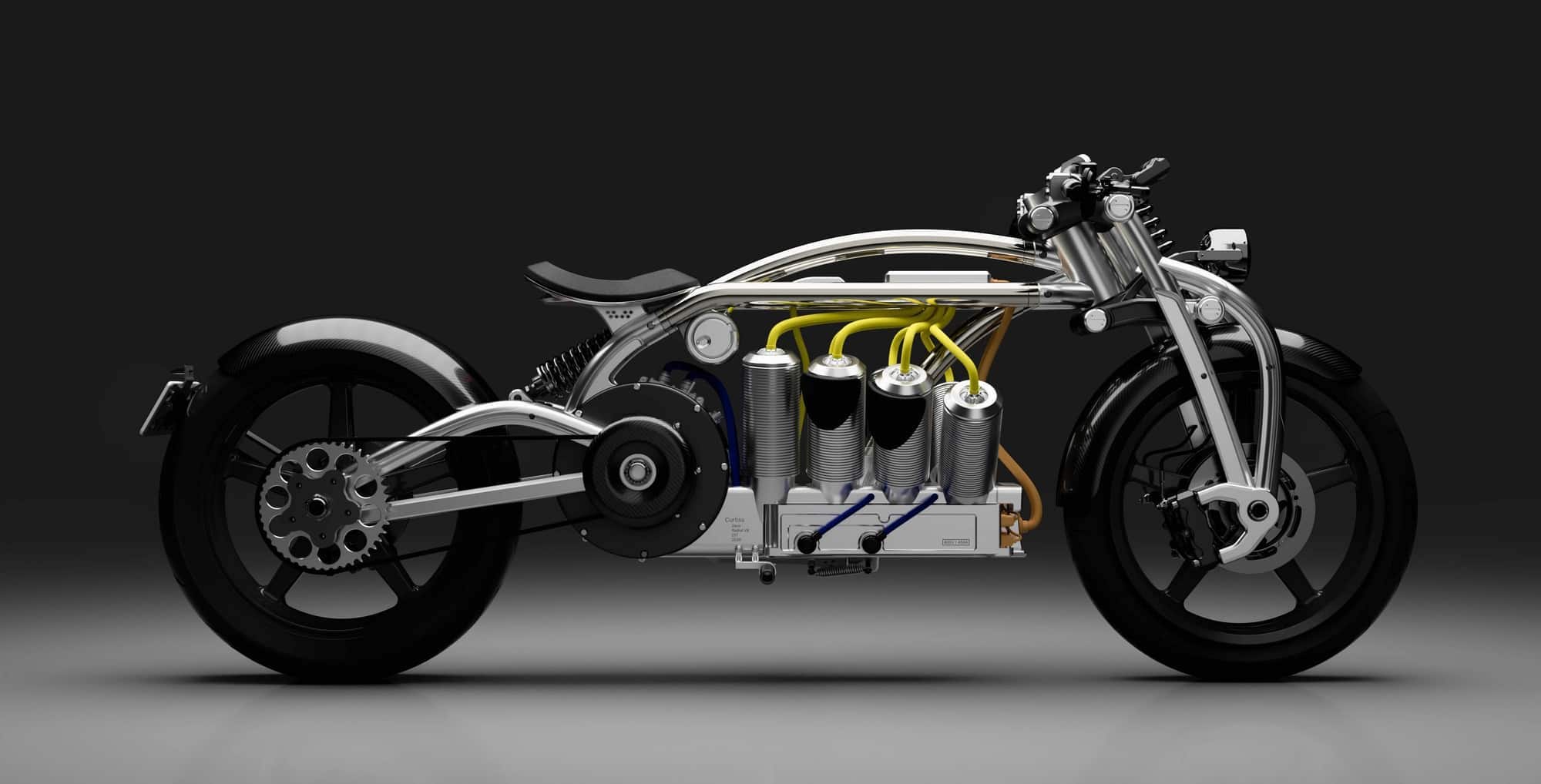

One of the first things you notice on Curtiss Motorcycles’ new Zeus 8 electric motorcycle design is a sweeping, organic-shaped chrome frame and eight banks of visible cylinders. While the uniqueness of the design is a core differentiator, Curtiss found itself struggling to come up with a strategy for producing the physical rendition of the bike design in a reasonable timeframe. With an event to showcase its new bike fast approaching, the development team ran into challenges sourcing key parts for the prototype, especially the intricate chromoloy frame. Uninterested in building out expensive tooling and lacking the time to wait…

Makerbot is building on its vision for industrial-grade desktop 3D printing with the METHOD X, what it dubs a manufacturing workstation architected for the production of end-use parts, manufacturing tools, and functional prototypes. The new desktop 3D printer’s ability to print in real ABS material in a 100°C build chamber using Stratasys SR-30 soluable supports allows dimensional accuracy and precision typically associated with higher-grade and more expensive industrial 3D printers, Makerbot officials said. Specifically, they claim METHOD X can print parts that are up to 26% more rigid and up to 12% stronger than modified ABS formulations used on most…

As advanced manufacturing introduces new challenges to traditional product development workflows, one company is touting its new platform as a more effective way to generate complex, parametric designs primed for advanced manufacturing techniques, including 3D printing. The three-year-old nTopology just released nTop Platform, a computational-based offering that integrates CAD, simulation, and computer-aided manufacturing (CAM) capabilities to help engineering teams create complex and optimized geometries that are difficult or impossible to make with traditional offerings, according to Bradley Rothenberg, the company’s founder and CEO. “The shift to advanced manufacturing is the driver that’s allowing us to innovate new engineering processes,” Rothenberg…

3D printing will continue to play a key role in HP’s mission to create a circular and low-carbon economy—a vision and set of initiatives benchmarked in its most recent 2018 Sustainable Impact Report. In addition to a commitment to increase recycled plastic content in its Personal Systems and Print products to 30% by 2025, the technology giant also set a timeline to power its global operations with 100% renewable electricity by 2035. On the recycled plastics front, HP announced it used 21,250 tonnes of recycled plastic in HP products, including more than 8,000 tonnes in its Personal Systems products (an…

Siemens took the first step toward bolstering its digital design and manufacturing portfolio with low-code application development capabilities via the integration of Mendix with its MindSphere Internet of Things (IoT) platform. The Mendix for MindSphere integrated solution brings AI-assisted, visual model-based development capabilities to the IoT world, allowing business users or design engineers without formal coding experience to create their own IoT applications. Siemens acquired Mendix last year and this is the first integration deliverable. While Siemens provides a range of out-of-box connectivity and predictive analytics functionality for its MindSphere cloud-based IoT operating system, it’s become clear that custom applications…

As part of a wide-scale effort to integrate 3D printing into all avenues of its product development and manufacturing processes, Ford is pursuing a pilot project to jump-start the design of tools and fixtures, including making it easier for plant floor workers to produce components on their own without help from experienced experts. Ford’s Cologne, Germany, pilot plant maintains a small-scale manufacturing line, which develops cars years before they go into production. As part of their efforts, the team has been honing an optimized workflow to create jigs, tools and fixtures at local plants using 3D printing techniques as opposed…

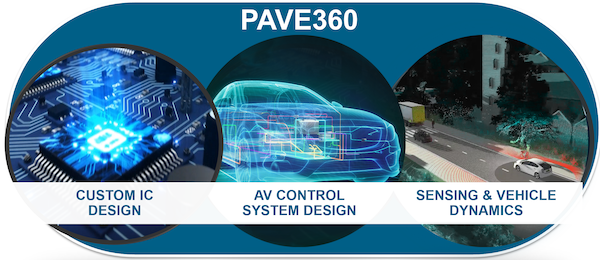

To say there’s a lot going on with autonomous vehicle development is an understatement. There’s the vehicles themselves, which include LIDAR, radar, a vast array of sensor technologies, and the sophisticated artificial intelligence algorithms that power the autonomy. There are the smart cities in which the cars will interact as part of their excursions as well as a sophisticated ecosystem of suppliers all collaborating on various aspects of a solution. For everything to come together in a timely and cost-effective fashion, there’s no question, simulation must be a foundational building block for development. While various players leverage different simulation tools…

While 3D printing is gaining ground as a manufacturing method for end-use parts and industrial tooling, companies remain stuck in the phase of deploying limited production runs, according to a new survey released by Dimensional Research and sponsored by Essentium. Nearly all (99%) of survey respondents expect use of 3D printing for production parts to increase significantly over the next three to five years and all see benefits for harnessing 3D printing for large-scale manufacturing runs. Cost savings are viewed as the most significant benefit, cited by 88% of respondents, while most also see 3D printing as a production approach…

Women make up only 13% of the engineering workforce. That’s a pretty alarming statistic, and to change it, there is an active effort underway to foster interest in engineering among young female students, including DiscoverE’s recent Introduce a Girl to Engineering Day, celebrated on February 21. Timed to last week’s event, Siemens PLM Software showcased its own rendition of a rising female engineering star: Ashley Kimbel, a senior at Grissom High School in Huntsville, AL, who tapped the firm’s Solid Edge 3D design platform to create a lighter weight prosthetic foot for a U.S. marine wounded in Afghanistan. “I’ve always…