Editors’ Picks

Found in Robotics News & Content, with a score of 31.86

…and a large showroom filled with robotic and CNC machine demonstrations. FANUC Mexico will demonstrate a variety of automation technologies designed to help customers increase their production capabilities, overcome labor challenges, and remain competitive, including: Collaborative tote picking —A FANUC CR-15iA collaborative robot using an overhead-mounted iRVision 3DV/600 Vision Sensor will pick random consumer products from a tote and place them into an outfeed tote. It will demonstrate the sensor's speed and accuracy, as well as its ability to detect and pick a variety of products, similar to applications found in warehousing and distribution. Hands-on collaboration —A FANUC CRX-10iA cobot…

Found in Robotics News & Content, with a score of 31.85

…May 1. “The industrial sector is looking to automate machine tending but lacks the people to develop, design, and implement the automation solutions.” “We manufacture complete robot cells that have a delivery time of 14 days and can then be installed and safety approved in just 24 hours,” he added. “When customers receive a delivery from us, it arrives in a large wooden crate and is then up and running and generating value the very next day.” Lachenmeier, who is a third-generation entrepreneur, founded EasyRobotics in 2014. Kjempff joined the company in 2018 and took responsibility for ensuring that EasyRobotics…

Found in Robotics News & Content, with a score of 31.50

…uses that can be seen include the OB7 CNC machine tending on a mill, an application enabled by Productive Robotics’ OB7 CNC Package. The package comes equipped with a 7-axis collaborative robot arm as well as all the necessary accessories needed to connect to any type of CNC mill, lathe, or other CNC machine. Another application being shown is OB7’s standard 5 kg model loading and unloading parts in and out of a milling machine. The largest model of the 7-axis cobot line, OB7-Max 12, can be used to palletize boxes. With a 12-kg payload capacity and a 1.3-meter reach,…

Found in Robotics News & Content, with a score of 31.15

Yaskawa and Clearpath have partnered to develop a mobile machine tending and material movement solution ideal for shop floor environments. This fully integrated solution will feature a Motoman MH12 robot equipped with end-of-arm tool and vision system, mounted on Clearpath’s OTTO 1500 self-driving vehicle. This project is currently under development and supported under the advanced research division of Clearpath. “Our partnership with Clearpath will provide industry with a robust, tightly integrated solution for moving robots to the work in a very flexible and dynamic way,” said Roger Christian, divisional leader, new product development at Yaskawa Motoman. “This autonomous modular solution…

Found in Robotics News & Content, with a score of 30.32

…America. The collaborative robot is strong enough to perform machine tending with heavy metal and plastic parts and precise enough to carry out pick-and-place tasks at high payloads, said the company. “The KR1018 is a very strong, compact cobot with a weight of only 34 kg [74.9 lb.], ideal for performing various jobs at industrial companies,” said Dieter Pletscher, head of global sales at Kassow Robots. “SMEs [small and midsize enterprises] without their own robotics specialists can achieve complex automation and programming cost-effectively and independently with the KR1018.” Kastrup, Denmark-based Kassow Robots designs and manufacturers seven-axis lightweight robots for industrial…

Found in Robotics News & Content, with a score of 29.56

…to utilizing motion offerings tailored to human needs. From machine tending to palletizing, welding, and F&B services, the company said it offers a diverse array of ready-to-sell solutions catered to both domestic and global markets. That is why Doosan Robotics’ theme at Automate 2024 is “The Motion Platform Company.” At the show, Doosan Robotics unveiled its latest industrial cobot with new capabilities. The cobot comes with a 30 kg (65 pound) payload. Doosan Robotics booth will feature Dart-Suite, an advanced robot ecosystem designed to redefine the way customers utilize Doosan cobots. The scalable platform elevates cobot capabilities by providing unlimited…

Found in Robotics News & Content, with a score of 29.35

…and repetitive tasks that require long reach, such as machine tending, assembly, quality assurance, or pick-and-place tasks, according to Kassow Robots. The KR1805 has a reach of 1,800 mm and can handle a payload up to 5 kg. Source: Kassow Robots The robot's seventh axis, or “wrist joint,” enables continuous dispensing, welding, and material removal applications, regardless of access angle, without the need to reorient the arm, said the company. The seventh axis also gives the KR1805 a small footprint of 160 x 160 mm (6.2 x 6.2 in.). This provides “a huge advantage in maneuverability” and an increased range…

Found in Robotics News & Content, with a score of 28.91

…for applications such as packaging, quality control, materials handling, machine tending, packaging, assembly, and surface finishing. MAP to make applying OnRobot tooling easier Vention said MAP provides users with the engineering software and modular hardware they need to design, automate, order, and deploy factory equipment in a single digital environment. With thousands of modular parts, smart design tools, and real-time pricing, factory equipment can be designed in minutes from anywhere, on any web browser, it said. The addition of OnRobot’s plug-and-play tools for collaborative and light industrial robots will allow manufacturers to focus on scaling production with greater flexibility and…

Found in Robotics News & Content, with a score of 28.90

…options at the show represent applications such as welding, machine tending and material removal give manufacturers flexibility and advanced capabilities when choosing automation to meet their diverse needs. CL Series creates “new era” of collaborative automation Developed in partnership with NEURA Robotics, the CL Series cobots challenge the current understanding of collaborative robots, according to the companies. The CL Series offer full-on industrial scale performance and speed paired with maximum protection without compromising the safety and flexibility advantages of human/robot collaboration. “Kawasaki Robotics is committed to delivering the advanced automation technology manufacturers need to maintain production schedules without having to…

Found in Robotics News & Content, with a score of 28.65

…now have the ability to control connected robots providing machine tending or other assistance through FANUC’s Quick and Simple Startup of Robotization (QSSR). More manufacturers are adding robots to execute repetitive tasks previously performed manually, noted FANUC America. Advanced automation offers shops of all sizes a competitive edge and greater profit margins, according to the company. FANUC’s QSSR is a package intended to simplifies the connection of a FANUC robot to a FANUC controlled machine tool. The new QSSR G-code feature allows operators and machine tool builders to program robots easily through the FANUC CNC in ISO standard G-code format.…

Found in Robotics News & Content, with a score of 28.51

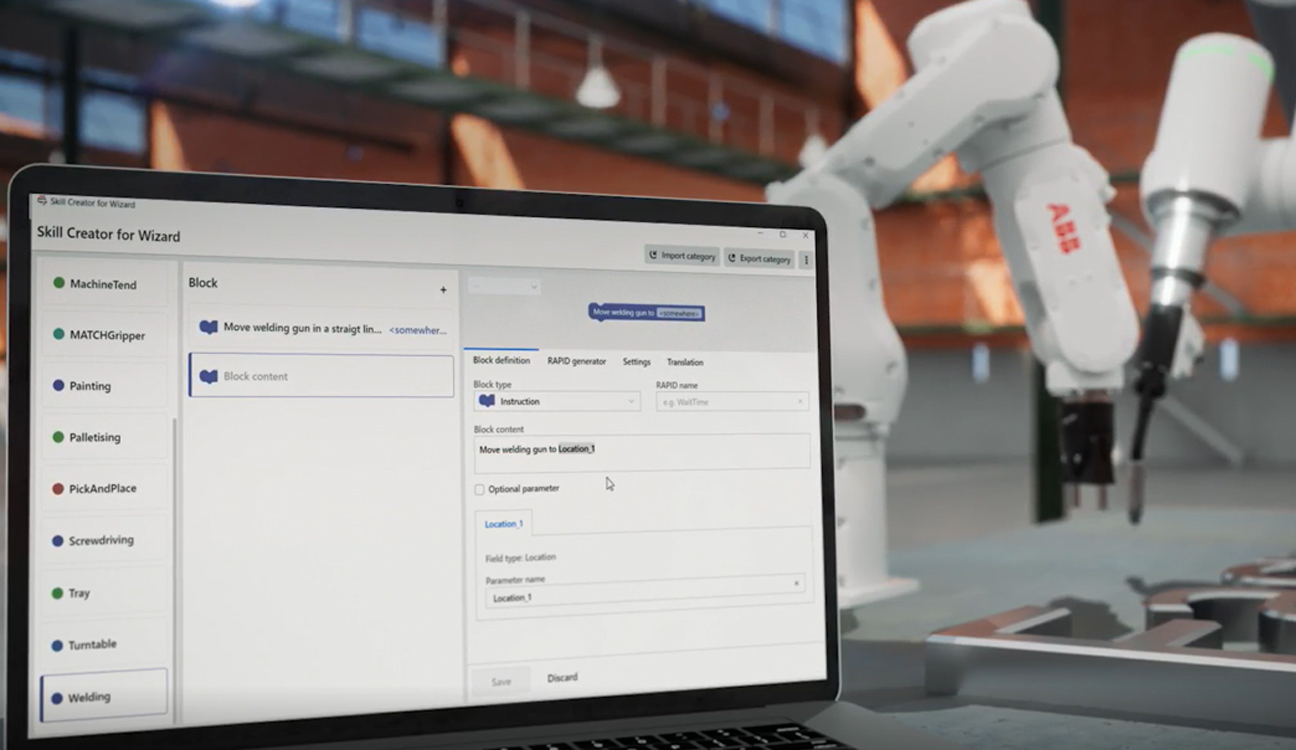

…to develop robot applications such as arc welding or machine tending. It also increases operational flexibility, allowing users to modify existing programs and pre-programmed blocks that control various behaviors, ranging from robot movements to signal instructions and force control, through its intuitive graphical user interface. Catering to novice and experienced users, Wizard Easy Programming comes with Skill Creator, a tool that helps system integrators and other expert users efficiently create customized, application-specific Wizard blocks for their customers' use. Skill Creator can simplify the creation of highly-specific tasks like machine tending and welding as well as intricate applications such as medical…

Found in Robotics News & Content, with a score of 28.45

…cobot workcell’s productivity, while overcoming the ‘labor gap’ in machine tending manufacturing operations.” Applied Cobotics Cobot Feeder standardizes part loading Since 1983, PBC Linear (Pacific Bearing Co.) said it has created and patented linear motion systems and has greatly expanded its technology, expertise, and services. Through its partnerships in Europe and Asia and its worldwide network of distributors, the company added that it is a trusted global leader in bearing products. The Applied Cobotics Cobot Feeder includes a base storage-and-retrieval unit with a Universal Robots (UR) collaborative robot pedestal, an enclosed steel rack dunnage tower that can store up to…