Editors’ Picks

Found in Robotics News & Content, with a score of 10.95

…into soldering and welding, materials handling, assembling & disassembling, painting and dispensing, cutting and processing, milling, and others. Materials handling is the largest segment by function in the industrial robotics market. In 2012, Asia Pacific was the largest revenue generator that accounted for 49.45% of the total market share. The dominance of Asia Pacific is attributed to growth in number of countries such as China, India, Japan, Taiwan and Australia among others investing heavily in research and development infrastructure developments. Rapid growth in automation demands coupled with reduction of duties on refurbished goods has also fueled growth in the industrial…

Found in Robotics News & Content, with a score of 10.94

…to our customers,” Skuler added. “Each exhibition has famous paintings and a discussion about art.” “Finally, a fun ‘Road Trip’ experience puts our customers behind the wheel of a virtual van as they accompany ElliQ to places like the Grand Canyon or the Smithsonian museum in DC,” he said. “Like the café, these leverage the modalities of the robot to create an immersive experience.” “With the memories, we're prompting our customers with questions about their childhood (“Talk about a teacher whose legacy you carry with you”), major milestones (“What were you doing during the moon landing?”) as well as other…

Found in Robotics News & Content, with a score of 10.33

…technology is incorporated into the welding and vehicle spray painting applications deployed by Lincoln Electrics and Honda, among others. In Flaim Systems' firefighting applications as well as Sixense's training apps, the use of replica equipment plays an important role. In Flaim Trainer, users use a haptic-enabled water nozzle that can simulate water pressure. In Sixense's spray simulation application, users use an industry-standard paint gun. The incorporation of eye tracking, hand tracking, and replica equipment that help build muscle memory brings AR-VR-powered training to a new level, setting it apart from entertainment applications that focus primarily on immersive visuals. Analyst firm…

Found in Robotics News & Content, with a score of 9.68

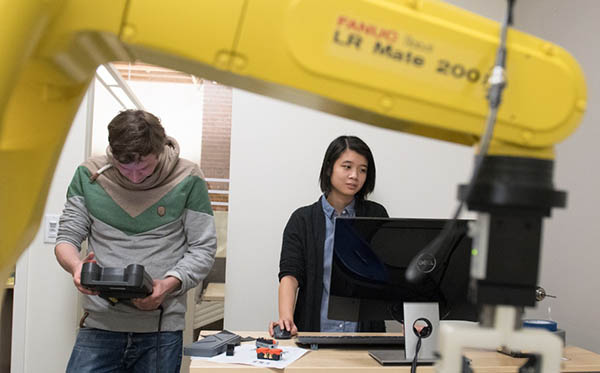

…now seeking out cobot manufacturers and partners for welding, painting, and other solutions, exhibitors said. “FANUC released our CRX robot for material handling a couple of years ago, then released our CRX collaborative arc welding robot in the middle of the pandemic, about a year ago,” said Paul Webster, CNC engineering manager at FANUC. “Now it’s really taking off.” Webster said that the CRX collaborative arc welding robot is designed for the small batch jobs, and can be quickly taught—rather than programmed—to handle different welds for different production needs. If a company has high volume, very repeatable needs, it could…

Found in Robotics News & Content, with a score of 9.46

…that's particularly good for inspections in construction, repair, and painting.” “In supply chain automation, there has been slow but steady progress bringing it into distribution centers and even shelf-stacking robots,” he said. “Stores themselves are becoming more automated—the margins are so thin in retail, it makes more sense.” “On the agriculture side, Muddy Machines, which raised $1.8 million in seed funding, makes an asparagus-harvesting robot that could be more broadly applicable to specialty crops,” Keen added. “British farms are not as centralized as other parts of the world, which provides an interesting dynamic for robotics.” “SMEs [small and midsize enterprises]…

Found in Robotics News & Content, with a score of 9.04

…safety-rated switches and sensors in place. Explosive environment (e.g. painting) Not possible for cobots: Currently no explosive environment-rated cobots. Good fit: Paint robots are readily available for this application. This high-level table is a good place to start when considering your application, but the situation becomes more complex when there are competing constraints, such as high speed and working near humans. Understand your problems Unfortunately, there is no clear-cut way of solving problems in complex categories. The best approach is to clearly understand the problem and discuss it with an automation specialist who understands implementation strategies for both cobots and…

Found in Robotics News & Content, with a score of 9.03

…ElliQ taking users to museum exhibits and road trips, painting with ElliQ using generative AI, and exercises led by a certified mindfulness instructor. The social robot can also record life memories in a digital memoir and share them with family and friends. ElliQ also enables NYSOFA staffers to send informational video messages about available resources, said Intuition Robotics. The company has won several awards for its work with ElliQ, including Fast Company’s Most Innovative Companies and the CES Best of Innovation award. Click on image to enlarge. Source: Intuition Robotics and NYSOFA New York residents see reduced loneliness According to…

Found in Robotics News & Content, with a score of 8.83

…from the auto industry. As an example, automating the painting process of automobiles has taken the employees out of poor working conditions where they were exposed to hazardous fumes and provided a much more consistent painting application. Automobile painting by robots provides far superior quality. Another example is the reduction in repetitive stress disorders in employees. Relieving employees from tedious assembly lines with automation reduces the incidents of injury and increases the quality of assembly by using robots that consistently perform the same tasks the same way each and every time. Automation Software Improving Quality Understanding the value of flexible…

Found in Robotics News & Content, with a score of 8.69

…can be applied to allied activities such as insulation, painting, and other material transport, said KEWAZO. The company said its vision is to automate and digitize all on-site logistics, from the arrival of materials at the construction site to their use. Investors support construction robotics Fifth Wall led KEWAZO's Series A, with participation from from Cybernetix Ventures and Unorthodox Ventures, as well as construction software company Nemetschek. Existing investors True Ventures and MIG Capital AG also participated in the round. KEWAZO previously closed a $5 million in pre-Series A funding in September 2021. “Labor shortage and pressure on productivity continues…

Found in Robotics News & Content, with a score of 8.57

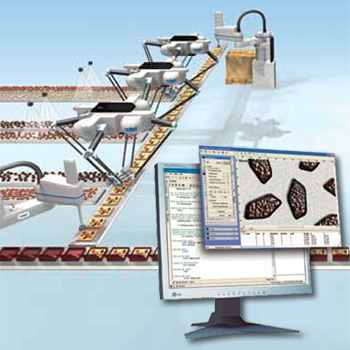

…software,” Allard said. “This is useful for applications like painting or dispensing. You can also quickly make a pick-and-place application or create a part reference frame that fits the real part position.” RoboDK said its team hopes to see a variety of innovative use cases and success stories from its user base. It is also working to make the system even easier to adopt by creating step-by-step setup guides for users looking to construct their own probes. The company said these initiatives reflect its “commitment to empowering users with valuable resources and fostering a culture of innovation and knowledge exchange.”

Found in Robotics News & Content, with a score of 7.83

…well-developed traction in three vertical segments: Automotive welding and painting, where we decrease robotic system lifecycle costs by upwards of 50% while increasing throughput rates by 10% to 30% with our RapidPlan autonomous path-planning product. Mixed-case palletizing, where we increase throughput rates by 20% to 40% through autonomous path planning for multiple robots, and massively decrease error driven down-time through closed-loop monitoring of the actual build to prevent time-consuming crashes between robots and things that may have shifted on the pallet after placement. Digital twin simulation of the robotic component of automation systems, where we provide autonomous path planning for…

Found in Robotics News & Content, with a score of 7.76

…wide range of industry for tasks from welding to painting to material handling. Industrial robots in automotive assembly. Source: SwRI Traditional robots are isolated from humans by cages with complex safety systems in place to ensure that workers cannot be injured while the robot is moving. This is essential because a traditional robot is a heavy piece of machinery moving at high speeds. Without a safety system in place, an industrial robot can easily injure or kill someone if they accidentally move into its path. With enough safety measures, it is possible to incorporate most traditional industrial robots into a…