Editors’ Picks

Found in Robotics News & Content, with a score of 38.97

Stratasys Ltd. has signed an agreement to acquire 3D printing start-up Origin Inc. in a transaction for total consideration of up to $100 million, including cash and stock. The merger enables Stratasys to expand through innovation in the mass production parts segment with a next-generation photopolymer platform. Subject to various approvals and other closing conditions, the acquisition is expected to close in January 2021. Stratasys expects Origin’s Programmable PhotoPolymerization (P3) technology to be an important growth engine for the company, adding up to $200 million incremental annual revenue within 5 years, the company says. The acquisition will help fortify Stratasys’…

Found in Robotics News & Content, with a score of 38.59

At the RAPID + TCT 2019 event, Stratasys is unveiling a supplier agreement with the New York Yacht Club, American Magic, a challenger for the 36th America’s Cup. American Magic is the combination of three racing programs and a leading yacht club—joining forces to win the America’s Cup, the highest prize in sailing and the oldest event in international sports. American Magic is using the Stratasys Fortus 450mc, which is capable of 3D printing carbon fiber reinforced FDM Nylon 12. American Magic boats are specifically designed with aerodynamics in mind, and supported by the team’s Official Innovation Partner, Airbus. The…

Found in Robotics News & Content, with a score of 37.59

Stratasys has unveiled the new J750 Digital Anatomy 3D Printer targeted to the medical industry. Designed to replicate the feel, responsiveness and biomechanics of human anatomy in medical models, the system is built to improve surgical preparedness and training while helping bring new medical devices to market faster, the company reports. The Digital Anatomy 3D Printer recreates actual tissue response - and can be used anywhere without specialized facilities. It also lets users focus on specific pathologies. “We believe in the potential of 3D printing to provide better health care, and the Digital Anatomy 3D Printer is a major step…

Found in Robotics News & Content, with a score of 35.87

Having successfully implemented Stratasys’ 3D printing to produce parts for the German and UK rail industries, Siemens Mobility Services has continued its investment in Stratasys technology to support the expansion of its rail maintenance operations in Russia. This includes two new industrial-grade Stratasys Fortus 450mc 3D Printers for part production. The decision comes in line with a recent business win for Siemens Mobility to build 13 additional high-speed Velaro trains for Russian train company, RZD, including an agreement to maintain and service the trains for the next 30 years, according to Siemens. This is already the third Velaro order from…

Found in Robotics News & Content, with a score of 35.86

Stratasys plans to remove complexity from design-to-3D print processes with its latest release. GrabCAD Print’s Advanced FDM feature is aimed at ensuring design intent via intuitive model interaction to rapidly deliver strong, light parts, Stratasys notes. By avoiding CAD-to-STL conversion, users are able to work in high fidelity and advance the design-to-3D print process, Stratasys says. Advanced FDM is designed to speed part production, while maintaining creation of purpose-built parts that minimize weight without compromising strength, according to the company. “For design and manufacturing engineers, one of the most frustrating processes is ‘dumbing down’ a CAD file to STL format,…

Found in Robotics News & Content, with a score of 35.49

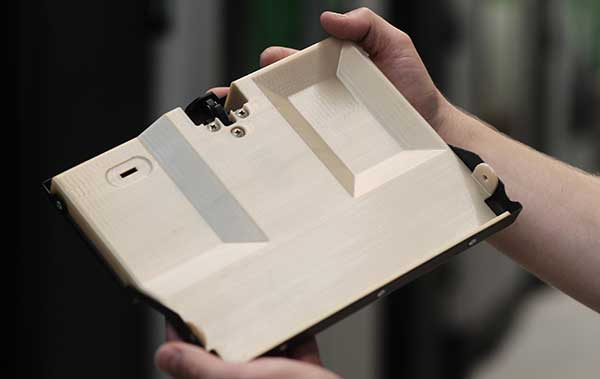

…dust extractor prototype illustrates J850 Pro 3D printer from Stratasys. Image courtesy of Stratasys. Stratasys Ltd. has unveiled a new solution in the company’s family of multi-material enterprise PolyJet 3D printers. The new J850 Pro 3D printer offers J8 series capabilities tailored specifically to engineering needs, without full color. It enables engineers to produce prototypes for concept verification, design validation and functional performance using the latest materials, including transparent VeroUltra Clear. The J850 Pro complements the existing J850 Prime for designers and engineers who also need full-color printing. With its capacity for seven materials jetted simultaneously, fast printing and high…

Found in Robotics News & Content, with a score of 35.01

At 3DEXPERIENCE World in Nashville earlier this week, Stratasys announced its new J826 3D printer. At roughly half the price of the other devices in the J8-series PolyJet line, the new model is targeted at users with more limited budgets and space. The printer provides full PANTONE-validated color and multi-material 3D printing, and is targeted at designers that need to produce rapid prototypes. According to Stratasys, the J826 is particularly suited for enterprises with mid-volume modeling requirements in industries such as consumer goods and electronics, automotive, and educational institutions. These end users can create realistic prototypes in full color using…

Found in Robotics News & Content, with a score of 34.83

…reportedly one of its largest single orders to date, Stratasys, has announced that Latvia-based specialist aerospace additive manufacturing service provider, AM Craft, has purchased four large-scale production-grade Stratasys F900 3D Printers to provide certifiable 3D printed parts for a much wider range of aircraft interior applications. This includes everything from aircraft seating, paneling and ducting, as well as making it much more affordable for its aerospace customers to introduce customization within the cabin. “In recent years, we’ve seen an ongoing demand for 3D printed production parts among major aircraft OEMs,” comments Jānis Jātnieks, co-founder and CEO, of AM Craft. “Although…

Found in Robotics News & Content, with a score of 34.47

…Aerospace and Defence is using advanced 3D printing from Stratasys to manufacture, flight-ready parts for several of its military, civil and business aircraft, while producing specific ground-running equipment at a lower cost than aluminum alternatives, the company reports. The company is a large privately owned and independent aerospace and defense companies. Marshall already has several pieces of 3D-printed ductwork flying on heavily modified aircraft, as well as holders for safety knives and switches for aircraft interiors. 3D printing flight-approved parts on demand enables the company to produce lighter parts than traditional methods. According to Chris Botting, Materials, Processes and Additive…

Found in Robotics News & Content, with a score of 31.86

…the scoops had to be manufactured quickly. According to Stratasys, IndyCar came to them for help. The scoops were 3D printed with UV-resistant ASA materials by the Stratasys Direct Manufacturing division. The entire batch of 24 units needed for the race was made in about 48 hours, with enough time to ship them to the drivers before the next race. 3D printing can’t help anybody win a race, but it’ll help the drivers stay cool, literally, in the heat of the race. The 3D printed scoops produced by Stratasys kept the cockpits cool during the July IndyCar race. Image courtesy…

Found in Robotics News & Content, with a score of 31.23

…Now, fresh off a commitment to add 17 new Stratasys FDM 3D printers, GM is expanding 3D printing into production-grade applications like tooling and parts manufacturing. Today, more than 700 GM employees are trained in the technology, and there is a significant effort underway to leverage 3D printing for the design and development of tooling to achieve time-to-market advantages, weight reduction, and cost efficiencies, according to Ron Daul, GM’s director of additive manufacturing. “Where GM is really taking off is in educating its supply base and internal folks on the tooling applications and the value to be had,” notes Fadi…

Found in Robotics News & Content, with a score of 31.17

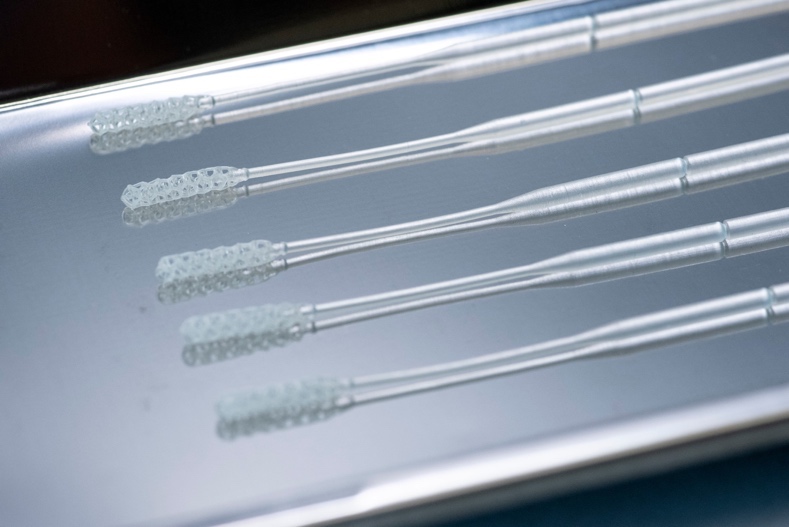

…address the shortage of nasal swabs. 3D printer manufacturer Stratasys is pooling resources with a lesser known 3D printer company to market and promote 3D printed nasopharyngeal (NP) swabs to healthcare providers and U.S. testing centers. Instead of leveraging its own 3D printer technology, Stratasys is lending its sales and marketing muscle and healthcare industry presence to start-up firm Origin, helping the firm more easily distribute Origin 3D-printed swamps. Each Origin One 3D printer has the ability to produce batches of 1,500 Origin NP 01 Swabs at a time, multiple times a day. Origin is on track to streamline processes…